Leave Your Message

The versatility and widespread application of 304 Stainless Steel Flat are well-recognized in various industries due to its combination of excellent corrosion resistance and formability. According to a recent report by the International Stainless Steel Forum, type 304 stainless steel accounts for approximately 50% of global stainless steel consumption, highlighting its popularity and demand in sectors such as construction, automotive, and food processing. This material is renowned not only for its aesthetic appeal but also for its durability and strength, making it a preferred choice for a range of products, from kitchenware to structural applications.

The utility of 304 Stainless Steel Flat extends beyond its physical properties; it also offers significant advantages in processing and fabrication. Industries benefit from its ability to be easily welded and shaped while maintaining mechanical integrity. Furthermore, data from industry analysis indicates that the stainless steel market is projected to grow at a CAGR of around 5% over the next five years, further solidifying the importance of 304 Stainless Steel Flat in meeting the increasing demands across diverse applications. In this context, understanding the characteristics and benefits of 304 Stainless Steel Flat becomes crucial for professionals seeking reliable materials for their projects.

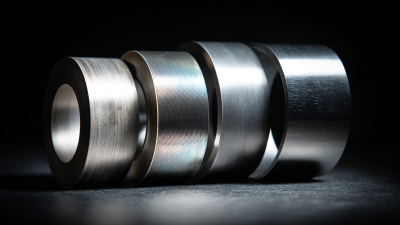

304 stainless steel flat refers to flat products made from 304 grade stainless steel, known for its excellent resistance to corrosion and oxidation. This material is primarily composed of iron, chromium, and nickel, which provide strong durability and enhance its strength, making it suitable for various applications. It is often available in different thicknesses and widths, allowing for versatility in design and construction. Its smooth surface finishes can also help in enhancing both aesthetic and functional properties.

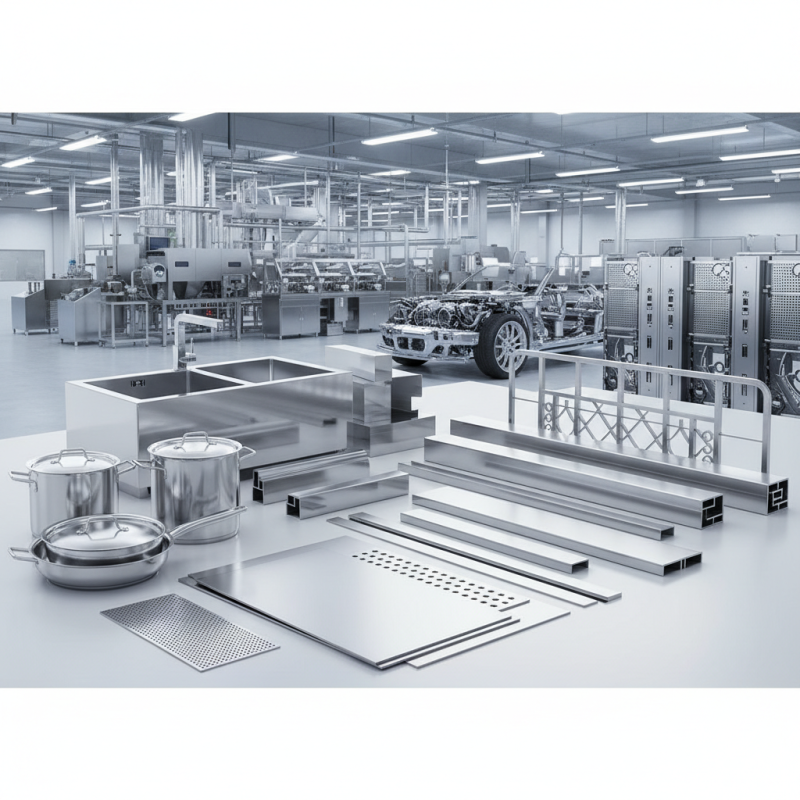

Due to its properties, 304 stainless steel flat is widely utilized across multiple industries. Common applications include construction materials, architectural components, and kitchen equipment, where cleanliness and resistance to rust are paramount. It is often used in the food and beverage industry for its ability to maintain hygiene standards; equipment made from this material can withstand frequent cleaning without degrading. Additionally, its good weldability and formability make it an ideal choice for manufacturing custom shapes and components, thus expanding its usage in various engineering and fabrication projects.

304 stainless steel is an austenitic alloy known for its excellent corrosion resistance and high ductility, making it a popular choice for various applications. The composition of 304 stainless steel typically includes 18% chromium and 8% nickel, which contribute to its remarkable ability to withstand oxidation, as well as its overall strength. These elements not only enhance its durability but also provide a shiny, attractive finish, making it aesthetically pleasing for many decorative purposes.

In addition to its corrosion resistance, 304 stainless steel exhibits good weldability and formability. This allows it to be easily shaped into different forms and welded into various configurations, which is particularly beneficial in industries like construction and manufacturing. Its non-reactive nature ensures that it is safe for food contact and is commonly used in kitchen equipment, such as sinks and countertops, as well as in chemical containers and equipment. Overall, the composition and properties of 304 stainless steel make it an ideal material for a broad range of industrial and consumer applications.

