Leave Your Message

In the world of material handling, Overhead Crane Wire Rope plays a crucial role. This equipment is vital for lifting heavy objects safely and efficiently. Various types of wire ropes are designed for specific applications, enhancing safety and productivity.

Understanding the differences among these ropes is essential. For example, some wires offer high flexibility, while others boast increased strength. Choosing the right type can prevent accidents. Ignoring these details could lead to costly errors.

As we explore the landscape of Overhead Crane Wire Rope, we must identify which type suits our needs best. By paying attention to specific characteristics, we can optimize performance. It is not just about lifting; it’s about doing it right. Let’s delve deeper into these wire rope types and their uses in 2026.

In 2026, various wire rope types dominate the overhead crane industry. These ropes are vital for ensuring safety and efficiency. Different applications demand specific features. For instance, high-strength ropes are preferred in steel plants. They withstand heavy loads and harsh conditions.

Another popular type is the wire rope with anti-twist features. These ropes prevent rotation, making them ideal for hoisting tasks. Their specialized design reduces wear and tear. Construction sites benefit greatly from using these ropes. Workers find them reliable and safe.

Despite advancements, challenges remain. Users often overlook maintenance. Ropes can degrade faster without proper care. Regular inspections are crucial. An unrecognized issue in wire ropes can lead to accidents. This emphasizes the need for awareness in wire rope applications. Even with the best materials, safety should be the priority.

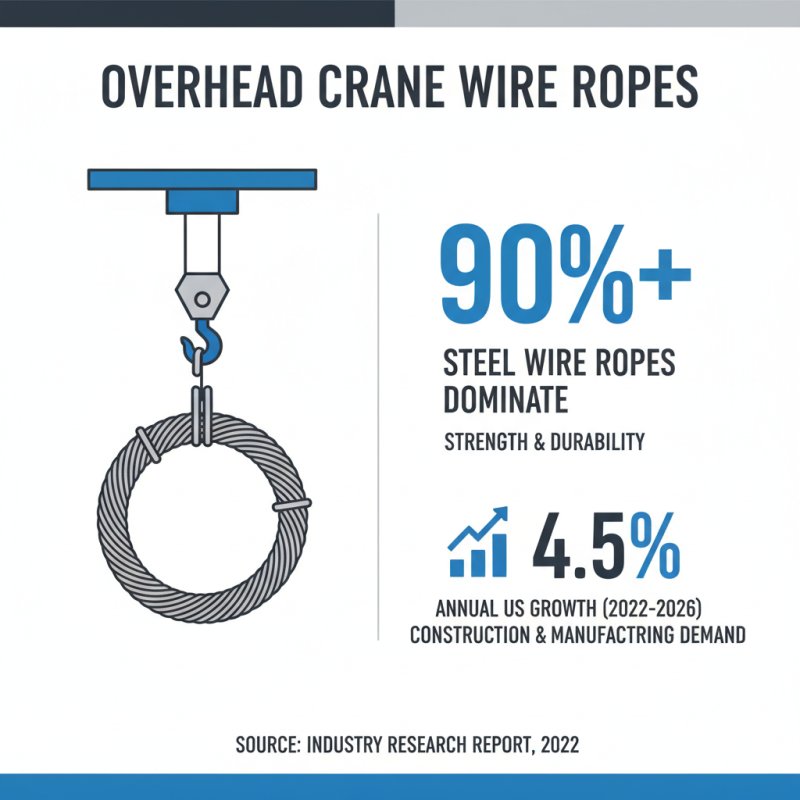

When it comes to overhead cranes, the wire rope type is crucial. Steel wire ropes dominate this category due to their strength and durability. In the United States, the market for these ropes is projected to grow at a rate of 4.5% annually until 2026, according to a recent research report. This growth is driven by increasing demand in construction and manufacturing sectors.

Steel wire ropes offer key characteristics tailored to the heavy lifting demands of cranes. They generally consist of several strands wound around a core, providing flexibility and tensile strength. Many models feature a compact design, allowing for easier spooling and handling. Commonly, the wire diameter ranges from 3mm to 20mm, depending on load capacity. These ropes can withstand heavy loads, often rated up to 300 tons. However, the ropes suffer from wear and tear due to environmental conditions and operational stress.

