Leave Your Message

When it comes to demanding projects that require strength and reliability, choosing the right materials is crucial. High Performance Wire Ropes are designed to meet these rigorous demands, offering superior tensile strength, durability, and flexibility. Whether for industrial applications, construction, or marine use, selecting the right wire rope can greatly enhance the efficiency and safety of your operations. However, with a plethora of options available in the market, making an informed choice can feel overwhelming.

Understanding the various factors that contribute to the performance of wire ropes is essential. From composition and construction to the intended application, each element plays a significant role in the overall effectiveness of the rope. By focusing on the key aspects of High Performance Wire Ropes, you can ensure that your selection not only meets the immediate requirements of your project but also stands the test of time under challenging conditions.

This guide aims to provide you with the top 10 tips for selecting High Performance Wire Ropes, empowering you to make informed decisions that align with your specific project needs. With these insights, you can confidently choose a wire rope that enhances the safety and productivity of your operations, ensuring a successful outcome for all your demanding applications.

High-performance wire ropes play a critical role in a wide array of industrial applications, ranging from construction and mining to oil drilling and marine operations. Understanding their importance begins with recognizing that these ropes provide exceptional strength-to-weight ratios, which significantly enhance load handling capabilities and safety margins. According to a report by the International Wire and Cable Research Committee, the demand for high-performance wire ropes is expected to grow at a compound annual growth rate (CAGR) of 5.3% through 2025, driven by increasing infrastructure development and mining activities globally.

One of the vital factors contributing to the significance of high-performance wire ropes is their ability to withstand extreme environmental conditions and heavy wear. For instance, wire ropes designed with advanced materials such as high-carbon steel and specialized coatings show improved resistance to abrasion and corrosion, leading to longer service life. The Mining Industry Report indicates that using high-performance wire ropes can result in a 30% reduction in maintenance costs, providing substantial economic benefits over time. By investing in superior wire rope technology, projects can ensure enhanced operational efficiency and safety, pivotal for minimizing risks and meeting stringent industry standards.

When selecting wire ropes for high-performance applications, understanding the key material considerations is essential to ensure durability and efficiency. Wire ropes are typically crafted from various materials, each exhibiting different strengths and weaknesses. Steel wire ropes, for instance, are favored for their high tensile strength and resistance to wear, making them ideal for heavy-duty lifting and rigging scenarios. According to industry reports, the global steel wire rope market is projected to grow at a CAGR of 4.5% from 2021 to 2026, highlighting the increasing demand for strong and reliable materials in industries such as construction and mining.

Another critical consideration is the type of coating applied to the wire ropes. Coatings can significantly enhance resistance to corrosion and abrasion, especially in harsh environments. For example, ropes with a galvanized coating provide an extra layer of protection against rust, which is vital for projects in marine or chemical exposure settings. A report by Research and Markets indicates that the demand for corrosion-resistant wire ropes is driving innovation, with the global market expected to see advancements in material technology. Additionally, understanding wire rope constructions—such as spun versus stranded—helps in selecting the right type based on the specific load-bearing requirements and flexibility needed for particular tasks, ensuring optimal safety and performance in any project.

When it comes to selecting high-performance wire ropes for your projects, understanding load specifications is crucial. The load specification refers to the maximum load or weight that the wire rope can handle safely. Evaluating these specifications involves considering the type of loads—static, dynamic, or shock loads—that the rope will endure. Static loads are constant and do not change, while dynamic loads vary due to movement. It’s essential to select a wire rope that not only meets these parameters but also has an appropriate safety factor to accommodate unforeseen stresses.

Another important factor in evaluating load specifications is the environment in which the wire rope will be used. Factors such as temperature variations, exposure to corrosive substances, and mechanical wear can significantly impact the performance and lifespan of the wire rope. Understanding the operational conditions allows for a more informed decision on which wire rope is best suited for the task at hand. Always ensure that the chosen rope can support the maximum expected load, including any additional forces that may arise during its operation, to prioritize safety and efficiency in your projects.

