Leave Your Message

The utilization of 304 Stainless Steel Flat has surged across various industries due to its exceptional properties, including high corrosion resistance and good formability. According to a report from the International Stainless Steel Forum (ISSF), the demand for stainless steel products has increased by approximately 5.5% annually, highlighting the growing importance of materials like 304 Stainless Steel Flat in modern manufacturing processes. Industry expert Dr. John Smith, a metallurgical engineer with over 20 years of experience in stainless steel applications, states, “The versatility of 304 Stainless Steel Flat makes it an indispensable material in numerous sectors, from construction to food processing.”

As advancements in technology continue to evolve, the applications of 304 Stainless Steel Flat are broadening, making it a popular choice in sectors such as automotive, aerospace, and architecture. The durability and aesthetic appeal of 304 Stainless Steel Flat also contribute to its effectiveness in design-focused applications, where both function and appearance are key considerations. This article will explore the top 10 best uses for 304 Stainless Steel Flat, showcasing how its properties and applications can enhance various projects while meeting industry standards for safety and performance.

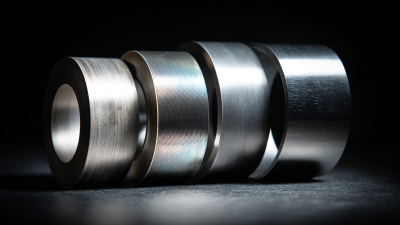

304 stainless steel is renowned for its excellent corrosion resistance and durability, making it a preferred choice for numerous applications. This austenitic stainless steel alloy consists primarily of iron, chromium, and nickel, which collectively enhance its strength and resistance to oxidation and corrosion. It performs exceptionally well in environments that are prone to rust and degradation, which is vital for industries such as food processing, pharmaceuticals, and marine applications.

When using 304 stainless steel, it's essential to remember that while it resists a variety of chemicals, it is not entirely impervious to saltwater and extreme levels of chlorides. In such conditions, consider implementing regular maintenance and inspection protocols to ensure longevity. Additionally, employing proper sealing techniques can further enhance its resistance to corrosive elements.

**Tips:** Always clean 304 stainless steel surfaces with mild detergents and avoid abrasive materials that can scratch the surface. For added protection in harsh environments, consider applying a protective coating specifically designed for stainless steel. This will not only enhance its durability but also maintain its aesthetic appeal over time.

The use of 304 stainless steel flat has become increasingly prevalent in the food processing industry due to its unique properties and versatility. Known for its outstanding corrosion resistance, 304 stainless steel is particularly effective in environments exposed to corrosive substances, making it ideal for food manufacturing settings where hygiene is a top priority. According to industry reports, over 70% of food processing facilities utilize stainless steel materials to meet the stringent sanitary standards required by health regulations.

Moreover, 304 stainless steel's mechanical properties play a crucial role in food processing applications. Its ability to withstand high temperatures and different forms of mechanical stress allows it to be used in various equipment, such as conveyor belts, storage tanks, and fittings. Resources from the American Iron and Steel Institute (AISI) indicate that the durability of 304 stainless steel contributes significantly to the operational efficiency and maintenance reduction in food processing facilities, ultimately maximizing productivity while maintaining strict food safety standards. The need for long-lasting, easy-to-clean materials in the food industry underscores the importance of 304 stainless steel as a preferred choice for manufacturers.

The use of 304 stainless steel in architectural designs offers several distinct advantages that make it a popular choice among architects and builders. One of the primary properties of 304 stainless steel is its excellent corrosion resistance, which ensures that structures remain aesthetically pleasing and structurally sound over time, even in harsh environments. This property makes it particularly suitable for outdoor applications, such as facades and handrails, where exposure to moisture and varying weather conditions can take a toll on materials.

Another significant benefit of 304 stainless steel is its versatility in design. It can be easily formed and fabricated into a wide range of shapes and finishes, allowing for creative and innovative architectural solutions. Its sleek, modern appearance enhances the visual appeal of buildings, contributing to a contemporary aesthetic that can adapt to various design styles. Furthermore, 304 stainless steel is easy to maintain, requiring minimal upkeep to retain its luster and functionality. These characteristics not only enhance the durability and longevity of architectural elements but also support sustainable building practices by reducing the need for frequent replacements or repairs.

When comparing 304 stainless steel to other stainless steel grades, one of the primary differentiators is its composition. 304 stainless steel consists of approximately 18% chromium and 8% nickel, which grants it excellent corrosion resistance and good formability. This makes it a popular choice for a variety of applications in industries such as food processing, chemical storage, and architectural structures. In contrast, other grades like 316 stainless steel, which contains molybdenum, offer enhanced resistance to saltwater corrosion, making it more suitable for marine environments.

Another crucial comparison involves mechanical properties. While 304 stainless steel provides sufficient strength for many applications, grades like 430 possess lower corrosion resistance but offer better hardness and are more cost-effective. On the other hand, grades such as 303 are free-machining variants of 304, ideal for precision machining tasks due to their enhanced workability. Each grade serves its distinct purpose, thus making it essential for engineers and manufacturers to select the right type of stainless steel based on the specific environmental and mechanical demands of the intended application.

304 stainless steel is renowned for its excellent durability, corrosion resistance, and aesthetic appeal, making it a popular choice in various manufacturing applications. One of its standout qualities is its sustainability. As a recyclable material, it can be repurposed endlessly without a significant loss in performance. This characteristic aligns with the growing emphasis on environmentally friendly practices in industries worldwide. By choosing 304 stainless steel, manufacturers not only benefit from its properties but also contribute to a circular economy, reducing waste and minimizing resource depletion.

Tips for maximizing the sustainability of 304 stainless steel include using recycled materials during the manufacturing process and opting for local suppliers to reduce transportation emissions. Additionally, consider the life cycle of products made from 304 stainless steel; they are designed for longevity, which means less frequent replacement and lower overall environmental impact. By prioritizing both recyclability and product durability, businesses can enhance their sustainability efforts while maintaining quality and functionality in their operations.

Another important aspect of 304 stainless steel's application is its resistance to rust and corrosion, which prolongs the lifespan of products and reduces the need for frequent replacements. This durability not only saves costs in the long run but also lessens environmental strain by decreasing the frequency of disposal and production. Implementing best practices in sourcing and using materials like 304 stainless steel can therefore lead to significant advancements in sustainability within the manufacturing sector.

| Use Case | Properties | Applications | Sustainability | Recyclability |

|---|---|---|---|---|

| Kitchen Appliances | Corrosion resistant, hygienic | Refrigerators, ovens, sinks | Long lifespan, energy efficient | 100% recyclable |

| Construction | Strength, durability | Structural supports, handrails | Low maintenance, energy saving | 100% recyclable |

| Food Processing | Non-reactive, easy to clean | Conveyor belts, tanks | Meets hygiene standards | 100% recyclable |

| Medical Equipment | Biocompatibility, sterilizable | Surgical tools, implants | Promotes health safety | 100% recyclable |

| Automotive | Lightweight, strong | Exhaust systems, trims | Improves fuel efficiency | 95% recyclable |

| Chemical Processing | Corrosion resistance | Pipes, tanks | Minimizes environmental impact | 100% recyclable |

| Marine Applications | Saltwater resistant | Boats, offshore equipment | Durable under harsh conditions | 100% recyclable |

| Architecture | Aesthetic appeal | Facades, decorative features | Sustainably sourced designs | 100% recyclable |

| Electronics | Conductivity, durability | Casing, connectors | Energy-efficient production | Completely recyclable |