Leave Your Message

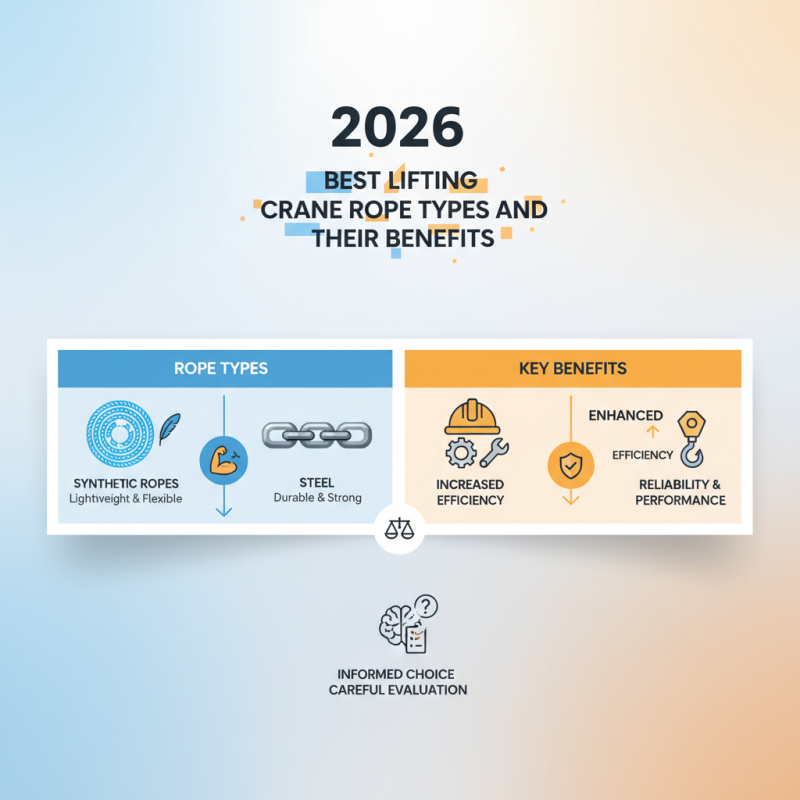

When selecting the right Lifting Crane Rope, knowing the types and their benefits is essential. Industry expert John Thompson stated, “The right rope can significantly enhance safety and efficiency.” This insight highlights the importance of making informed choices.

The choice of Lifting Crane Rope is influenced by several factors. Different tasks require different ropes, and understanding their characteristics is crucial. For instance, synthetic ropes are lightweight and flexible, yet they may lack the durability of steel ropes. Each option has strengths and drawbacks.

In an industry where safety is paramount, it is vital to reflect on the right choice. Dismissal of rope types can lead to accidents. Knowing the best Lifting Crane Rope ensures reliability and performance. We must weigh the options mindfully. Choices should be based on careful evaluation, not just on trends or cost.

In 2026, lifting crane operations rely on a variety of rope types, each with distinct features. Wire ropes are the most common. They consist of many strands twisted together. This construction provides strength and flexibility. Many construction sites prefer wire ropes for heavy loads. However, they can be prone to fraying and may require regular inspections.

Synthetic ropes, such as polyester and nylon, are gaining popularity. They are lightweight and easier to handle. These ropes resist UV damage and chemicals, making them suitable for diverse environments. However, their strength can diminish over time if exposed to the elements. It’s essential to monitor their condition closely.

Another emerging trend is the use of composite ropes. These innovative ropes combine the best of both worlds. They offer high strength while being lightweight. Yet, their cost can be a drawback. Many users find it challenging to weigh the initial investment against long-term benefits. Operators should evaluate various factors to determine the most effective option for their needs.

| Rope Type | Material | Load Capacity | Durability | Weight | Benefits |

|---|---|---|---|---|---|

| Wire Rope | Steel | Up to 200 tons | High | Heavy | Excellent tensile strength and fatigue resistance |

| Synthetic Rope | Nylon / Polyester | Up to 100 tons | Moderate | Lightweight | Resistant to abrasion and UV, floats on water |

| Chain Sling | Steel | Up to 300 tons | Very High | Heavy | Highly durable and secure for extreme loads |

| Braided Rope | Polyester | Up to 50 tons | Moderate | Lightweight | Flexible and easy to handle, good in wet conditions |

| High Modulus Polyethylene (HMPE) | Synthetic | Up to 150 tons | High | Very lightweight | High strength-to-weight ratio, excellent fatigue resistance |

When choosing between synthetic and steel crane ropes, it's important to consider performance characteristics. Synthetic ropes are lightweight. They are easier to handle and reduce operator fatigue. This can lead to increased efficiency on-site. However, synthetic materials may not have the same abrasion resistance as steel. This can be a concern in harsher environments.

On the other hand, steel crane ropes excel in strength and durability. They are less likely to stretch under heavy loads, making them ideal for high-stress operations. Rust and corrosion can be drawbacks, though. Regular maintenance is needed to prolong their lifespan. Operators must weigh these factors based on their lifting tasks.

