Leave Your Message

When it comes to selecting materials for projects, the choice of steel can significantly influence the outcome. Many industry experts, including Dr. Helen Carter, a specialist in metal properties, emphasize the importance of using high-quality materials. She once remarked, "Using 316 Stainless Steel Plate can elevate your project's performance and longevity."

316 Stainless Steel Plate is known for its remarkable resistance to corrosion and heat. This makes it a preferred option in marine and chemical environments. Many builders and engineers favor it for high-demand applications. However, some still overlook its benefits. They may opt for cheaper alternatives. This decision can lead to higher long-term costs due to maintenance and replacement needs.

Investing in 316 Stainless Steel Plate is often seen as a sound strategy. The material's strength and durability provide reassurance. Yet, there are situations where its use might not be justified. Careful consideration and proper application are crucial. An unfocused choice can affect project outcomes negatively, even with a quality material like 316 Stainless Steel Plate.

When it comes to construction projects, choosing the right materials matters. 316 stainless steel stands out due to its impressive durability. This alloy can resist corrosion from harsh environments. It is especially valuable near oceans or industrial sites. The added molybdenum enhances its resistance to pitting. This feature is crucial for long-lasting structures.

Another notable benefit is its thermal stability. 316 stainless steel maintains its strength at high temperatures. This property is essential for projects involving heat exposure. However, its cost can be a concern for some. Sometimes, alternative materials appear more budget-friendly. Yet, the longevity and reduced maintenance of 316 steel often justify the investment.

In addition to practical benefits, aesthetics also play a role. The smooth finish of 316 stainless steel provides a modern appeal. It enhances the look of buildings, bridges, and other structures. Some might find it too shiny for certain designs. Striking a balance between aesthetics and functionality is key. However, the strength and resilience typically make it a preferred choice.

316 stainless steel plates are widely used across many industries due to their remarkable properties. In the food processing sector, these plates are essential. They resist corrosion from acids and chemicals. This makes them ideal for manufacturing equipment in environments with strict hygiene standards.

In marine applications, 316 stainless steel excels too. Its excellent rust resistance ensures longevity in harsh saltwater conditions. Shipbuilding and offshore structures benefit greatly. The durability allows these constructions to last longer despite facing challenging environments.

However, it’s important to consider the cost. While 316 stainless steel offers great performance, it can be pricier than other options. Projects with tight budgets may struggle. A careful evaluation of needs and costs is crucial. Overall, 316 stainless steel plates serve various industries, providing durability and strength where needed.

316 stainless steel plates are renowned for their excellent corrosion resistance, durability, and strength, making them ideal for various applications across industries. The following chart illustrates the common applications of 316 stainless steel plates in different sectors.

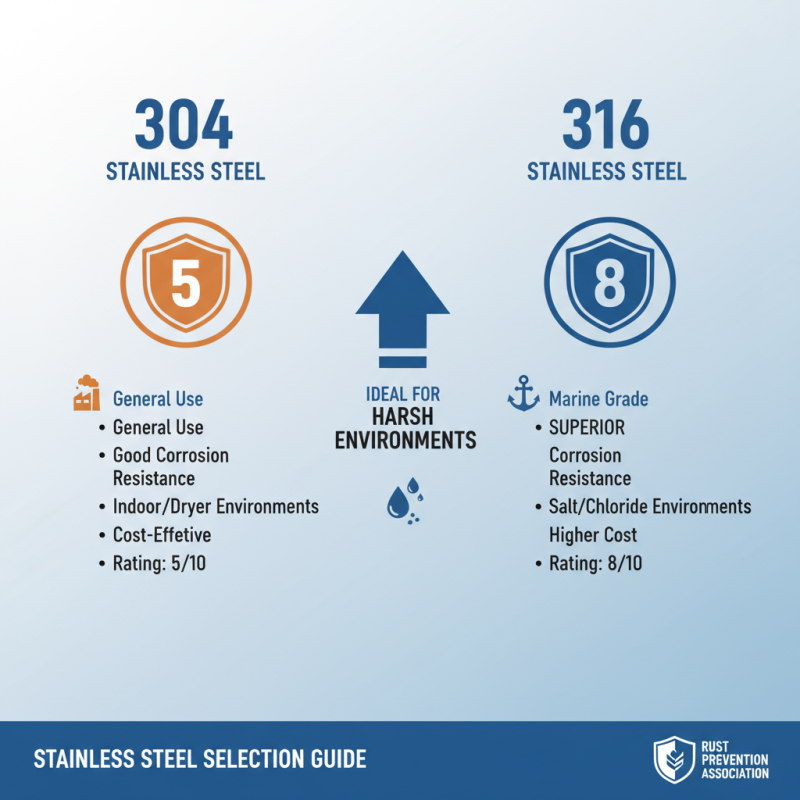

When selecting stainless steel for projects, 316 stainless steel often stands out. It offers superior corrosion resistance compared to 304 stainless steel. This is particularly vital in marine environments or industries facing high saline exposure. A report from the Rust Prevention Association indicates that 316 stainless steel has a corrosion resistance rating of 8, while 304 scores only 5.

The strength and durability of 316 make it ideal for critical applications. This grade remains stable at high temperatures, around 870°C. In contrast, other grades like 430 stainless steel can start to lose their properties much earlier. However, 316 stainless steel is generally more expensive than 304, which might lead to budget concerns.

Tips: Consider the project environment. If it’s coastal, definitely lean towards 316. Also, weigh the importance of longevity in your decision. While 316 may cost more upfront, it usually saves money in maintenance and replacement costs.

It's essential to recognize that while 316 stainless steel is robust, it isn’t infallible. Over time, harsh chemicals can still affect it. Understanding specific needs is key to choosing the right grade. Consider all possible scenarios before making a choice.

When choosing 316 stainless steel plates for your projects, several factors must be considered. The most notable is corrosion resistance. 316 stainless steel has superior resistance to rust and corrosive substances. This makes it ideal for marine applications and environments with harsh chemicals. However, the choice may depend on specific exposure conditions.

Another vital aspect is the thickness of the plate. Thicker plates offer enhanced durability but increase weight. Balancing between sturdiness and manageability is crucial. Furthermore, you should consider fabrication capabilities. Not all suppliers offer the same services. Understanding your project’s requirements will help ensure that the steel can be readily shaped or welded.

Cost is often a deciding factor, too. Although 316 stainless steel is more expensive than other types, its longevity can lead to savings in the long run. Still, budget constraints can complicate decisions. You may need to compromise on type or quality to fit within your budget. Reflecting on these aspects will guide you toward making an informed choice.

When it comes to 316 stainless steel plates, keeping them well-maintained is crucial for their longevity. These plates offer excellent corrosion resistance, but they still require some care. Regular cleaning helps prevent dirt and grime buildup. A simple wash with mild soap and water can go a long way. For tougher stains, consider using a non-abrasive cleaner.

Consider the environment where the stainless steel plate will be used. Factors like humidity and exposure to salt can lead to corrosion over time. It's wise to apply a protective layer, especially in coastal areas. Ensure proper drainage around the installation to avoid stagnant water. Choose furniture or fixtures that complement the plate without scratching the surface.

Inspecting your plates regularly is vital. Look for signs of wear or corrosion. Immediate action can save you from costly repairs later. Sometimes, subtle changes are hard to notice, but they can impact the plate's integrity. Don't hesitate to reach out if you have concerns about the condition of your stainless steel. Careful monitoring and maintenance contribute significantly to its durability.