Leave Your Message

In the world of lifting equipment, few components are as vital as Hoist Steel Wire Rope. John Smith, a renowned expert in crane operations, emphasizes its significance, stating, “Reliable lifting depends on the quality of your wire rope.” This statement highlights not only the importance of material quality but also the overall safety of lifting operations.

Choosing Hoist Steel Wire Rope means investing in durability and strength. Different applications require various specifications. For instance, a construction site might stress the rope differently than a warehouse. It’s essential to consider load capacity and flexibility. Relying on subpar rope can lead to accidents.

Moreover, users should be aware of maintenance needs. Regular inspections can prevent failures over time. Some tender this aspect lightly, but neglecting it can prove costly. Ultimately, Hoist Steel Wire Rope remains a cornerstone of safe lifting practices, but it demands respect and care.

Hoist steel wire rope is a popular choice for many industrial applications. Its strength and durability make it ideal for heavy lifting tasks. The rope can withstand extreme tension and provides reliable performance over time. Users often appreciate its ability to handle loads that exceed expectations.

In various industries, hoist steel wire rope shows its versatility. It is used in construction, manufacturing, and shipping. The rope's resistance to abrasion and fatigue ensures longevity. However, maintenance is crucial. Regular inspections can help identify wear and tear. Neglecting this can lead to accidents or equipment failure.

Flexibility is another advantage, allowing it to fit different systems. Operators must adapt it to various setups in real scenarios. Some users find it challenging to select the right diameter or lay type. This requires careful consideration of load requirements. Overall, hoist steel wire rope proves beneficial, yet it demands attention and understanding from users.

When it comes to lifting needs, selecting the right steel wire rope is crucial. Hoist steel wire ropes are designed to offer remarkable strength and durability. This means they can handle heavy loads without compromising safety. They feature a high tensile strength, ensuring they can withstand intense pressure. Additionally, the ropes are often coated for enhanced resistance to wear and environmental factors.

Durability is essential for long-term use. Hoist steel wire ropes are known for their ability to resist corrosion and abrasion. This longevity makes them a reliable choice for various applications. However, it is vital to ensure the correct specifications match the intended use. Not all situations require the same type of rope. Misalignment can lead to accidents or equipment failure.

It’s important to pay attention to key specifications such as diameter and construction type. These factors directly influence performance and safety. Regular inspection of the ropes is necessary. Neglecting this can result in unexpected failures. Understanding these specifications and maintaining them appropriately is key to effective lifting operations.

When choosing a lifting solution, the materials you select play a significant role in safety and efficiency. A study by the International Journal of Engineering and Technology highlights that steel wire rope can carry a load up to 5 times its weight. This makes it a robust choice compared to synthetic alternatives. However, the dynamic nature of lifting operations can lead to wear and tear on both materials and mechanisms.

Alternative solutions, such as synthetic ropes, weigh less and are easier to handle. Yet, they typically have lower fatigue resistance. Reports suggest that synthetic ropes can lose 30% of their strength after just a few months of use in demanding conditions. This can lead to increased downtime and maintenance costs.

**Tip:** Regular inspection of any lifting gear is crucial. Look for signs of fraying or wear. Even strong materials must be replaced if they show damage.

Additionally, while steel wire ropes need proper lubrication and maintenance, they can offer superior durability. However, many users overlook this aspect, potentially leading to premature failures. The choice depends on your specific lifting conditions, so weigh the pros and cons carefully.

**Tip:** Consider the environment your equipment will operate in. Corrosion can significantly affect steel wire, while UV damage can harm synthetic ropes.

This chart compares the weight capacity of various lifting solutions including Hoist Steel Wire Rope, Synthetic Rope, Chain Sling, and Webbing Sling. Hoist Steel Wire Rope offers the highest weight capacity, making it a top choice for heavy lifting needs.

