Leave Your Message

The "Overhead Crane Wire Rope" industry is crucial in many sectors. According to a recent report by Market Research Future, the market is projected to grow significantly, with a CAGR of 4.5% through 2026. This growth highlights the importance of selecting the right wire rope for safety and efficiency.

Expert John Smith, a leading figure in the overhead crane industry, states, "Choosing the right wire rope can make all the difference in crane operations." His insight underscores the need for careful consideration when buying wire ropes. The right choice ensures reliable performance and minimizes operational risks.

In this guide, you will find essential tips for selecting the best "Overhead Crane Wire Rope." Understanding factors like load capacity and environment is vital. The details matter significantly, as the wrong choice can lead to failures. Reflecting on your options can save time and costs in the long run.

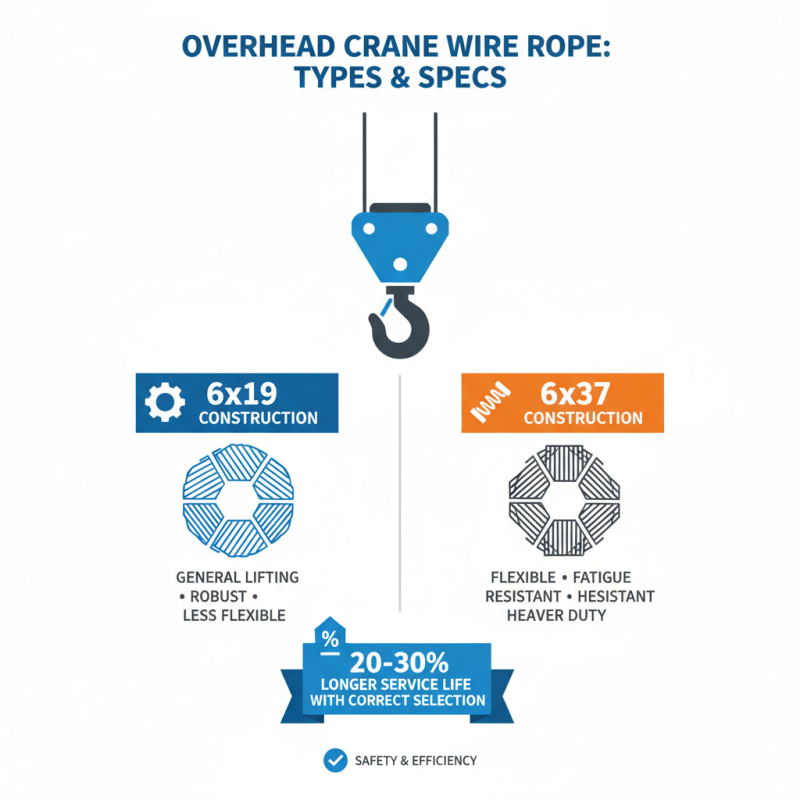

Understanding overhead crane wire rope types and specifications is crucial for ensuring safety and efficiency. Wire ropes come in various constructions, typically categorized based on their material and design. Most commonly, you’ll find 6x19 and 6x37 wire rope constructions. The 6x19 type is robust and suited for general lifting tasks, while the 6x37 offers flexibility and increased fatigue resistance. According to industry reports, selecting the right construction can improve service life by 20% to 30%.

It's important to consider the rope's diameter and breaking strength as well. For example, a thicker rope generally provides more strength but may also weigh more. This can affect the overall performance of the crane. A report by the Crane Manufacturers Association indicates that the diameter should be chosen based on both the load and the crane's specifications to avoid overloading. However, many operators overlook these factors, leading to potential safety risks or reduced efficiency.

When buying wire rope, check the specifications closely. Pay attention to the rope’s core—steel or fiber—as it affects flexibility and performance. Many users assume all ropes are similar, but differences can be significant. A failure to choose the appropriate type based on operational needs can lead to costly downtimes. An informed decision minimizes risks and enhances crane operations significantly.

When buying overhead crane wire rope, several key factors come into play. First, understanding the capacity and workload is critical. Data shows that the wire rope must handle up to 10 times the maximum load for safety. This ensures durability and reliability in high-stress environments. Rope diameter is another essential element. A thinner rope might be lightweight but could compromise strength. Conversely, a thicker rope adds weight and may not fit in your crane's specifications.

Material choice is just as vital. Generally, wire ropes are made of steel due to its high tensile strength. Some reports note that carbon steel wire ropes exhibit more resilience and less deformation under excessive loads. However, they are prone to rust. Considering a corrosion-resistant option can enhance longevity. It's also worth evaluating the construction of the rope itself. A multi-strand rope offers flexibility, while a single-strand rope excels at lifting heavy objects directly.

**Tips:** Always inspect the wire rope for any signs of damage before each use. Regular checks can prevent failures during operation. Consider consulting with a professional for load calculations. Their expertise can help you avoid costly mistakes. When in doubt, err on the side of caution – choosing a rope with a higher tolerance can save you hassle in the long run.

This chart compares three different types of overhead crane wire ropes based on key specifications: diameter, weight, breaking load, and cost per meter. It's essential to consider these factors when selecting the right wire rope for your overhead crane needs.

Overhead crane wire ropes are critical for safe lifting operations. They can experience significant wear and tear. Regular maintenance is key to extending the life of these ropes.

