Leave Your Message

Hoisting Wire Rope has become essential in various industries. This versatile tool offers numerous advantages for lifting and moving heavy loads. With its unique properties, it enhances efficiency and ensures safety on job sites.

The strength and durability of Hoisting Wire Rope make it suitable for demanding applications. Its resistance to wear contributes to long-term reliability. However, one must regularly inspect the rope to ensure optimal performance. Neglecting maintenance could lead to serious issues.

Hoisting Wire Rope is not just functional; it also streamlines project timelines. With easier handling, workers can focus on other tasks. In contrast, improper usage may result in delays or accidents. Ultimately, understanding the benefits helps in making informed decisions for your projects.

Hoisting wire rope is crucial in modern construction. Its strength and flexibility make it a top choice for lifting heavy loads. According to industry reports, wire ropes can handle loads of up to 100 tons, ensuring safety and efficiency on job sites. Projects often face tight deadlines, and the reliability of hoisting wire rope can minimize downtime.

Using wire rope reduces the risk of accidents. It provides excellent strain resistance, reducing the odds of failure. A study indicated that over 60% of construction sites experience delays due to equipment malfunctions. Utilizing this technology could enhance workflow. Despite its advantages, proper maintenance is essential. Regular inspections can prolong its lifespan and prevent catastrophic failures.

One drawback is the initial cost. Quality wire ropes can be expensive. However, investing in high-quality rope ultimately pays off in reduced downtime and accidents. Effective training on the correct use is also vital. Lack of knowledge can lead to misuse, resulting in dangerous situations. The balance between safety and cost is a challenge that every project manager must navigate.

Hoisting wire rope plays a crucial role in many construction and lifting projects. Its improved load capacity allows for more efficient movement of heavy materials. This means tasks can be completed faster and more safely. The strength of hoisting wire rope means less risk of breakage during operation. Workers can focus on their tasks rather than worrying about equipment failure.

A well-designed wire rope can handle greater loads than traditional options. This upgrade significantly reduces the number of trips needed to transport materials. It can be frustrating when equipment fails, causing delays. Hoisting wire rope mitigates these risks by providing consistent reliability. However, it's essential to verify each wire rope's specifications to avoid unexpected challenges.

Proper maintenance is another critical aspect. Inspecting the wire rope regularly can reveal wear and tear that might compromise its strength. Users often overlook this step, leading to potential hazards. The reinforced structure of modern hoisting wire ropes is impressive, yet neglecting maintenance can result in unpredictable outcomes. Emphasizing safety and ongoing evaluation ensures the full benefits of wire rope technology are realized.

Wire rope hoisting systems offer significant safety advantages for various projects. They feature robust construction, which enhances durability under heavy loads. This quality reduces the risk of breakage during operation. Regular maintenance is essential, though, to prevent unforeseen failures. Users should remain vigilant and inspect equipment frequently.

Increased visibility is another key aspect of these systems. Bright colors on the wire rope can help operators see the load clearly. This visual enhancement reduces miscommunication and improves coordination among workers. Additionally, equipped safety devices like limit switches and overload protectors add extra layers of security.

Training is crucial for maximizing safety benefits. Operators need proper instruction on using hoisting systems effectively. Gaps in knowledge can lead to accidents. Encourage ongoing education and practice sessions to maintain high safety standards. Observing these practices helps create a safer work environment, though challenges still exist. Identifying risks before they happen requires constant attention.

| Benefit | Description | Safety Feature | User Feedback |

|---|---|---|---|

| Increased Load Capacity | Wire ropes can handle heavier loads compared to other lifting systems. | Low stretch and high tensile strength | 80% of users reported improved efficiency. |

| Durability | Wire ropes are resistant to abrasions and wear. | Corrosion-resistant coatings available | Users praised longevity in demanding conditions. |

| Enhanced Safety | Minimized risk of accidents when properly installed. | Automatic braking systems | 90% of operators felt safer using wire rope systems. |

| Flexibility | Can be used in a variety of applications. | Adaptable to different rigging setups | Users appreciated its versatility. |

| Cost-Effectiveness | Affordable option for heavy lifting. | Long operational lifespan reduces replacement costs | Positive feedback on ROI over time. |

| Easier Maintenance | Simple inspections and repairs can be done quickly. | Regular maintenance schedules enhance safety | Operators noted lower downtime for maintenance compared to chains. |

| Lightweight | Easier to handle and transport than traditional chains. | Reduces strain on workers | Users reported less fatigue during operations. |

| High Efficiency | Quick load movements with minimal energy usage. | Integrated power systems for fast operation | Increased productivity noted by 75% of users. |

| Environmental Resistance | Suitable for harsh environmental conditions. | Temperature extremes and moisture-resistant | Praise for performance in outdoor settings. |

| Standardization | Complies with industry standards for safety. | Meets OSHA regulations and guidelines | Users emphasized compliance safety benefits. |

