Leave Your Message

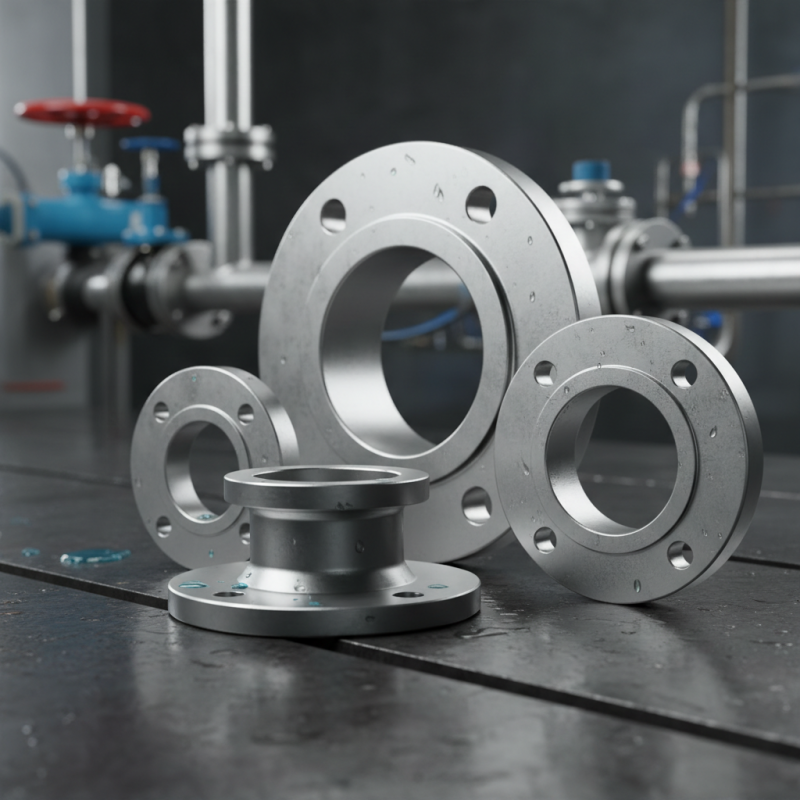

In the world of industrial applications, 316L stainless steel flanges stand out as a reliable choice. Expert John Smith, a renowned materials engineer, once said, "Choosing the right flange material can make or break a project." This statement highlights the importance of understanding the benefits of 316L stainless steel flanges.

316L stainless steel flanges offer remarkable corrosion resistance, making them suitable for challenging environments. Projects involving chemicals or saltwater can greatly benefit from this material. Furthermore, the strength of 316L allows for durability under pressure. Clients often appreciate these factors, yet some may overlook the cost-effectiveness associated with long-term performance.

While the advantages are numerous, it's essential to consider the complexities that come with using 316L stainless steel flanges. Not all applications may require such high-grade material. It's crucial to evaluate specific project needs carefully. In the end, informed decisions lead to better outcomes and can enhance project success.

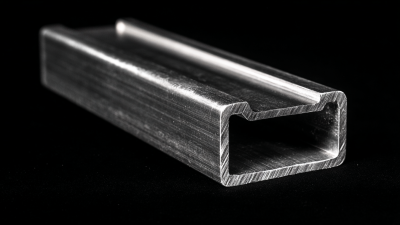

316L stainless steel flanges are widely used in various industries due to their unique properties. These flanges contain molybdenum, which enhances their resistance to corrosion. They work well in environments with high levels of chloride, such as marine applications. The durability and strength of 316L make it suitable for piping systems, oil and gas, and chemical processing.

In construction and manufacturing, 316L stainless steel flanges are often favored. Their high tensile strength ensures that they can withstand extreme pressures. Many designers appreciate the ease of installation. However, some might question the cost-effectiveness in large projects. The initial investment can be significant. Yet, the longevity of these flanges can lead to lower maintenance costs over time.

Not all projects may require 316L stainless steel flanges. For example, less demanding applications might benefit from other materials. It's essential to assess the specific needs of each project carefully. Balancing budget constraints with material properties can be challenging. Each choice comes with its own set of advantages and drawbacks. It's important to reflect on the overall requirements before making a decision.

