Leave Your Message

Choosing the right 304 Stainless Steel Pipe for your project can be challenging. This material has numerous benefits, but also some limitations. As industry expert John Smith states, "Selecting the proper pipe is vital for a successful outcome." Understanding the specific requirements of your project is crucial.

When evaluating 304 Stainless Steel Pipes, consider factors like diameter, wall thickness, and intended use. Each project has unique demands. For instance, using the wrong thickness can lead to premature failure. You might wonder how these variables affect performance.

Moreover, there's a need for quality assurance. Not all suppliers provide the same level of reliability. A trusted source offers certified materials, which may seem tedious to verify. However, this step is essential to ensure longevity and performance. Some installers overlook the necessity of proper welding techniques, leading to costly repairs later. Reflecting on these aspects will help in making a better-informed decision regarding 304 Stainless Steel Pipes.

When selecting a 304 stainless steel pipe, understanding its properties is crucial. 304 stainless steel is known for its excellent corrosion resistance. This makes it suitable for a wide range of applications. It holds up well in harsh environments, from outdoor settings to food processing.

The ductility of 304 stainless steel is another key property. This material can be easily formed into various shapes without losing strength. It remains strong yet flexible, which can be a significant advantage in construction. However, one must be aware of its limitations. 304 steel is not suitable for high-salt environments. In coastal areas, exposure to saltwater can lead to pitting.

Another thing to consider is the finish of the pipe. A smooth finish can enhance its appearance and performance. Yet, sometimes, a rough finish might be required for specific applications. It’s important to weigh these factors carefully before making a choice. Choosing the wrong pipe can lead to issues down the line. The properties should align closely with the project requirements for optimal results.

This bar chart displays the key mechanical properties of 304 stainless steel pipe, including tensile strength, yield strength, elongation, and hardness. Understanding these properties is essential for selecting the right pipe for your project.

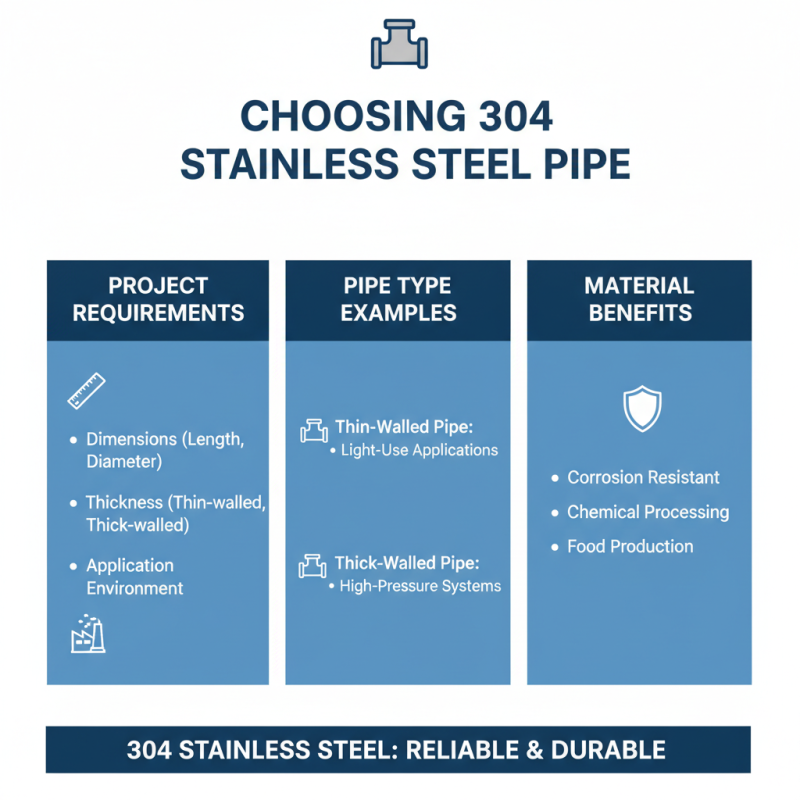

When choosing the right 304 stainless steel pipe, understanding your project's specific requirements is crucial. The dimensions, thickness, and application environment play key roles. For example, you might need a thin-walled pipe for light-use applications, while a thicker option could be necessary for high-pressure systems. According to industry reports, 304 stainless steel is highly resistant to corrosion, which makes it suitable for various environments, including chemical processing and food production.

Tip: Always assess the pipe's yield strength. It should align with your project demands. For instance, if the pipe experiences stress from movement, a yield strength of around 215 MPa is typically desired. Materials also need to handle thermal expansion adequately, especially in fluctuating temperature conditions.

