Leave Your Message

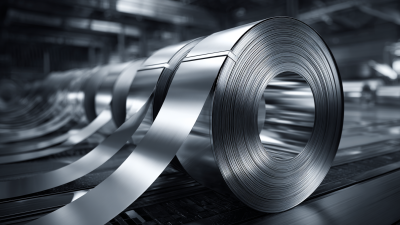

The rise of 316L stainless steel belts in various industries marks a significant advancement in materials engineering, driven by their unique properties and application versatility. Unlike standard stainless steel, 316L offers improved corrosion resistance, particularly in harsh environments where exposure to chloride solutions is prevalent. According to a report by the International Stainless Steel Forum, the demand for corrosion-resistant materials has increased by over 25% in sectors such as food processing, pharmaceuticals, and petrochemicals, highlighting the importance of materials like the 316L stainless steel belt.

Furthermore, the mechanical strength and durability of 316L stainless steel belts make them an ideal choice for industries that require high-performance materials capable of withstanding extreme conditions. Research from the Materials Research Society indicates that the global market for stainless steel products is projected to reach $150 billion by 2025, with 316L grades gaining substantial market share due to their reliability and longevity. This shift underscores the pivotal role that 316L stainless steel belts play in not only enhancing operational efficiency but also reducing maintenance costs across various applications, thereby solidifying their status as a staple in modern industrial practices.

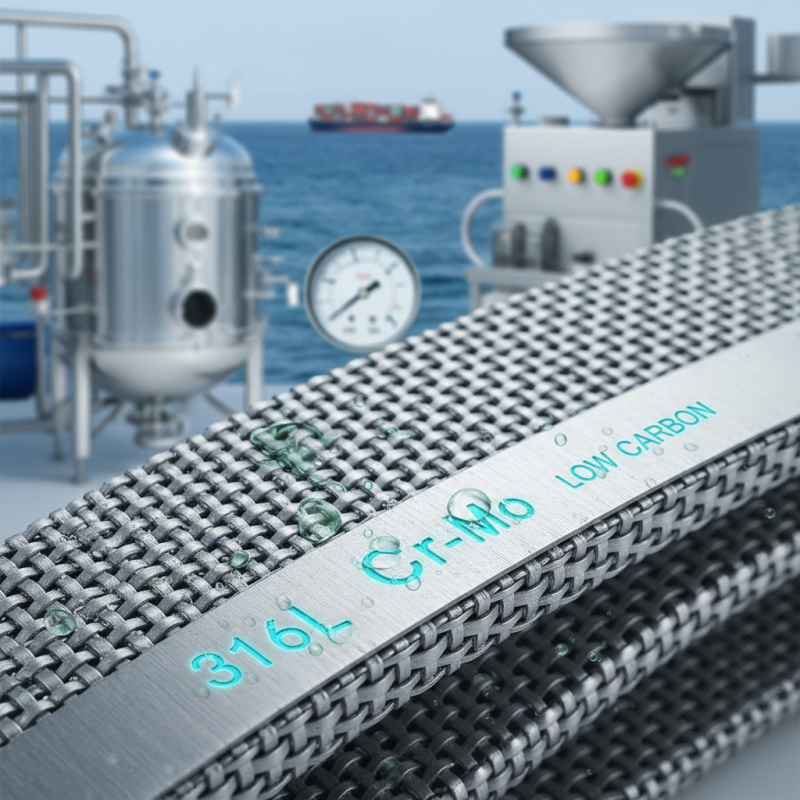

316L stainless steel belts offer exceptional corrosion resistance, making them an ideal choice in various industries including food processing, pharmaceuticals, and chemical manufacturing. The low carbon content of 316L enhances its resistance to stress corrosion cracking and pitting, allowing it to perform reliably even in harsh environments. This durability significantly reduces maintenance costs and downtime, ensuring that operations can proceed without interruptions caused by belt failures.

When implementing 316L stainless steel belts in your operations, consider that their resistance to corrosive substances extends the lifespan of the belts significantly. It's crucial to regularly inspect the belts for signs of wear and tear, as external factors like temperature and exposure to chemicals can impact performance. By maintaining a routine inspection schedule, businesses can anticipate potential issues before they lead to costly repairs or replacements.

For optimal performance, ensure that the belts are adequately lubricated and kept free from contaminants. This will not only enhance their resistance to corrosion but also promote smoother operation and energy efficiency. Additionally, consider the environmental conditions in which the belts will be used, as certain temperatures and chemical exposures may require specific considerations to maximize their effectiveness and lifespan.