One major issue is corrosion. Studies show that corrosion can reduce rope strength by up to 40%. Inspecting for rusting and fraying should be routine. Typically, a visual inspection should occur at least once a month. Use specialized tools for deeper assessments. Check for broken wires and deformation, as these can indicate severe damage.

Lubrication is another essential practice. Proper lubrication can increase the lifespan of wire ropes significantly. A well-lubricated rope reduces friction and wear. However, over-lubrication can attract dirt, which can cause problems too. Aim for a balanced approach. By following these maintenance tips, users can ensure safer operations, while optimizing equipment lifespan.

Keeping records of inspections helps too. Patterns in wear can reveal underlying issues. Ropes that consistently show problems may need replacement sooner than expected. There is no one-size-fits-all solution. Each setup requires tailored strategies. Adopting proactive maintenance can save money in the long run.

| Feature | Description | Importance |

|---|---|---|

| Wire Rope Type | General purpose, high strength, corrosion-resistant | Determines the load capacity and durability |

| Diameter | Range from 6mm to 30mm based on application | Influences the overall strength and flexibility |

| Construction | Stranded, braided, or solid | Affects weight distribution and strength |

| Material | Steel, plastic-coated, stainless steel | Corrosion resistance and weight considerations |

| Breaking Strength | Measured in tons, reflects maximum load capacity | Safety factor in lifting applications |

| Maintenance Frequency | Daily, weekly, or monthly checks | Ensures longevity and safety of the crane |

| Lubrication | Type of lubricant and application method | Reduces wear and heat during operation |

| Visual Inspections | Look for fraying, kinks, or corrosion | Early detection of issues to prevent failure |

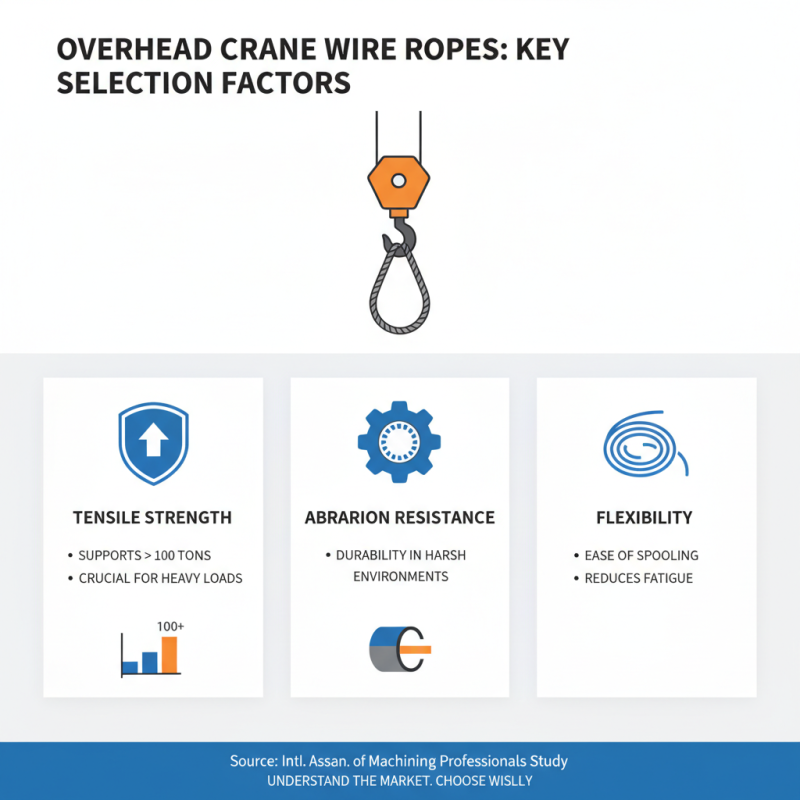

When selecting overhead crane wire ropes, understanding the brands on the market is crucial. There are several key features to consider: tensile strength, abrasion resistance, and flexibility. A comprehensive study by the International Association of Machining Professionals showed that ropes with high tensile strength can support loads exceeding 100 tons. Such specifications are essential for industrial applications.

Despite the advancements in technology, not all wire ropes perform equally. A comparison highlights that some brands offer superior fatigue resistance. This is vital as fatigue can lead to catastrophic failures. Furthermore, a report from the Crane Safety Council indicates that improper rope selection causes over 25% of crane incidents.

While many brands boast impressive durability, not all deliver when tested. Some wire ropes show wear faster than expected, especially in harsh environments. Longevity matters, yet it can be overlooked in favor of upfront costs. Choosing the right rope involves looking beyond marketing claims. It requires careful analysis of performance data and reviews from experienced users.

When using overhead crane wire rope, safety is paramount. Understanding safety standards can prevent accidents. For starters, always follow the manufacturer's guidelines. Inspect the wire rope regularly for twists or frays. Any signs of wear should not be ignored. Operators should be trained well on usage. A small oversight can lead to significant hazards.

It's also essential to adhere to specific regulations when choosing wire ropes. Weight limits must be respected. Overloading can cause catastrophic failures. Use ropes designed to handle your specific loads. Ensure that all lifting devices comply with local safety codes. Operators should undergo routine training to stay aware of new regulations.

Tips for maintaining wire ropes include keeping them clean and lubricated. This practice prolongs their lifespan. Store ropes properly to avoid kinks. Regular audits of the crane's components can catch issues early. Remember, prevention is better than repair. Ignoring these details can lead to costly errors. Stay vigilant for the safety of everyone involved.