304 stainless steel flat is a versatile material widely used across various industries due to its excellent corrosion resistance and good weldability. This type of stainless steel is particularly popular in the food processing, chemical, and pharmaceutical industries, where hygiene and resistance to harsh environments are paramount. Its durable nature ensures longevity and reliability, making it an ideal choice for equipment that must withstand extreme conditions.

In the construction and architecture sectors, 304 stainless steel flat is often utilized for structural components, handrails, and decorative applications. The material offers a sleek finish that not only enhances aesthetic appeal but also provides strength and stability. In the automotive industry, parts made from 304 stainless steel flat can be found in exhaust systems and other components that require resistance to corrosion and high temperatures.

Tips: When selecting 304 stainless steel flat for your project, consider the thickness and finish that best suits your specific application. Additionally, ensure proper handling and maintenance to preserve its properties over time, particularly in environments prone to abrasion or chemical exposure. Always consult with industry professionals to determine the best practices for utilizing this material effectively.

| Application | Industry | Benefits | Size Range (inches) |

|---|---|---|---|

| Kitchen Equipment | Food Service | Corrosion Resistance | 0.125 - 2.0 |

| Chemical Storage Tanks | Chemical Industry | Durability | 0.062 - 0.500 |

| Architectural Features | Construction | Aesthetic Appeal | 0.020 - 0.250 |

| Automotive Parts | Automotive | Recyclability | 0.030 - 0.500 |

| Medical Devices | Medical | Biocompatibility | 0.020 - 0.250 |

| Oil and Gas Pipelines | Energy | High Strength | 0.125 - 0.750 |

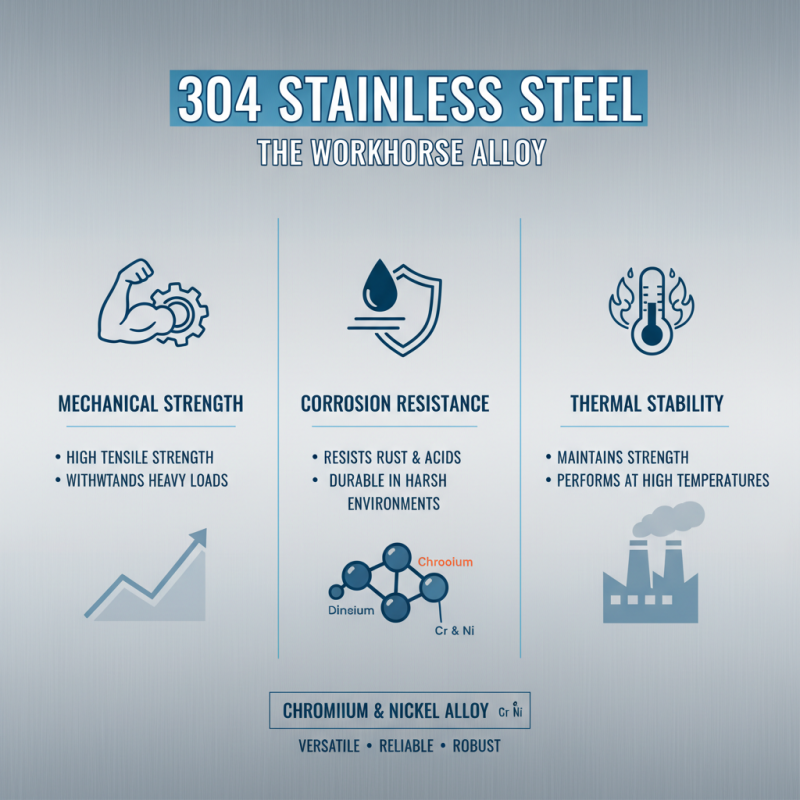

304 stainless steel flat provides numerous advantages over other materials, making it a popular choice across various industries. One of the primary benefits is its excellent corrosion resistance, which can be attributed to its high chromium content—typically around 18%—and nickel content of about 8%. According to the International Stainless Steel Forum (ISSF), 304 stainless steel is one of the most widely used stainless steel grades, constituting nearly 50% of the global stainless steel market. This level of corrosion resistance is vital for applications in environments with moisture or harsh chemicals, such as food processing and medical equipment.

Another significant benefit of 304 stainless steel flat is its superior strength and durability. With a tensile strength of approximately 70,000 psi, it provides mechanical performance unmatched by many standard materials, such as aluminum or carbon steel. The American Iron and Steel Institute (AISI) reports that 304 stainless steel also maintains its integrity under high temperatures, making it suitable for applications that require heat resistance. This combination of strength, lasting performance, and resistance to oxidation adds to its appeal, especially in demanding sectors like construction, automotive, and aerospace, where safety and reliability are paramount.

304 stainless steel is renowned for its exceptional mechanical and corrosion resistance properties, making it a popular choice in various applications. This austenitic alloy contains chromium and nickel, which contribute to its strength and durability. The material exhibits excellent tensile strength, allowing it to withstand heavy loads without deformation. Its ability to maintain structural integrity under high temperatures further enhances its versatility across different industries.

Corrosion resistance is a key feature of 304 stainless steel, enabling it to perform well in harsh environments. It resists oxidation and pitting caused by moisture and corrosive agents, which is critical for applications in food processing, chemical manufacturing, and construction. The protective oxide layer that forms on its surface acts as a barrier against rust, prolonging the lifespan of products made from this material. Additionally, its ease of fabrication allows for intricate designs and forms, making it suitable for a wide range of uses, from kitchenware to industrial equipment.