Leave Your Message

When selecting 304 Stainless Steel Flanges for a project, the right choice can greatly impact performance and reliability. John Smith, a renowned expert in the field, once stated, "Choosing the right flange is crucial for the integrity of your piping system." This highlights the importance of understanding the specifications and applications of 304 Stainless Steel Flanges.

These flanges are celebrated for their corrosion resistance and durability. However, many people overlook critical factors such as pressure ratings and gasket compatibility. A wrong choice can lead to leaks or even system failures. It's not always clear which type is most suitable for a specific application, which adds to the challenge.

Additionally, while 304 Stainless Steel Flanges are versatile, they do have limitations. For example, they may not perform well in extremely high-temperature environments. Recognizing these nuances is vital. As you embark on your project, reflect on these details. Your choice of 304 Stainless Steel Flanges can influence the entire system's success.

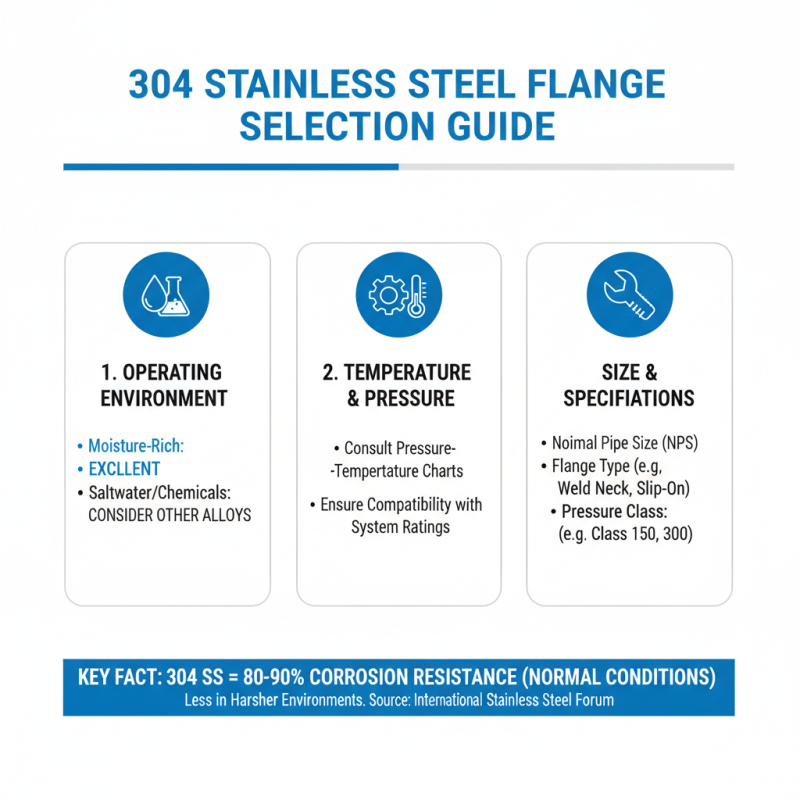

Selecting the right 304 stainless steel flanges for your project requires careful consideration of several key factors. First, assess the operating environment. 304 stainless steel offers excellent corrosion resistance, particularly in environments rich in moisture. However, exposure to saltwater or chemicals may require a different alloy. According to a study by the International Stainless Steel Forum, 304 stainless steel has a corrosion resistance that is 80-90% effective under normal conditions, but this might fall short in harsher environments.

Next, think about the pressure and temperature ratings. Flanges must withstand specific conditions without compromising functionality. ASME B16.5 provides guidelines for selecting flanges based on these parameters. Notably, 304 flanges typically support pressures up to 300 psi at moderate temperatures. Yet, under elevated temperatures, their strength may decrease, leading to potential failures. Monitoring these details during the selection process is crucial, as neglecting them can lead to costly repairs.

Lastly, consider the flange size and connection type. Flanges must match the pipe dimensions precisely. A mismatch can lead to leaks or even catastrophic failures. The ASTM A182 standard specifies the dimensions and tolerances for flanges. However, many manufacturers may not adhere strictly to these standards, resulting in variations. Ensure thorough quality checks to avoid such discrepancies that can compromise project integrity. Keep an eye on these factors. Your project’s success depends on it.