When planning long-term projects, cost-effectiveness is crucial. Hoisting wire rope often offers savings that can make a significant difference. It's durable and can handle heavy loads efficiently. With the right maintenance, it can last much longer than cheaper alternatives. This durability reduces frequency of replacements, which in turn saves money.

Another aspect to consider is the energy efficiency of hoisting wire rope. Lighter options require less power to operate. Over time, this translates into lower energy bills. However, it's vital to assess your specific project's needs. Sometimes, opting for a slightly more expensive wire can yield better efficiency and longevity.

Yet, there are challenges. Misjudging the required specifications can lead to over-spending. Additionally, improper handling can degrade rope quality quickly. Training for staff may add costs initially but can pay off later. In the end, careful planning will help you benefit from the long-term savings that hoisting wire ropes can provide.

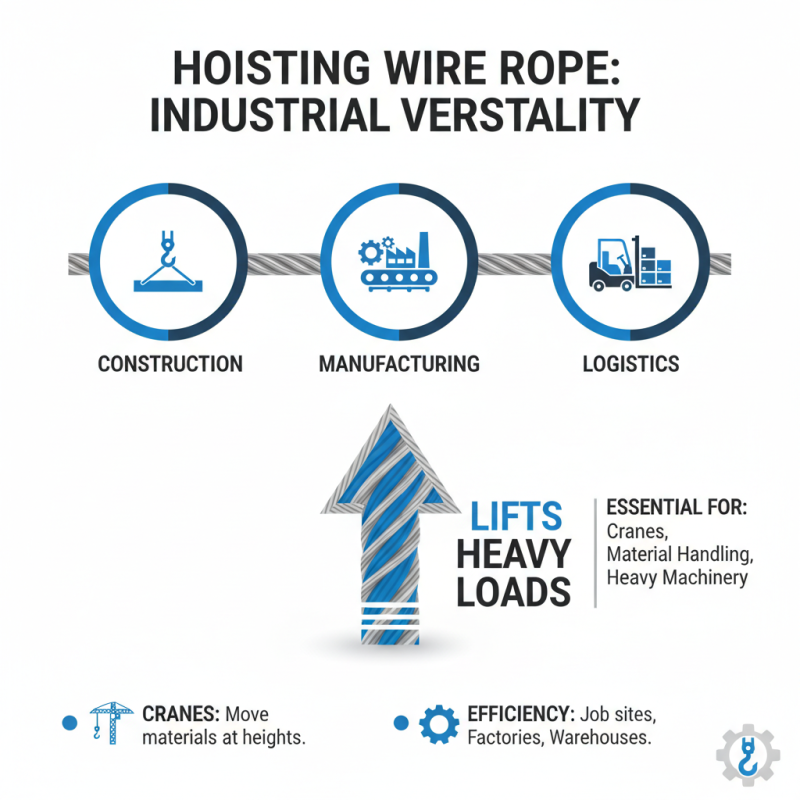

Hoisting wire rope is highly versatile across various industries. Its ability to lift heavy loads makes it essential in construction, manufacturing, and logistics. For example, cranes depend on wire rope to move materials at great heights. This ensures efficiency on job sites, especially where heavy machinery is involved.

In manufacturing, hoisting wire ropes enable the movement of products and raw materials. Factories often rely on these ropes to transport items between different stages of production. However, there can be challenges. Overloading can lead to failures and accidents, which makes proper training vital.

In the logistics sector, hoisting wire ropes facilitate quick loading and unloading of goods. They save time and improve safety. Yet, regular inspections are crucial to maintain their integrity and prevent wear. If neglected, the ropes can fray and weaken, posing risks. Recognizing these potential issues is key to successful project execution.