Leave Your Message

Choosing the right material for your needs can significantly impact both functionality and durability, especially when it comes to industrial applications. One popular option is the 316L stainless steel belt, known for its excellent corrosion resistance and strength. With various types and specifications available, selecting the best 316L stainless steel belt can appear daunting. Factors such as intended use, environmental conditions, and mechanical requirements must be thoroughly evaluated to ensure optimal performance. In this blog, we will guide you through the critical considerations and features that define the ideal 316L stainless steel belt for your specific applications, helping you make an informed decision that meets your operational needs. Whether you're in manufacturing, food processing, or another industry, understanding these nuances will be key to enhancing efficiency and longevity in your projects.

When selecting a 316L stainless steel belt for your application, understanding the properties of 316L stainless steel is crucial. This alloy is renowned for its superior corrosion resistance, especially in chloride environments, making it an ideal choice for marine, chemical, and food processing industries. The addition of molybdenum in 316L enhances its ability to withstand corrosive substances, ensuring longevity and durability even in harsh conditions.

Another significant feature of 316L stainless steel is its strength and toughness at elevated temperatures. This attribute makes it suitable for applications that experience thermal stress or require stability under heat. Moreover, 316L's lower carbon content compared to other stainless steel grades reduces the risk of carbide precipitation during welding, which is essential for maintaining the integrity of the belt in structural applications. Understanding these properties allows you to make an informed choice that aligns with the specific demands of your project, ensuring effective and efficient use of the 316L stainless steel belt.

| Property | Description | Application Suitability |

|---|---|---|

| Corrosion Resistance | Excellent resistance to pitting and crevice corrosion in chloride environments. | Ideal for marine, chemical processing, and food processing applications. |

| Temperature Resistance | Maintains strength and oxidation resistance at high temperatures. | Suitable for high-temperature industrial applications. |

| Mechanical Properties | Good tensile strength and ductility, allowing for fabrication and forming. | Valuable in stress-related applications, such as in structural components. |

| Weldability | Easy to weld using all conventional methods, minimizing the likelihood of cracking. | Used in applications requiring complex shapes and designs. |

| Magnetic Properties | Non-magnetic in the annealed condition but may become magnetic when cold-worked. | Important for applications where magnetic properties are a concern. |

| Finish Options | Available in various finishes, including polished, brushed, and matte. | Enhances aesthetic appeal and functionality for various end products. |

When selecting a 316L stainless steel belt, it is essential to consider several key factors to ensure it meets your specific needs. One crucial aspect is the material's corrosion resistance. Due to its molybdenum content, 316L stainless steel is highly resistant to pitting and crevice corrosion in chloride environments, making it an excellent choice for marine and chemical processing applications. According to industry studies, 316L can withstand temperatures up to 870°C in continuous service and even higher in intermittent exposure, contributing to its durability in extreme conditions.

Another important factor is the belt's mechanical properties. The low-cycle fatigue life of 316 stainless steel is an essential consideration for long-term use, as various environmental and operational elements can significantly affect performance. Research indicates that the fatigue life can be predicted through advanced machine learning models, allowing for better safety assessments and material lifespan evaluations in demanding applications. This predictive capability is vital for industries where reliability and safety are paramount, ensuring that the selected belt can handle the anticipated loads and stresses over time.