Don't overlook the importance of proper sealing and fittings. These can impact overall project safety and functionality. Improper seals may lead to leaks, which can prove costly. Some sources suggest that up to 30% of installation failures stem from poor connections. Thus, investing time to ensure the right fittings is as crucial as selecting the correct pipe.

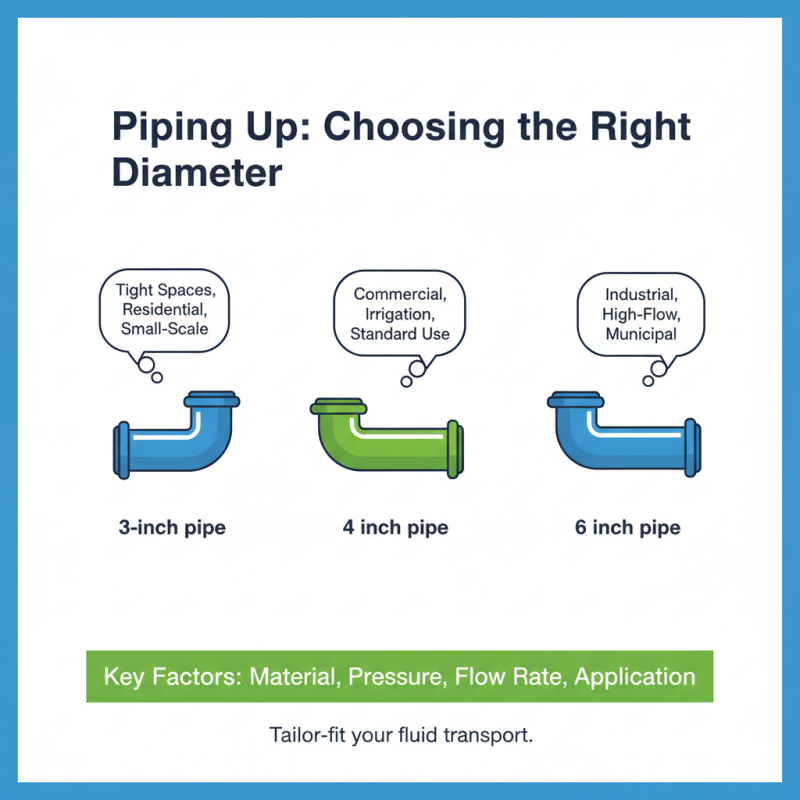

When selecting a 304 stainless steel pipe, dimensions matter. Different projects require various sizes. A slight difference can impact functionality and aesthetics. For instance, a 3-inch pipe may fit well in tight spaces, while a 6-inch one suits industrial needs. Knowing your requirements is crucial.

Measuring the outside diameter and wall thickness is essential. These dimensions affect both strength and weight. Is the pipe intended for structural support or fluid transport? Those factors dictate thickness and diameter choices. Sometimes, broader pipes can look visually appealing but add unnecessary weight. Analyzing your specific needs is vital.

Misjudging dimensions can lead to costly mistakes. A pipe that is too small may not hold sufficient pressure. Conversely, an oversized pipe can be challenging to install. Always review your project requirements and potential limitations. Consider the environment where the pipe will be installed, too. Each setting presents unique challenges, and reflecting on these aspects can guide better choices.

When selecting a 304 stainless steel pipe for your project, comparing costs and quality among different suppliers is crucial. Prices can vary significantly. Some suppliers may offer low prices but compromise on quality. This can lead to unexpected expenses later. High-quality pipes often save costs due to their durability and resistance to corrosion.

Consider these tips when evaluating suppliers. Check if they provide certifications for their products. This ensures that the pipes meet industry standards. Ask about their sourcing practices. Sustainable sourcing can sometimes result in higher costs, but it may be worth it. Think about the long-term benefits.

Don't overlook delivery times and customer support. A lower price may not be worth delays or poor service. A supplier’s responsiveness can indicate their overall reliability. You might find that the best option is not the cheapest one. Sometimes, investing in quality pays off over time.

When installing 304 stainless steel pipes, proper maintenance is crucial. Regular inspections help identify any signs of corrosion. Corrosion can happen even in stainless steel over time due to environmental factors. According to a report from the National Association of Corrosion Engineers, nearly 50% of failures in industrial pipes are linked to avoidable corrosion issues.

Cleaning the pipes is another important step. Using a gentle detergent solution can remove dirt without causing damage. Avoid abrasive cleaners that scratch the surface. A study from the International Stainless Steel Forum indicates that cleaning stainless steel regularly can extend its lifespan by up to 30%.

Installation technique also matters. Pipes should be aligned properly to avoid stress points. Misalignment can lead to leaks. The American Society of Mechanical Engineers notes that improper installation can cause up to 20% of failed connections in piping systems. Regularly reviewing your installation practices can help minimize these risks.