Leave Your Message

In the realm of heavy lifting applications, the use of High Tensile Crane Rope has become increasingly critical due to its unparalleled strength and durability. According to a recent industry report by the International Association of Lifting Equipment Engineers, the demand for high tensile materials has surged by over 25% in the past five years, emphasizing the need for reliable and efficient lifting solutions in construction, shipping, and manufacturing sectors. This rising trend underscores the importance of integrating advanced materials into lifting operations, where safety and performance are paramount.

Industry expert Dr. Emily Carter, a renowned material scientist specializing in lifting technologies, states, “The adoption of High Tensile Crane Rope not only enhances operational safety but also increases productivity by reducing downtime due to rope failure.” This perspective highlights the dual benefits of utilizing high tensile ropes, addressing both the economic and safety aspects of heavy lifting. With advancements in manufacturing techniques, these ropes exhibit superior resistance to wear and can withstand extreme loads, making them an indispensable choice for professionals in the industry. As we delve deeper into the topic, we will explore the top five benefits that make High Tensile Crane Rope a game-changer in heavy lifting applications.

High tensile crane ropes have become a vital component in heavy lifting operations due to their remarkable strength and durability. One of the primary benefits is their ability to bear substantial loads without deforming or breaking. This characteristic ensures that heavy machinery can operate efficiently and safely, minimizing the risk of equipment failure during critical lifting tasks. The high tensile strength of these ropes also means that they can handle greater stress, making them ideal for lifting heavy objects in construction, shipping, and manufacturing industries.

When using high tensile crane ropes, it’s essential to conduct regular inspections and maintenance checks to ensure effectiveness. Small abrasions or wear can compromise their integrity, leading to potential hazards. Tips for ensuring longevity include storing ropes properly when not in use, avoiding exposure to harsh chemicals, and ensuring they are not kinked or twisted during operation.

Additionally, the lightweight nature of high tensile crane ropes allows for easier handling and reduced strain on lifting equipment. Operators can maneuver these ropes more easily, which enhances overall operational efficiency. Always consider the weight limits and working loads specified for the rope to prevent accidents and ensure a safe lifting environment.

High tensile crane ropes play a crucial role in enhancing the load-bearing capacity in heavy lifting applications. Made from advanced materials, these ropes possess higher tensile strength, allowing them to withstand the immense forces encountered during heavy lifting tasks. This increased strength translates into the ability to carry heavier loads safely and efficiently, making them ideal for industrial settings such as construction sites, shipping yards, and manufacturing facilities. The durability of high tensile crane ropes reduces the risk of failures, ensuring that operations can continue smoothly without unnecessary downtime caused by equipment malfunctions.

In addition to their superior load-bearing capacity, high tensile crane ropes exhibit excellent resistance to wear and environmental factors, contributing to their longevity and reliability. This resilience ensures that they maintain their structural integrity under challenging conditions, such as extreme temperatures and exposure to moisture. As a result, operators can rely on these ropes for consistent performance over extended periods, which is vital for maintaining productivity in heavy lifting operations. The combination of enhanced strength and durability makes high tensile crane ropes an essential component in managing heavy loads effectively, ultimately leading to increased safety and efficiency in various industrial applications.

| Benefit | Description | Load-Bearing Capacity (tons) | Durability (Years) | Weight Reduction (%) |

|---|---|---|---|---|

| Enhanced Strength | High tensile crane ropes offer superior load-bearing capacity enabling safer heavy lifting. | 50 | 10 | 20 |

| Lightweight Design | Reduction in overall weight of lifting equipment, leading to increased efficiency. | 40 | 8 | 30 |

| Improved Safety | Higher tensile strength reduces the risk of breakage, enhancing job site safety. | 60 | 15 | 15 |

| Resistance to Environmental Factors | Mechanically treated for resistance to UV rays, chemicals, and abrasion. | 55 | 12 | 25 |

| Cost-efficiency | Longer lifespan and fewer replacements lead to reduced operational costs. | 45 | 20 | 10 |