316L stainless steel flanges are renowned for their outstanding corrosion resistance. This feature is vital for industries such as chemical processing and oil and gas. According to a study by the International Stainless Steel Forum, 316L has a pitting resistance equivalent number (PREN) that often exceeds 20. This allows it to withstand harsh environments like saltwater and acidic solutions.

The durability of 316L is remarkable. It offers resistance to localized corrosion, such as pitting and crevice corrosion. Such protection is crucial for equipment longevity. In marine applications, for example, flanges material made of 316L can remain intact for decades, even in corrosive marine environments. A corrosion rate of less than 0.1 mm per year in seawater is often cited, proving its efficacy.

However, the resistance isn't absolute. Under severe conditions or improper maintenance, even 316L may suffer from stress corrosion cracking. Thus, regular monitoring is essential. While its advantages are significant, engineers must weigh potential challenges. The initial cost is higher than carbon steel options. Yet, the long-term savings from reduced maintenance and replacement can justify the investment.

When it comes to strength and durability, 316L stainless steel flanges stand out. This material offers excellent resistance to corrosion, making it ideal for demanding environments. Whether in chemical processing or marine applications, these flanges maintain their integrity while withstanding harsh conditions. The low carbon content reduces the risk of carbide precipitation, which enhances longevity and reliability.

However, 316L flanges are not without their limitations. They can be more expensive than other materials, which can strain budgets for some projects. Additionally, while they resist many forms of corrosion, they are not immune to pitting under certain conditions. Attention to installation and maintenance is essential to ensure they perform as expected. Choosing the right flange requires careful consideration of all project parameters. Ultimately, the benefits of using 316L flanges often outweigh the potential drawbacks, making them a trusted choice in many industries.

| Benefit | Description |

|---|---|

| Corrosion Resistance | 316L flanges provide excellent resistance to pitting and crevice corrosion in chloride environments. |

| High-Temperature Resistance | They maintain strength and structural integrity at elevated temperatures. |

| Durability | Designed for longevity, minimizing the need for frequent replacements. |

| Versatility | Suitable for various applications, including chemical processing, petrochemical, and marine environments. |

| Cost-Effective | Lower maintenance costs due to their durability and corrosion resistance. |

| Ease of Fabrication | 316L flanges are easier to work with, allowing for complex designs. |

| Hygienic Properties | Ideal for food and beverage applications where cleanliness is paramount. |

| Low Magnetic Susceptibility | Minimizes interference in sensitive applications like electronics or medical devices. |

| Aesthetic Appeal | The polished finish provides a sleek look, enhancing project aesthetics. |

When it comes to 316L stainless steel flanges, versatility in design is a significant advantage. These flanges can be customized to meet specific project needs. Whether you require special dimensions or unique shapes, customization options are plentiful. This flexibility allows designers and engineers to create systems that fit perfectly, even in constrained spaces.

Adapting flanges to different applications can be crucial, yet it isn’t always straightforward. Some designs may require extensive analysis to ensure they fulfill their intended purpose. The balance between aesthetics and functionality can create challenges. However, when done right, customized flanges enhance system performance significantly.

Furthermore, the ability to choose different finish options offers additional possibilities. Polished surfaces can be visually striking. Meanwhile, matte finishes can prioritize functionality over looks. Each decision shapes the final product, leading to a unique result. Yet, it’s essential to consider the potential drawbacks of customization. Sometimes, intricate designs can complicate manufacturing and lead to delays. Balancing customization with practicality is key to achieving successful outcomes.

When it comes to choosing materials for your projects,

316L stainless steel flanges stand out due to their

cost-effectiveness.

Although the initial investment may seem high, the long-term savings are significant.

This alloy offers excellent resistance to corrosion and oxidation.

Therefore, it requires less maintenance over time, which saves money in the long run.

Many projects fail to realize these hidden costs, leading to

overspending.

Durability is another advantage.

316L flanges are robust and can handle extreme conditions.

This guarantees a longer lifespan for your installations.

However, some users overlook the importance of

proper installation techniques. Even the best materials can fail without

correct handling. An inexperienced team may create

issues that could have been avoided.

Furthermore, 316L stainless steel flanges are versatile.

They can be used in various industries, from food processing to petrochemicals.

This adaptability can also lead to cost savings, as fewer materials

need to be sourced. Yet, it’s crucial to evaluate specific project needs first.

Misjudging the application can lead to unsuitable material choices.

Such decisions can impact long-term performance and expenses.