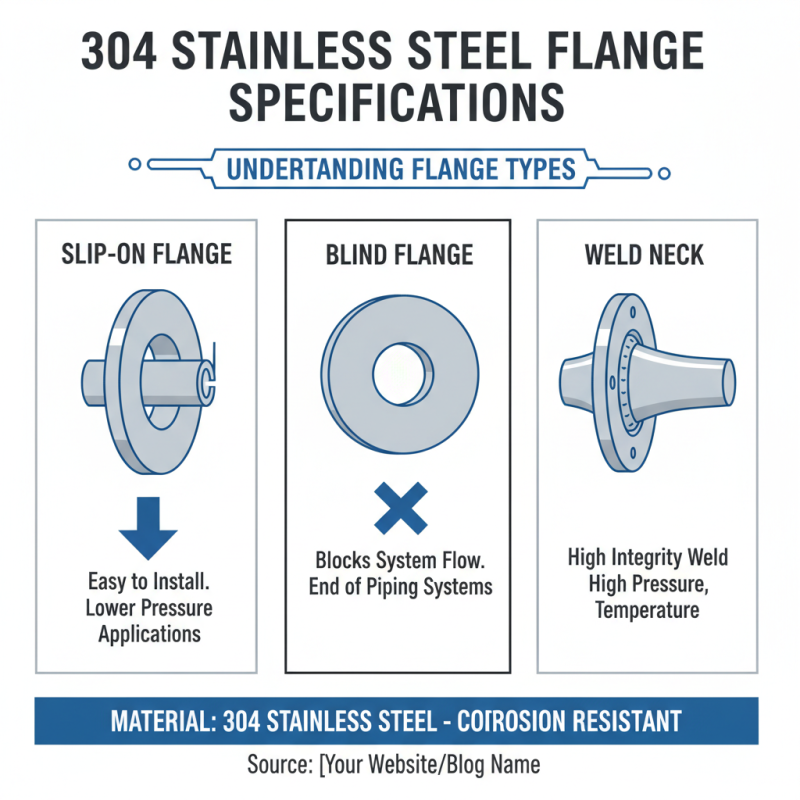

When selecting 304 stainless steel flanges, understanding the types available is crucial. There are several common types: slip-on, blind, threaded, and welded. Each type serves a unique purpose and fits different applications. Slip-on flanges are easy to install and are ideal for piping systems where alignment is flexible.

Blind flanges, on the other hand, are used to close off ends of a piping system. They prevent the flow of liquids or gases and are essential in testing systems. Threaded flanges work well when welding isn't an option. They screw onto the pipe, making them easier to disassemble. However, they are less reliable under high pressure.

In some cases, choosing the wrong type can lead to leaks or failure. Many overlook the environment where flanges will be used. For instance, exposure to chemicals can affect their durability. Each application may need a specific type of flange to ensure safety and efficiency. Remember, every choice matters in the long run.

When selecting 304 stainless steel flanges, it’s crucial to understand the specifications. Flanges come in various types, each serving specific needs. Common types include slip-on, blind, and weld neck flanges. Each type has unique properties that affect performance. For example, slip-on flanges are easy to install, while blind flanges block systems.

Standards play a significant role in ensuring compatibility and safety. The American National Standards Institute (ANSI) provides guidelines for dimensions and pressure ratings. These standards help prevent mismatched components. You must also consider the environmental factors affecting your project. Factors like temperature and corrosive elements can impact durability and reliability.

It’s important to recognize that not all flanges are created equal. Many might overlook the importance of proper sealing surfaces. Imperfections in these surfaces can lead to leaks or failures. Evaluating the need for additional gaskets or fasteners may be necessary. Additionally, consider the finish; a polished surface may provide better corrosion resistance. Reflecting on these aspects can lead to better decisions for your project.

When selecting 304 stainless steel flanges, cost and quality play crucial roles. Prices can vary widely among different suppliers. Some flanges might appear cheap, but their durability is often questionable. Investing in a slightly higher-priced flange may save money in the long run, as it could reduce maintenance costs.

Quality assessment is essential. Look for flanges with a consistent finish and no scratches. Check the manufacturer’s specifications for material purity. A lower-quality flange might not withstand pressure effectively. Flanges that warp or rust quickly can lead to project delays.

Comparing various brands is a good strategy. Ask for samples and inspect them closely. Flanges that look good on the surface may hide defects. Don’t just focus on price. Evaluate how each option fits your project needs. Testing different flanges in real conditions can provide insights. This approach prevents regrettable choices later on.

When installing 304 stainless steel flanges, proper attention to detail is crucial. According to industry reports, incorrect installation can lead to leaks and system failures, which can be costly. The recommended torque specifications for bolting flanges should always be followed. Ignoring this may result in flange warping or gasket failure. It’s essential to use a calibrated torque wrench for accuracy.

During maintenance, regular inspections are necessary. Look for signs of corrosion or wear, especially in high-stress environments. Even though 304 stainless steel is resistant to many chemicals, it is not immune to pitting corrosion. A study highlighted that about 20% of stainless steel failures are due to insufficient maintenance. Cleaning should be done using mild detergent and water. Harsh chemicals can strip protective layers, which can lead to premature degradation.

Consider the environment where the flanges will be used. Humid or corrosive conditions may affect the flange integrity. Although 304 stainless steel is versatile, it might not perform well in all situations. Assess your project’s requirements carefully. If you overlook environmental factors, it can lead to performance issues later. Monitoring and adjusting your maintenance routines based on real-world conditions may prevent unexpected failures.