Leave Your Message

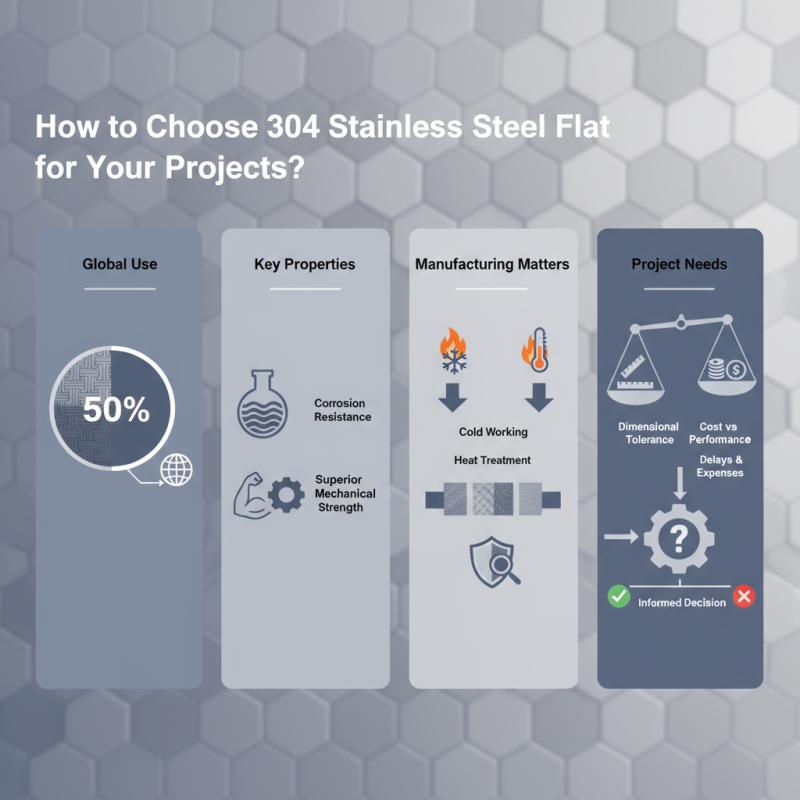

When selecting materials for construction or manufacturing, the choice of 304 Stainless Steel Flat is crucial. This alloy accounts for approximately 50% of all stainless steel usage worldwide. Its popularity stems from its excellent corrosion resistance and superior mechanical properties. Projects ranging from automotive to kitchenware benefit greatly from its unique features.

However, not all 304 Stainless Steel Flats are created equal. Variations in manufacturing processes can impact strength and durability. For instance, factors such as cold working and heat treatment directly influence the material's performance. A report from the International Stainless Steel Forum highlights that inconsistency remains a challenge, urging buyers to vet suppliers carefully.

As detailed specifications matter, potential users must reflect on their project needs. Consideration should be given to factors like tensile strength and dimensional tolerance. Selecting the right grade of 304 Stainless Steel Flat means balancing cost with performance. Failing to do so can lead to project delays and increased expenses. Thus, careful evaluation is essential in making an informed decision.

304 stainless steel is a popular choice for numerous projects. It combines excellent corrosion resistance with good mechanical properties. This type of stainless steel has a unique composition of 18% chromium and 8% nickel. This blend offers a balance of strength and ductility.

One significant benefit is its temperature tolerance. 304 can withstand temperatures up to 870°C (1,600°F) without significant deformation. This quality makes it suitable for both kitchen equipment and structural applications. According to industry reports, 304 stainless steel has a tensile strength of around 507 MPa (73,000 psi). Despite its advantages, it may not be ideal for all applications. It's less resistant to chloride-induced corrosion compared to other grades.

The maintenance aspect is also important. Regular cleaning can enhance its appearance and longevity. Neglecting this can lead to pitting and discoloration. While 304 can be durable, it is not entirely impervious to damage. In environments with harsh chemicals, it may show signs of wear faster than expected. Understanding these properties helps in making an informed choice for your specific needs.

