Leave Your Message

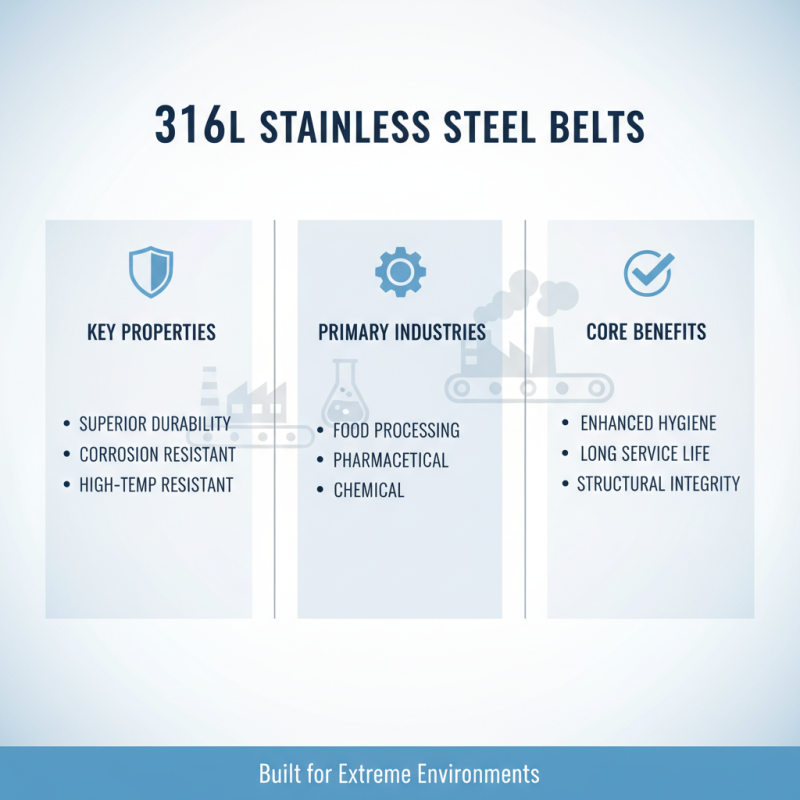

The 316L stainless steel belt has gained significant attention in various industries due to its unique properties. According to John Smith, a leading expert in materials engineering, "The 316L stainless steel belt offers unparalleled durability and resistance to corrosion." This reflects the essential nature of this material in demanding environments.

The benefits of a 316L stainless steel belt are numerous. It withstands harsh conditions, making it ideal for construction and manufacturing. Its smooth surface and flexibility further enhance its functionality. However, not all applications may benefit equally. Users should evaluate their specific needs carefully.

While the advantages are clear, challenges exist. Cost considerations can be a factor for some companies. Additionally, understanding the maintenance of a 316L stainless steel belt can be complex. It's crucial to educate teams about proper care to maximize longevity. This balance of advantages and challenges makes the 316L stainless steel belt a topic worth exploring deeply.

316L stainless steel belt is a high-quality material known for its durability and resistance to corrosion. Made from a specific alloy, it contains molybdenum, which enhances its resistance to harsh environments. This belt type is widely used in various industries, such as food processing, pharmaceuticals, and marine applications. Its ability to withstand extreme conditions makes it a reliable choice.

One of the key benefits of the 316L stainless steel belt is its strength. It can handle heavy loads and maintain its structural integrity over time. Moreover, its smooth surface prevents the accumulation of bacteria, making it suitable for sanitary environments. However, it can be more costly than other materials, which may lead some to hesitate.