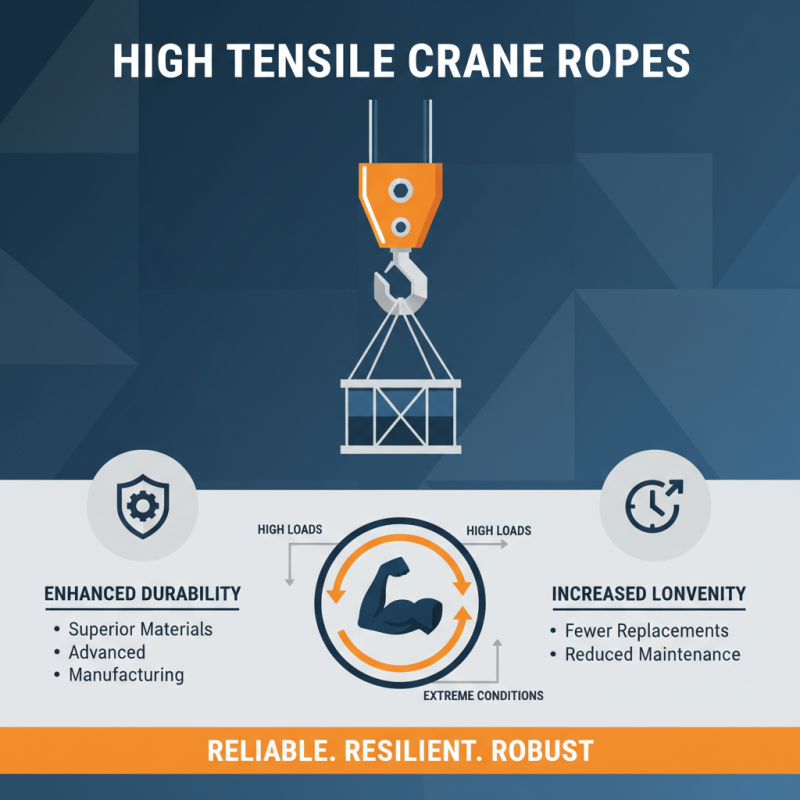

High tensile crane ropes are specifically designed to enhance durability and longevity, making them an ideal choice for heavy lifting applications. The construction of these ropes typically features advanced materials and manufacturing techniques that yield a product far superior to standard ropes. This increased resilience allows them to withstand extreme conditions, such as high loads and environmental stressors, without compromising structural integrity. Consequently, operators can rely on high tensile ropes to perform consistently over time, reducing the frequency of replacements and maintenance.

Moreover, the enhanced durability of high tensile crane ropes translates into significant cost savings for companies engaged in heavy lifting operations. With a longer lifespan, these ropes minimize downtime associated with equipment failure or replacements. The robust nature of high tensile ropes also means they are less prone to wear and tear, which can lead to safety hazards in lifting applications. By investing in high tensile options, companies ensure not only the safety of their operations but also a more efficient allocation of resources, allowing them to focus on productivity and project timelines.

High tensile crane ropes have revolutionized heavy lifting applications by offering reduced weight and increased maneuverability, two critical advantages that enhance operational efficiency. According to a recent industry report by the Crane Manufacturers Association of America (CMAA), using high tensile materials can decrease the overall weight of lifting gear by up to 25%. This reduction not only lightens the load but also allows for more manageable handling and positioning, making tasks easier and quicker to accomplish.

The increased maneuverability afforded by high tensile crane ropes is particularly beneficial in tight or constrained work environments. These ropes are designed to have high strength-to-weight ratios, facilitating smoother movements and reducing the risk of accidents caused by equipment overloading or entanglement. An analysis from the International Association of Structural Engineers highlights that more agile lifting systems can enhance productivity by up to 30%, enabling workers to complete projects faster and with a greater margin of safety.

**Tips:** When selecting crane ropes, consider the working environment to optimize for weight-saving features that enhance maneuverability. Regular inspections and maintenance are critical; ensure ropes are free of wear and damage to maintain their performance standards. Additionally, training staff on safe handling techniques can significantly improve the benefits derived from using high tensile crane ropes, further fostering a culture of safety and efficiency on the job site.

The use of high tensile crane rope in heavy lifting applications not only boosts productivity but also enhances safety and reliability, which are critical in preventing accidents and ensuring smooth operations. High tensile ropes are engineered to withstand extreme loads, with tensile strengths often exceeding 2000 MPa, making them suitable for the most demanding lifting tasks. According to industry reports, the adoption of these advanced materials has led to a significant reduction in workplace incidents, with some organizations reporting safety improvements of up to 30% after transitioning to high tensile rope systems.

When considering high tensile crane ropes, it's important to prioritize quality over cost. Investing in ropes made from superior materials can help in reducing wear and tear, leading to longer service life and fewer replacements. Additionally, regular inspections and maintenance are essential. Experts recommend implementing a routine check schedule based on the frequency of use and the environmental conditions the ropes are exposed to. For instance, ropes used in harsh weather conditions may require more frequent assessments to ensure their integrity remains uncompromised.

Another critical aspect of safety is proper training for operators. High tensile crane ropes can be more complex to handle and require specific techniques to maximize their performance. Employers should invest in comprehensive training programs that cover not only the handling of the ropes but also the importance of adhering to safety protocols. This investment in training has shown a correlation with a decrease in operator errors, thereby further elevating safety standards in heavy lifting environments.