Another consideration is safety. Synthetic ropes typically have a lower weight limit than steel. Knowing the load requirements is crucial. For some applications, the choice may seem obvious. Yet, it's essential to reflect on how conditions affect rope performance. Selecting the right type requires careful thought.

Kevlar ropes are revolutionizing the heavy lifting sector. Their lightweight nature is a game changer. According to a 2022 industry report, Kevlar's tensile strength is up to five times greater than steel. This offers significant advantages in demanding environments.

In projects involving cranes, work efficiency becomes critical. Kevlar ropes weigh much less than traditional options. This reduction in weight enables quicker setup and less strain on equipment. However, some users still question their durability. Kevlar performs well against abrasion but is sensitive to UV light. This requires careful consideration in outdoor applications.

Companies are seeing improved safety records. A study indicates that using Kevlar can reduce accidents by 30% compared to conventional ropes. Nevertheless, education on proper handling remains crucial. Many workers are unaware of the specific care needed for these advanced materials. Overall, the benefits of Kevlar start to shine through, yet caution is warranted.

This chart illustrates the various types of ropes used in heavy lifting applications and their key benefits. The data reflects the effectiveness, durability, and common applications of each rope type in the industry.

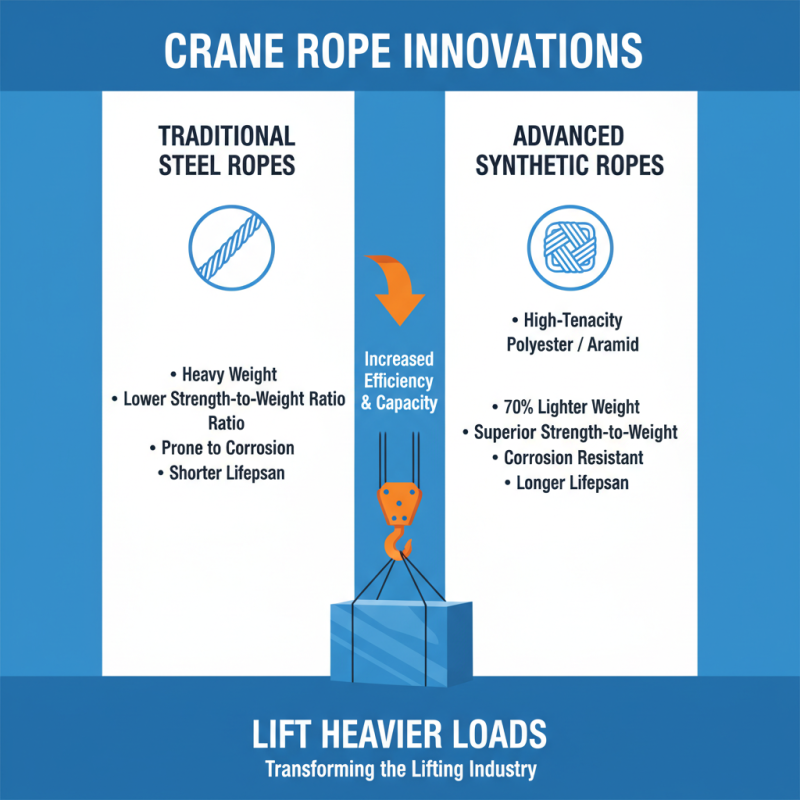

Innovations in crane rope materials are transforming the lifting industry. Advanced synthetic fibers, such as high-tenacity polyester and aramid, offer significant advantages over traditional steel ropes. These materials provide a stronger weight-to-strength ratio. For instance, the use of synthetic ropes can decrease overall weight by 70%. This allows cranes to lift heavier loads more efficiently.

Additionally, modern crane ropes are designed to resist abrasion and UV damage. Reports indicate that synthetic ropes can last up to three times longer than steel under similar conditions. They also minimize the risk of corrosion, a common issue with steel ropes. However, challenges remain. For example, synthetic ropes require careful handling to avoid damage. Their smooth surfaces lead to slip risks.

Users must also consider the impact of environmental conditions. Extreme temperatures can affect rope integrity. Regular inspections are essential to ensure safety. The balance between innovation and risk management is crucial for effective operations. As the industry evolves, embracing new materials requires continuous learning and adaptation.

In 2026, safety standards are pivotal in selecting crane ropes. Compliance with regulations can impact operational efficiency and worker safety. The American National Standards Institute (ANSI) recommends regular inspections and comprehensive training for crane operators. Failure to adhere to these guidelines puts workers at risk and could lead to costly accidents.

Different rope types will have varying levels of compliance and safety ratings. For instance, synthetic ropes offer greater flexibility and lower weight, but may not meet all standards under certain conditions. A report by the Occupational Safety and Health Administration (OSHA) indicated that inadequate testing of crane equipment was responsible for 30% of accidents in the field. This fact emphasizes how critical it is to choose ropes that not only meet but exceed safety benchmarks.

Rope selection isn't just about strength. It also involves understanding the environmental factors at the job site. High temperatures, moisture, or chemicals can degrade rope materials. The International Organization for Standardization (ISO) has established guidelines that suggest assessing these conditions during the selection process. Even then, frequent evaluations are essential, as environmental impacts can be unpredictable.