Another advantage is its aesthetic appeal. The shiny finish is visually attractive, drawing attention in any application. While it is low maintenance, scratches can affect the appearance, requiring some care. Thoughtful use and proper installation can prevent these issues, but not everyone may be aware of this. Thus, understanding the challenges is crucial for maximizing the advantages of 316L stainless steel belts.

| Property | Details |

|---|---|

| Material Type | 316L Stainless Steel |

| Corrosion Resistance | Excellent resistance to chlorides and harsh environments. |

| Mechanical Strength | High tensile strength and good ductility at varying temperatures. |

| Applications | Used in chemical processing, marine applications, and medical devices. |

| Manufacturing Process | Cold rolling or welding, ensuring high precision and efficiency. |

| Temperature Resistance | Retains strength and stability at elevated temperatures. |

| Maintenance | Easy to clean and maintain, typically only requires soap and water. |

316L stainless steel is a low-carbon version of 316 stainless steel. It contains 16% chromium, 10% nickel, and 2% molybdenum. This unique composition enhances its corrosion resistance. The lower carbon content minimizes carbide precipitation, making it ideal for high-temperature applications.

One significant benefit of 316L stainless steel is its resistance to pitting in chloride environments. It's durable and often used in chemical processing. According to the International Stainless Steel Forum, 316L has a pitting resistance equivalent to a PREN (Pitting Resistance Equivalent Number) of about 24. This feature is crucial for marine and coastal applications.

Moreover, this alloy exhibits good weldability and can be easily fabricated. It has a tensile strength of approximately 70,000 psi and a yield strength of about 30,000 psi. However, it is not entirely immune to stress corrosion cracking. In some cases, improper processing can lead to unexpected failures. Understanding these properties aids in selecting the right material for specific contexts.

316L stainless steel belts are highly valued for their durability and resistance to corrosion. These belts are used across various industries due to their impressive properties. Common applications include the food processing, pharmaceutical, and chemical sectors. In food processing, for instance, their resistance to various substances ensures hygiene and safety. According to industry reports, 316L stainless steel is particularly effective in high-temperature environments, maintaining structural integrity where others fail.

In pharmaceutical applications, these belts serve critical roles in manufacturing environments. They help maintain sterile conditions, ensuring that no contaminants affect product quality. Additionally, the chemical processing industry relies heavily on 316L stainless steel. This material can withstand harsh chemicals and extreme conditions, reducing the risk of equipment failure.

**Tip:** When selecting a stainless steel belt, consider the environment in which it will be used. Each application may demand specific features. Features like surface finish can make a significant difference in performance.

User feedback shows that while 316L belts are reliable, they require regular maintenance. A proper maintenance routine can enhance their longevity and functionality. Ignoring small details may lead to bigger issues down the road, affecting productivity.

316L stainless steel belts are renowned for their exceptional properties. They offer high resistance to corrosion, making them suitable for various industries. According to industry reports, the use of 316L stainless steel has increased by 15% annually due to its durability and performance.

One significant advantage of 316L stainless steel belts is their ability to withstand harsh environments. They are often used in chemical processing and marine applications. These belts can resist pitting and crevice corrosion in chloride environments. However, challenges remain. In some cases, they may not withstand hydrogen embrittlement in specific conditions.

Additionally, 316L stainless steel belts are easy to clean and maintain. This feature is crucial in the food processing and pharmaceutical sectors. Regular maintenance can enhance their lifespan. Nevertheless, some users report difficulty in sourcing high-quality belts. This can lead to potential failures that affect production efficiency. Overall, the benefits are evident, but users must remain vigilant.

316L stainless steel belts are known for their durability and corrosion resistance. To maintain their quality, regular care is essential. Start by cleaning the belts with mild soap and water. Avoid harsh chemicals, as they may damage the surface finish. Use a soft cloth or sponge for gentle cleaning. This practice prolongs the life of the belts, ensuring they remain functional for years.

In industrial settings, a study by the International Journal of Materials Science found that proper maintenance can enhance the lifespan of stainless steel components by up to 30%. Adjusting tension and alignment is crucial too. Misalignments can cause uneven wear. Regular inspections can catch these issues early.

Moisture can lead to corrosion, even in stainless steel. Therefore, after cleaning, wipe down the belts and store them in a dry environment. This small step makes a significant difference. Neglecting maintenance can result in costly replacements. Many technicians overlook these details, leading to premature failures.