Regular inspection is essential to ensure safe operation. Operators must be aware of signs of damage, such as fraying or broken wires. Neglecting maintenance can lead to catastrophic failures. Additionally, adaptability is a key concern. Different lifting tasks may require different rope configurations, and this can complicate selection. Understanding the characteristics of steel wire ropes will lead to better decisions and improved safety in crane operations.

In material handling, selecting the right wire rope type is crucial. Different applications require specific wire rope characteristics. For instance, steel wire ropes are commonly used for overhead cranes in industrial settings. They offer high strength and durability, making them ideal for heavy loads. According to industry reports, steel wire ropes can lift weights up to 100 tons.

On the other hand, synthetic wire ropes, such as those made from polypropylene, provide lightweight solutions. They are often used in marine applications or environments where rust resistance is essential. Recent data suggests that synthetic ropes can reduce overall crane weight by approximately 30%. This can enhance maneuverability and reduce strain on lifting equipment.

Moreover, the choice of wire rope affects operational efficiency. Using the wrong type can lead to frequent replacements and safety hazards. For example, a poorly selected wire rope may fray quickly or even snap under load. These issues highlight the importance of understanding wire rope applications. Evaluating factors such as load capacity, environment, and frequency of use is vital for improving safety and productivity in material handling operations.

This chart illustrates the number of common applications for different types of wire ropes used in overhead cranes. Steel wire ropes are widely used due to their strength, followed by stainless steel and plastic coated variants.

When selecting wire ropes for overhead cranes, performance metrics are crucial. Strength is a primary factor. High tensile strength ensures that the wire rope can handle heavy loads without failure. Some ropes can bear tons of weight, ensuring safety in operations. However, not all applications require maximum strength. It’s essential to match the wire rope's strength to the specific load demands.

Flexibility is another vital performance metric. A flexible wire rope can easily navigate pulleys and bends. This flexibility contributes to the effective operation of cranes in tight spaces. However, excessive flexibility may reduce strength. Finding the right balance is necessary. Longevity also plays a critical role. Durable materials resist wear and tear, reducing replacement frequency. But, even robust ropes can fail under constant stress. Regular inspections are necessary to identify wear early.

The interaction between these performance metrics needs careful consideration. It's easy to prioritize one aspect while neglecting others. This can lead to operational inefficiencies. Choosing the right wire rope involves more than just looking at numbers. Real-world testing and adjustments are essential. Each application presents unique challenges, highlighting the need for continuous reflection on chosen materials and methods.

The future of overhead crane wire rope technologies is evolving rapidly. With advancements in materials, engineers are developing lighter and stronger ropes. This shift is driven by the need for increased efficiency. According to a recent industry report, synthetic fiber ropes could reduce weight by up to 40%. This reduction can enhance load capacity and operational safety.

Innovations in coating technologies are also crucial. Enhanced coatings improve abrasion resistance and longevity. This feature becomes increasingly important as cranes operate in harsh environments. Moreover, the integration of smart sensors into wire ropes is on the rise. These sensors monitor tension and wear, providing real-time data. This data can help prevent accidents and extend the ropes' lifespan.

However, challenges persist. The initial cost of advanced materials and technologies can be high. Many companies hesitate to invest without clear ROI. Industry experts suggest that long-term benefits, such as reduced maintenance costs, often outweigh these concerns. Loading safety and efficiency remain top priorities. Failing to adopt new technologies might mean falling behind competitors. Embracing these innovations is not merely a trend but a necessity for survival in the industry.

| Wire Rope Type | Diameter (mm) | Breaking Load (ton) | Common Applications | Future Trends |

|---|---|---|---|---|

| Six Strand Wire Rope | 12 | 5.0 | Construction, Shipbuilding | Increased flexibility and corrosion resistance |

| Multifilament Wire Rope | 10 | 3.5 | Mines, Energy Sector | Emphasis on lightweight and high-strength materials |

| Wire Rope with Lubrication | 14 | 6.0 | Heavy Lifting, Factory Automation | Improved durability with self-lubricating properties |

| Fiber Core Wire Rope | 16 | 7.0 | Theatrical Rigging, Event Management | Focus on sustainability and eco-friendly materials |

| Compact Strand Wire Rope | 18 | 8.5 | Bridge Construction, Heavy Machinery | Emerging technologies for increased load capacity and reduced weight |