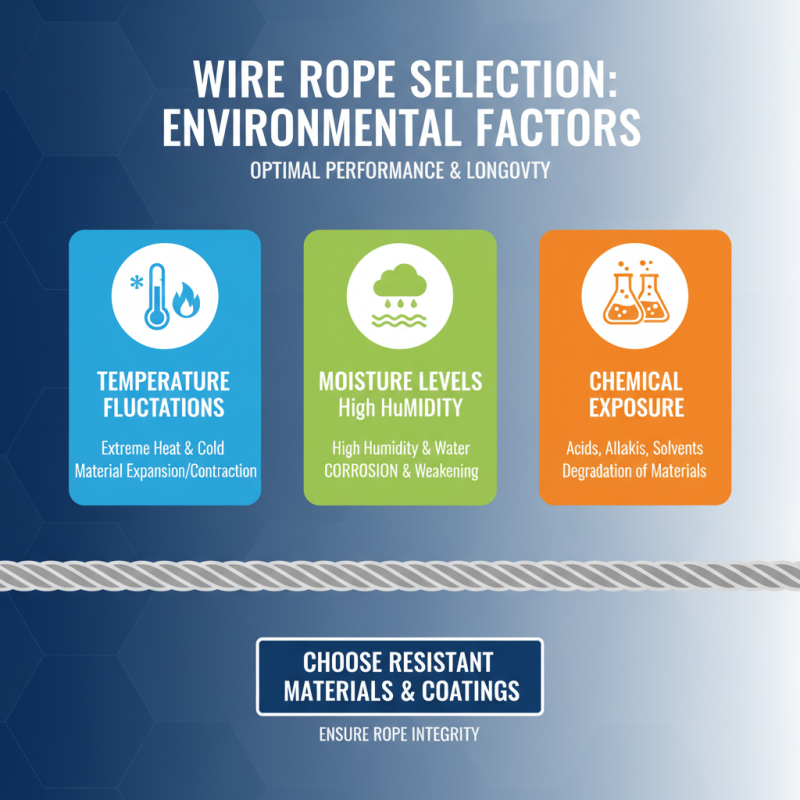

When selecting high-performance wire ropes for your projects, understanding the environmental conditions they will face is crucial for ensuring optimal performance and longevity. Factors such as temperature fluctuations, moisture levels, and exposure to chemicals can significantly impact the wire rope's integrity. For instance, high humidity or water exposure can lead to corrosion, which may weaken the rope over time. Therefore, it is essential to evaluate the specific environmental challenges your wire ropes will encounter, enabling you to choose materials and coatings that offer the best resistance to these conditions.

Moreover, the ambient temperature can influence the performance of wire ropes, especially in extreme conditions. Cold environments can make certain materials more brittle, while high heat can affect their tensile strength. Additionally, if the wire ropes are to be used in areas with heavy debris or abrasive elements, considering the mechanical wear and tear is vital. Assessing these external factors will guide you in selecting wire ropes that not only meet the strength requirements but also possess the durability needed to thrive in harsh environments, ensuring your project's success.

When selecting high-performance wire ropes for various projects, it's crucial to focus on the reputation of the manufacturer and the certifications of their products. A study from the International Wire & Cable Symposium indicates that around 78% of project failures are linked to substandard wire rope quality, underscoring the need for diligence in the selection process. Manufacturers with a solid reputation typically demonstrate consistent quality and reliability in their products. Reviewing customer feedback, industry rankings, and longstanding presence in the market can provide insights into their performance history.

Product certifications play a pivotal role in ensuring the wire rope meets safety and performance standards. Organizations such as the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) set industry benchmarks that manufacturers must adhere to. A report from the Wire Rope Association highlights that certified wire ropes have been shown to perform 20% better in tensile strength tests compared to non-certified alternatives. This data reinforces the importance of choosing wire ropes that have passed rigorous testing and hold relevant certifications, as it bolsters the assurance of safety and efficiency in demanding applications.