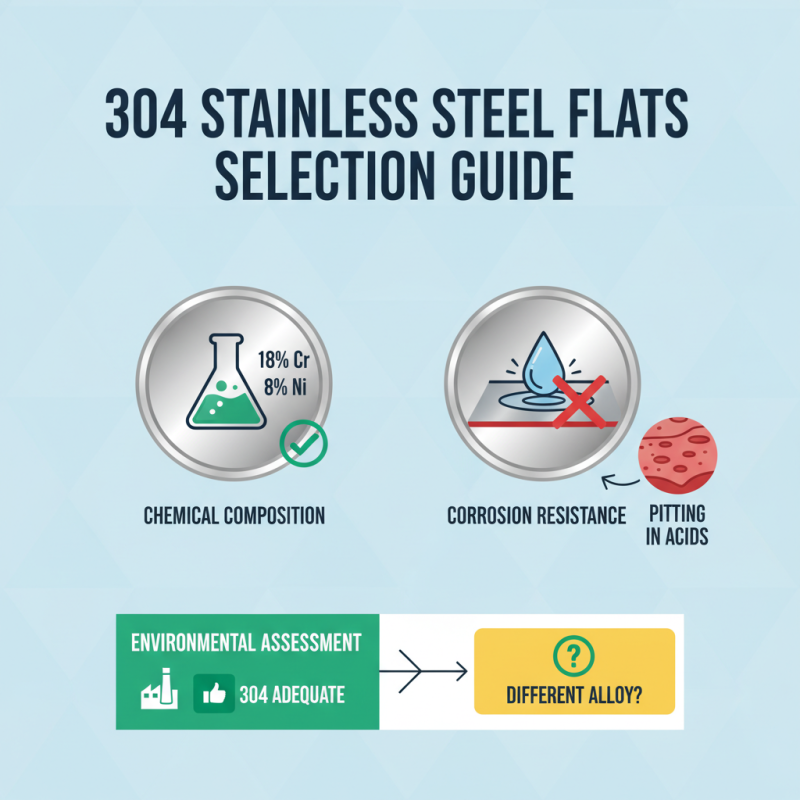

When selecting 304 stainless steel flat, there are several critical factors to consider. The chemical composition of 304 stainless steel includes approximately 18% chromium and 8% nickel. This gives it excellent corrosion resistance. However, in highly acidic environments, this alloy may still suffer from pitting. It’s essential to evaluate the environment where the material will be used. This assessment will help determine if 304 is adequate or if a different alloy would perform better.

Another important factor is the thickness and width of the flat stock. The thickness often ranges from 0.125 inches to over 0.5 inches. For structural applications, a thicker gauge may be required to support specific loads. In contrast, thinner options are available for decorative applications. Pay attention to fabrication needs as well. Some projects may involve bending or welding, which can impact the integrity of 304 stainless steel. Proper techniques must be used to avoid warping or weakening the material.

It's also beneficial to consider the surface finish of the flat stainless steel. Options include polished, brushed, or mill finishes. Each finish has unique properties affecting aesthetics and functionality. For instance, a polished finish might look great, but it can be more prone to scratches. Statistical reports suggest that around 40% of structural failures in steel projects are due to improper processing. Such data reinforces the need for careful selection and handling of 304 stainless steel flat to ensure project success.

304 stainless steel flat is a popular choice across many industries. Its versatility makes it ideal for various applications. In construction, it serves as structural support. It exhibits excellent corrosion resistance, especially in harsh environments. Many architectural designs incorporate this material for both strength and aesthetics.

In the food and beverage industry, 304 stainless steel flat is crucial. It’s used in equipment such as conveyors and storage tanks. This grade is easy to clean and maintain, ensuring hygiene. Furthermore, it can withstand the production of acids. Many manufacturers rely on this material for durability.

Tips: When selecting 304 stainless steel flat, consider the dimensions carefully. Measure your project’s specific requirements. Look for consistency in flatness and surface finish. A flawed piece might not fulfill your needs effectively. Always source your materials from reputable suppliers to mitigate risks. This can save you time and money in the long run.

When comparing 304 stainless steel to other types, key distinctions emerge. 304 stainless steel is known for its high corrosion resistance and excellent weldability. It consists of 18% chromium and 8% nickel, giving it a unique balance of strength and ductility. However, it's essential to understand its limitations. The material may not perform as well in high-temperature environments compared to alloys like 316 stainless steel, which adds molybdenum for enhanced performance in extreme conditions.

Looking at industry data, a report by the International Stainless Steel Forum notes that 304 stainless steel accounts for about 60% of global stainless steel usage. This is mainly due to its versatility in various applications, from kitchen equipment to architectural structures. Nevertheless, it’s crucial to recognize that this popularity can lead to oversights. Users may mistakenly assume 304 is suitable for every scenario. For instance, environments with chlorides can lead to pitting corrosion in 304, something a marine-grade steel would resist.

In short, while 304 stainless steel has much to offer, it’s not a one-size-fits-all solution. Factors like environmental conditions and specific project requirements should guide your choice. Evaluating the long-term performance and potential weaknesses of your selected material can lead to a more successful project outcome.

When sourcing 304 stainless steel flat for your projects, quality is crucial. Look for suppliers that offer detailed specifications. Check the material's thickness, width, and length to ensure it meets your needs. High-quality 304 stainless steel should have a smooth finish without visible defects. A good finish can enhance both durability and appearance.

Inspect the certification of the material. Many suppliers provide certification that verifies the composition of the stainless steel. This can help you avoid low-quality products. Ask for samples if possible. Holding the material allows you to assess its weight and feel. A heavier piece often indicates better quality, but it’s not the only factor.

Be wary of pricing that seems too good to be true. Low prices can hint at inferior quality. Take your time when comparing prices and specifications. Trust your instincts. If something feels off, it probably is. Remember, investing in quality 304 stainless steel flat can save you money in the long run. A hasty decision may lead to costly mistakes later.