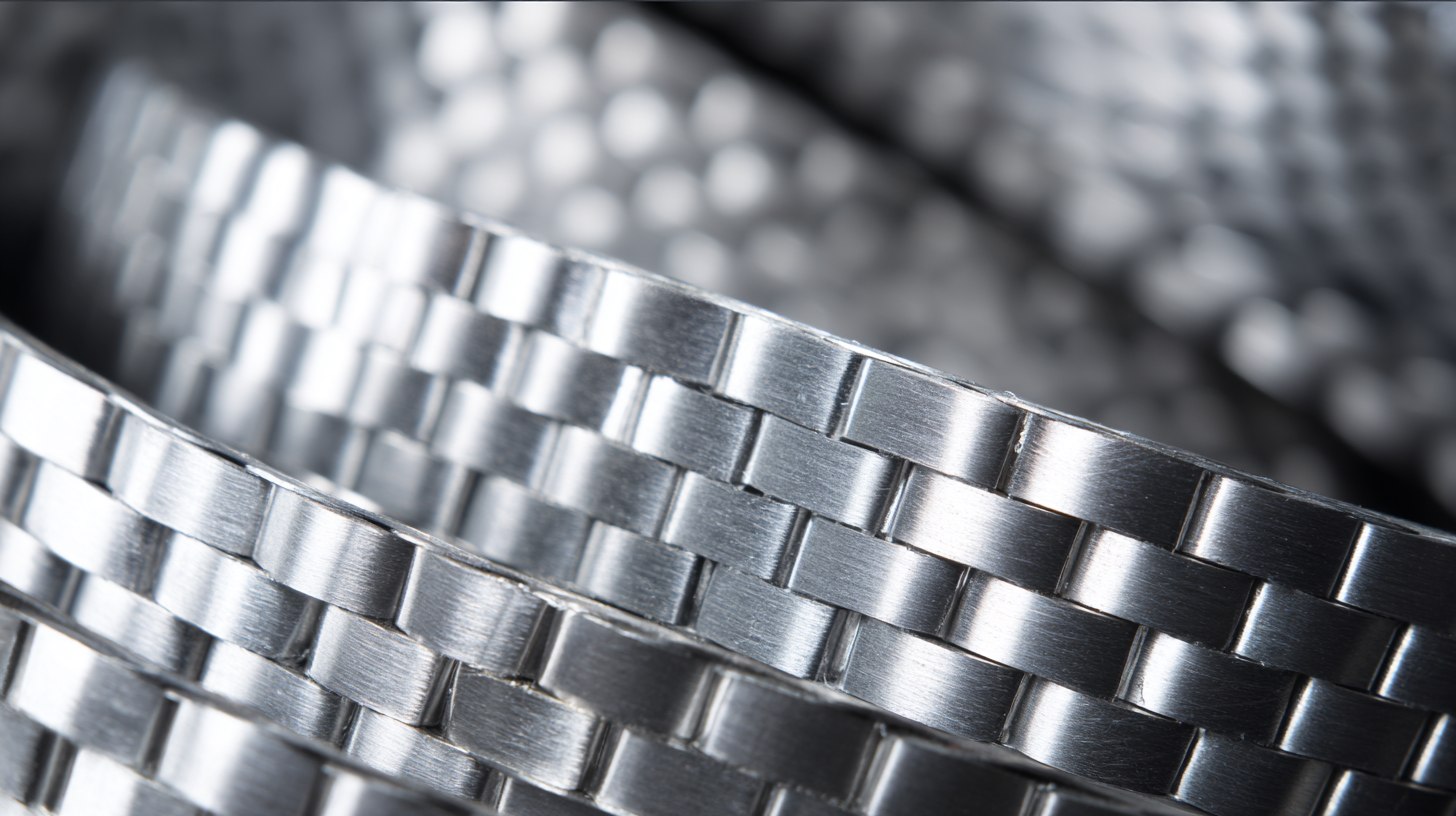

When selecting the best 316L stainless steel belt for your needs, it’s crucial to understand how it compares to other alloys commonly used in belt manufacturing.

316L stainless steel is renowned for its excellent corrosion resistance, strength, and aesthetic appeal, making it a popular choice for various applications.

Unlike standard steel or other alloys, 316L maintains its integrity in harsher environments, which is especially beneficial for belts exposed to moisture or chemicals.

This distinct advantage is further showcased in contemporary products.

For instance, some premium belt designs utilize 316L stainless steel due to its luxury appeal and durability.

In recent product launches, belts made from this alloy have been highlighted for their craftsmanship and longevity, emphasizing that quality materials like 316L not only enhance functionality but also elevate the overall aesthetic of the accessory.

As consumers increasingly seek versatile and resilient pieces, understanding the unique properties of 316L stainless steel can guide you in making an informed decision that aligns with your personal style and functional requirements.

When selecting the ideal 316L stainless steel belt for your specific applications, understanding the relevant industry standards and certifications is crucial. The 316L grade of stainless steel is renowned for its exceptional corrosion resistance and durability, making it a popular choice in various industries, including food processing, pharmaceuticals, and marine applications.

To ensure that your selected belt meets necessary safety and quality requirements, you should look for certifications such as ASTM, ASME, and ISO standards, which confirm the material's properties and manufacturing processes.

In addition to general standards, specific certifications related to hygiene and safety play a significant role. For instance, belts used in food processing must comply with FDA regulations, ensuring they are safe for direct contact with food. Certifications from organizations like NSF International can also provide additional assurance of the belt's suitability for your industry. By prioritizing these standards and certifications, you can confidently choose a 316L stainless steel belt that not only meets your operational needs but also upholds the highest quality and safety benchmarks.

When selecting the best 316L stainless steel belt, it's crucial to examine its real-world applications and case studies to understand its effectiveness and adaptability. 316L stainless steel is renowned for its excellent corrosion resistance and durability, making it ideal for industries such as food processing, pharmaceuticals, and chemical manufacturing. For instance, a food processing plant utilized 316L belts to ensure hygiene and compliance with strict safety regulations, resulting in a significant reduction in maintenance costs and contaminations.

Tips for choosing the right 316L stainless steel belt include assessing the specific application requirements, such as temperature tolerance or exposure to corrosive environments. It's also beneficial to consult case studies pertinent to your industry, as they provide insight into how similar businesses have successfully integrated these belts into their operations. Evaluating the manufacturer's reputation and warranty offers can also guide you in making an informed decision.

Another critical aspect is to consider the belt's design flexibility. A company specializing in chemical processing switched to a custom-designed 316L stainless steel belt, enhancing productivity and longevity. By carefully analyzing these factors and studying relevant case studies, you can choose a belt that not only meets your current needs but also accommodates future demands.