316L stainless steel has gained prominence in various industries due to its superior durability and longevity. This material is known for its remarkable resistance to corrosion, which is essential in environments where exposure to harsh chemicals and saltwater is common. According to industry studies, 316L stainless steel belts can withstand corrosive materials at temperatures up to 800°F, making them ideal for applications in marine, chemical, and food processing sectors. The low carbon content of 316L also contributes to its stability, reducing the risk of carbide precipitation and enhancing its performance in high-temperature environments.

When considering the implementation of 316L stainless steel belts, industries should be aware of the significant long-term cost savings associated with their use. While the initial investment may be higher compared to other materials, the extended lifespan and reduced maintenance requirements often result in lower operational costs over time. Additionally, various studies have shown that equipment utilizing 316L stainless steel belts exhibit a decrease in wear and tear, translating into fewer replacements and downtime, crucial for maintaining productivity.

Tips: To maximize the longevity of 316L stainless steel belts, ensure regular inspections and maintenance are performed. Cleaning with non-abrasive agents and avoiding exposure to chlorine chemicals will further extend their service life. Additionally, consider integrating 316L stainless steel belts in applications where other materials have historically failed, such as in food processing conveyors, to take advantage of its unique properties.

316L stainless steel belts are increasingly recognized for their versatility across various industries, primarily due to their exceptional corrosion resistance and mechanical properties. In the pharmaceutical and food processing sectors, where hygiene and compliance with stringent regulations are paramount, 316L stainless steel’s ability to withstand harsh cleaning agents and high temperatures makes it an ideal material. According to a report from the International Stainless Steel Forum, the use of stainless steel in the food and beverage industry has grown by 5% annually, reflecting its importance in maintaining product integrity and safety.

Moreover, the chemical processing industry has seen significant advancements with the incorporation of 316L stainless steel belts in conveyor systems. These belts can endure chlorine, sulfuric acid, and other aggressive substances, reducing wear and tear and consequently lowering replacement costs. Data from a recent market analysis highlights that investments in corrosion-resistant materials are expected to increase by 7% in this sector over the next five years, indicating a shift towards durable solutions that enhance operational efficiency. This trend is further fueled by the increasing demand for sustainable practices, as 316L stainless steel is fully recyclable and contributes to reduced environmental impact.

The use of 316L stainless steel belts in various industries significantly enhances hygiene and safety standards. One of the key advantages of 316L stainless steel is its resistance to corrosion and pitting, which is crucial in environments where sanitation is paramount, such as food processing and pharmaceuticals. According to a report by the International Journal of Food Microbiology, surfaces that resist contamination and can be easily cleaned contribute to lower levels of microbial growth, directly impacting the overall cleanliness of the production environment. This is particularly vital as industries strive to meet stringent hygiene regulations and standards, which often dictate the materials permissible in their operations.

Moreover, 316L stainless steel belts are designed to withstand harsh cleaning chemicals and high-temperature sterilization processes, making them ideal for applications that demand high levels of cleanliness. The European Hygienic Engineering & Design Group notes that equipment materials must not only be durable but also non-reactive with food substances to prevent contamination. The ability of 316L stainless steel to maintain its integrity under extreme conditions addresses this concern effectively, ensuring compliance with international safety standards.

Tips: When selecting materials for production facilities, consider the entire lifecycle of the equipment and its ease of maintenance. Regular monitoring and swift replacement of worn-out belts can prevent potential safety hazards. Investing in high-quality stainless steel solutions can reduce long-term costs associated with hygiene-related issues and equipment failures. Additionally, ensure that staff is adequately trained in maintaining and cleaning stainless steel to maximize its benefits.

The cost-effectiveness of 316L stainless steel belts stems from their durability and corrosion resistance, which significantly reduce long-term maintenance and replacement costs. According to industry reports, materials that minimize downtime and require less frequent replacement can lower operational expenses substantially. For instance, a study by the International Stainless Steel Forum (ISSF) indicates that stainless steel components can last up to 30% longer than other materials in corrosive environments, translating into significant savings when considering the total cost of ownership over time.

Moreover, the versatility of 316L stainless steel makes it suitable for a variety of applications across different industries, from food processing to petrochemicals. The ability to withstand extreme temperatures and aggressive chemicals without degradation further enhances its cost-effectiveness. In fact, a report by the American Society of Mechanical Engineers (ASME) indicates that using 316L stainless steel can decrease replacement frequencies by up to 40%, allowing companies to allocate resources more effectively. Not only does this increase productivity, but it also stabilizes budget forecasts, making 316L stainless steel belts a financially sound investment in the long run.