Leave Your Message

The 316l Stainless Steel Pipe is a popular choice in various industries. Known for its durability, this pipe offers excellent resistance to corrosion. It is often used in environments where exposure to harsh chemicals is common.

One key benefit of the 316l Stainless Steel Pipe is its high strength. Even at elevated temperatures, it maintains its structural integrity. This makes it suitable for both industrial and residential applications. Think about its use in marine environments. Here, the pipe stands up to saltwater corrosion, proving its reliability.

However, not all users are aware of its maintenance needs. Regular checks are essential to avoid pitting or crevice corrosion. The cost can also be a concern for some. While the initial investment is higher, the long-term benefits often outweigh this disadvantage. In considering 316l Stainless Steel Pipes, one must weigh these aspects carefully.

316L stainless steel pipe is a popular choice in various industries. This material contains a low carbon content, which enhances its resistance to corrosion. It's particularly useful in environments where exposure to harsh chemicals is common.

The unique composition of 316L stainless steel includes molybdenum. This addition strengthens the material further, offering superior protection against pitting and crevice corrosion. Applications range from construction to medical devices. In fact, you might find it in pipelines, tanks, and even architectural structures.

However, it isn't without its drawbacks. The manufacturing process can be energy-intensive. Additionally, while it is durable, the cost can be higher compared to other materials. This raises questions about cost-effectiveness in certain projects. Users often weigh performance against budget constraints, leading to important discussions on material selection.

316L stainless steel is a popular material known for its exceptional corrosion resistance. It primarily contains 16% chromium and 10% nickel, with a low carbon content around 0.03%. This unique composition enhances its resistance to pitting and crevice corrosion. Studies indicate that it performs well even in harsh environments like chloride exposure, making it suitable for marine applications.

The mechanical properties of 316L stainless steel are notable. It exhibits a tensile strength of approximately 70,000 psi and yield strength of about 30,000 psi. This strength ensures durability, even when subjected to high stress. Yet, its ability to undergo welding without losing strength adds to its versatility in construction and manufacturing. However, one must consider that the stainless steel can still be susceptible to extreme temperatures, requiring cautious handling.

Notably, 316L’s resistance to oxidation is impressive. Such features make it a favorable choice in chemical processing industries. Yet, there are challenges. Its cost might be a concern for some businesses, and over time, it can still develop surface stains if not maintained properly. Balancing these factors is crucial for effective use in various applications.

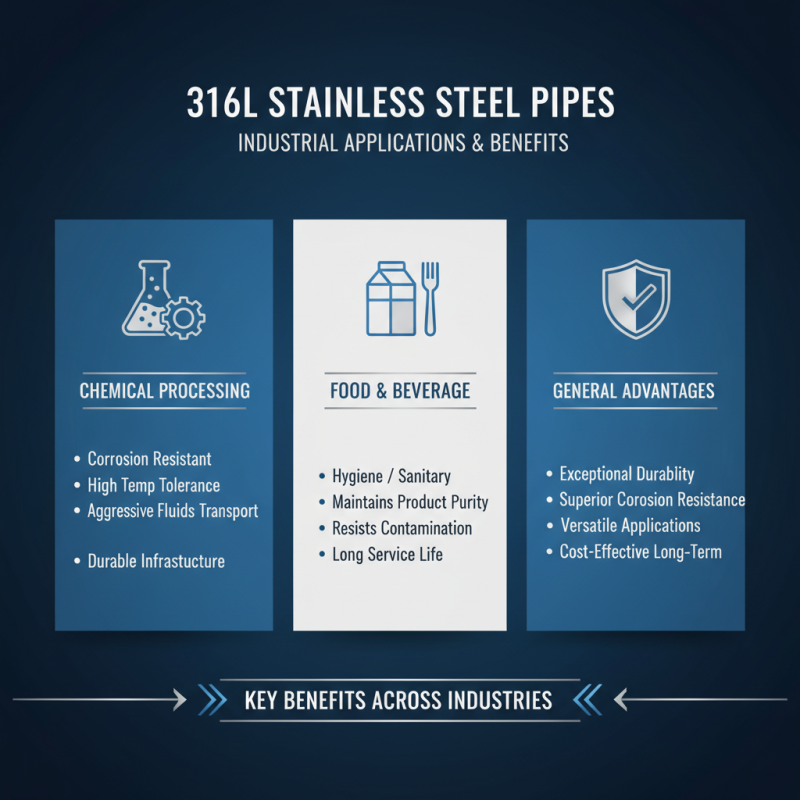

316L stainless steel pipes are widely used across various industries due to their exceptional durability and resistance to corrosion. In the chemical processing industry, these pipes are essential for transporting aggressive fluids. Their ability to withstand high temperatures and harsh chemicals makes them ideal for such applications. In the food and beverage sector, 316L stainless steel is favored for its hygiene properties and ability to maintain quality.

In the construction industry, these pipes provide structural integrity while resisting rust. They are used in handrails, balconies, and other architectural features. The marine industry also benefits, as 316L stainless steel does not easily corrode in saltwater. This quality extends the lifespan of equipment and infrastructure in coastal areas.

Tips: Ensure proper installation. A small mistake can lead to leaks or failures. Regular maintenance checks are crucial for longevity. Don’t overlook early signs of wear. Even 316L can have vulnerabilities if not monitored. Choose certified fabricators. Quality can vary, and it’s critical for safety.

316L stainless steel pipe is known for its excellent resistance to corrosion and durability. It is widely used in various industries, such as chemical processing, maritime applications, and food production. One major advantage of 316L pipes is their ability to withstand harsh environments. The low carbon content helps to minimize carbide precipitation, which can occur during welding.

Consider the ease of installation when choosing 316L stainless steel pipes. They are lightweight and can be easily cut to size. This feature can save labor time and costs. Additionally, the smooth surface of these pipes ensures efficient flow characteristics. They decrease friction, which is beneficial in fluid transport applications.

Tip: Always check compatibility with the fluids handled. While 316L is versatile, some chemicals can react unexpectedly. Don’t skip this step.

One should also be aware of potential drawbacks. 316L pipes might be more expensive compared to standard stainless steel options. Budget considerations are essential. Investing in these pipes may provide long-term savings due to reduced maintenance and replacement needs.

Maintaining 316L stainless steel pipelines requires careful attention. Regular inspections are vital. Check for signs of corrosion or pitting. The environment plays a significant role. In coastal areas, salt exposure can lead to unexpected issues. Reports show that up to 20% of stainless steel installations face early degradation without proper maintenance.

Cleaning practices can enhance the longevity of these pipelines. Use mild detergents and soft cloths for surface cleaning. Avoid abrasive materials that might scratch the surface. It’s advised to create a routine maintenance schedule. Cleaning every six months is a good baseline. For environments with more harsh conditions, more frequent checks are necessary.

Pay attention to joint connections, as they can be weak points. Loose fittings may lead to leaks. Regular tightening and checking can mitigate risks. Ultimately, understanding the specific needs of 316L stainless steel is crucial. Each installation presents unique challenges. Continuous learning and adaptation are necessary to ensure optimal performance and durability.