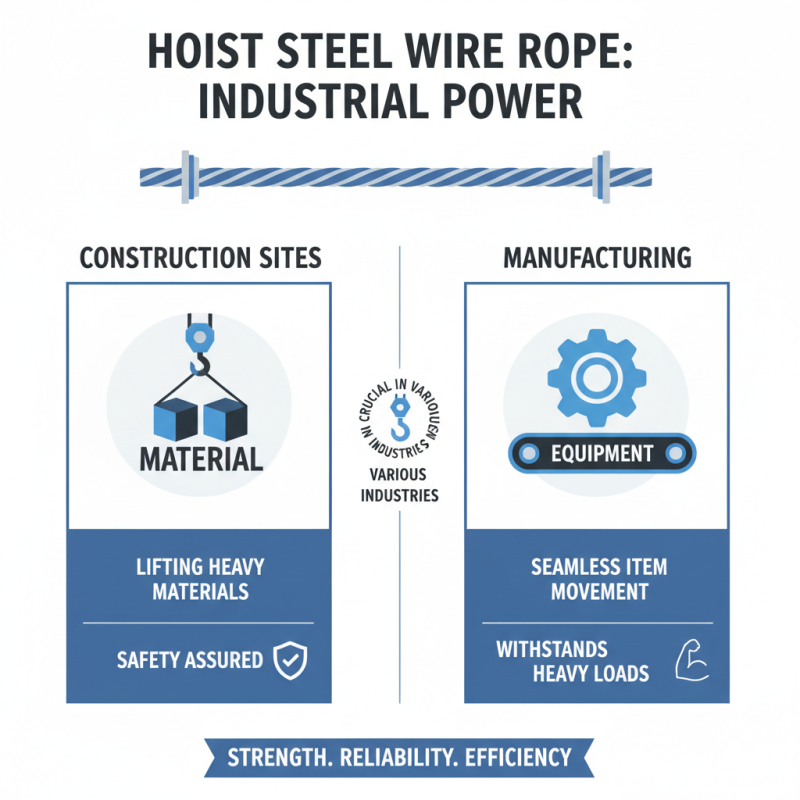

Hoist steel wire rope is crucial in various industries. Construction sites often utilize it for lifting heavy materials. The strength of the wire rope ensures safety during these operations. In manufacturing, this rope is employed to move large items seamlessly. It withstands heavy loads, which is essential in a busy factory.

Shipping and transportation industries also rely on this robust material. Hoist steel wire rope helps secure cargo on ships and trucks. It provides reliability against harsh weather conditions. Mining operations use it extensively for transporting minerals from deep underground. The durability of the rope is vital in these extreme environments.

However, users must regularly check the condition of the wire rope. Over time, wear and tear can compromise its integrity. Inspections should be routine, especially in high-stress applications. Training for operators is essential, too. They should understand the limits of the rope and recognize signs of deterioration. Proper maintenance is critical to ensure safety and efficiency in all applications.

Safety is paramount when using hoist steel wire rope for lifting. Compliance with industry standards is critical. The American National Standards Institute (ANSI) and Occupational Safety and Health Administration (OSHA) provide guidelines that ensure safe practices. Statistical data shows that around 18,000 injuries occur annually due to improper lifting equipment use. This highlights the need for adherence to safety protocols.

Inspecting steel wire ropes regularly is vital. A study by the Institute of Inspection, Cleaning and Restoration Certification (IICRC) emphasizes that 30% of failures result from inadequate maintenance. Users must be trained to identify wear and tear signs. More importantly, they should know when to replace ropes. This knowledge can reduce accident rates and enhance workplace safety.

For many, choosing the right wire rope can be challenging. Understanding specifications, such as load limits and environmental factors, is essential. Failure to grasp these details may lead to overloading. Interestingly, some operators still underestimate the significance of load ratings. Continuous education on safety compliance can empower workers. It can also protect against costly accidents and ensure a safe working environment.

| Feature | Importance | Compliance Standard | Load Capacity (Ton) |

|---|---|---|---|

| High Breaking Strength | Ensures safety during lifting operations | ISO 4309 | 5 |

| Corrosion Resistance | Enhances longevity and durability | ASTM A313 | 3 |

| Flexible Design | Facilitates easy handling and installation | EN 12385 | 10 |

| High Fatigue Resistance | Reduces risk of failure under repeated use | ISO 10247 | 8 |

| Safety Factor | Provides an extra margin of safety | ASME B30.2 | 12 |