Leave Your Message

Choosing the right Crane Hoisting Wire Rope is crucial for any lifting project. This decision impacts safety, efficiency, and costs. Each project has specific requirements. Selecting the wrong wire rope can lead to accidents or increased downtime.

Consider factors like load capacity, environment, and lifting operations. Steel and synthetic ropes each have strengths. Steel offers durability, while synthetic ropes are lighter and more flexible. It's essential to evaluate the intended use. A wire rope mismatch may result in severe consequences.

Reflect on past experiences. Some users overlook maintenance needs. Regular inspections ensure reliability. Identify your project’s demands. The right Crane Hoisting Wire Rope not only enhances safety but also boosts productivity. Mistakes in selection often stem from inadequate research. Making an informed choice is vital.

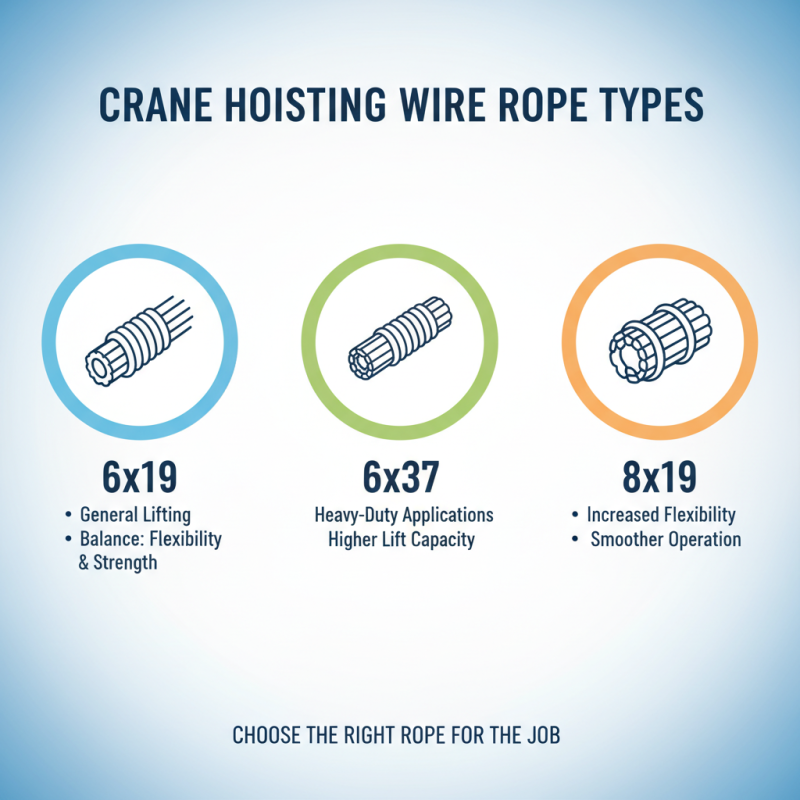

When selecting a crane hoisting wire rope, it's crucial to understand the different types available. Wire ropes vary significantly in construction and material. Common types include 6x19, 6x37, and 8x19 configurations. The 6x19 rope is widely used for general lifting, offering both flexibility and strength. In contrast, the 6x37 design provides higher lift capacities, making it suitable for heavy-duty applications.

Another essential factor is the wire rope's core material. Options like independent wire rope core (IWRC) and fiber core influence performance. IWRC enhances strength and stability, while fiber cores are lighter and more flexible. According to industry reports, engaging a wire rope with IWRC can increase service life by up to 30%. Yet, many operators overlook proper maintenance. Factors like wear, corrosion, and external conditions can significantly affect the wire rope's longevity.

Selecting the right wire rope can feel overwhelming. Many professionals face dilemmas regarding material choices and installation techniques. For example, a heavier rope might add stability but can be challenging to handle. An industry analysis noted that improper selection or use led to incidents causing over 60% of crane-related accidents. Understanding these variables is vital for safe and efficient crane operation.

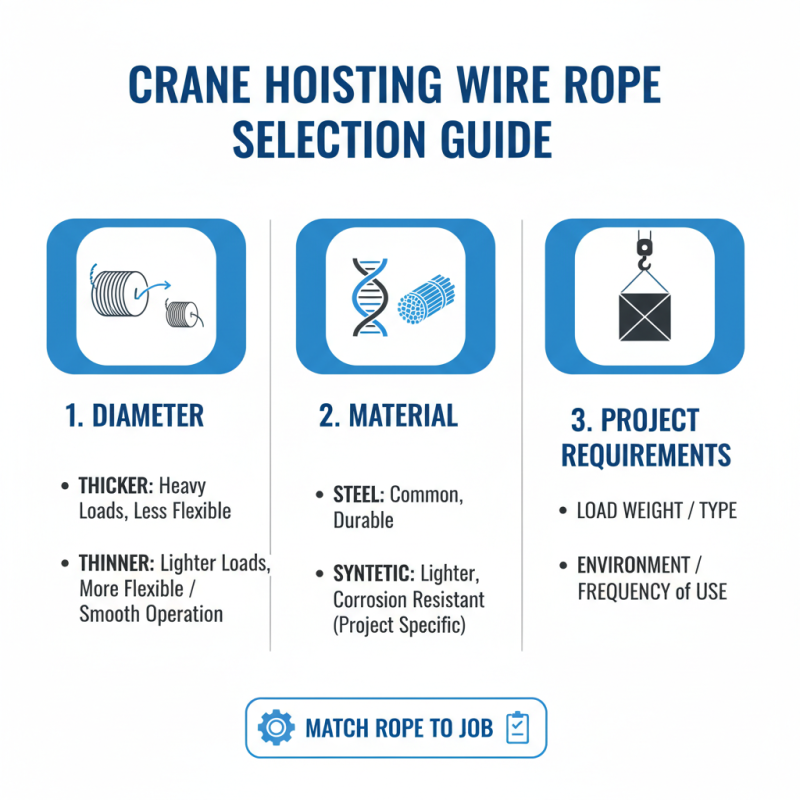

When choosing a crane hoisting wire rope, several factors are critical. The rope's diameter is crucial. Thicker ropes support heavier loads but can be less flexible. The flexibility affects how smoothly the crane operates. Also, consider the material. Steel is common, but synthetic options exist. Each has unique strengths and weaknesses, which should match your project’s requirements.

The construction of the wire rope also matters. A wire rope with a higher number of strands may provide better flexibility and resistance to fatigue. Durability is essential, especially in harsh conditions. Check for wear and tear regularly. Is the rope starting to show signs of fraying? If so, it may require immediate attention.

Environment plays a significant role in your selection. Corrosive or abrasive conditions can wear out cables quickly. Choosing the right coating can prevent damage and prolong the rope's lifespan. Reflect on your project's specific needs to ensure safety and efficiency. Each factor adds complexity to the decision-making process. Engaging with experts can provide valuable insight but make sure to weigh all options carefully.

When selecting crane hoisting wire rope, understanding load capacity is critical. Start by assessing the maximum weight your project will lift. This helps ensure safety and efficiency. Each type of wire rope has specific strength characteristics. Not all ropes are equal; some may be overkill for lighter loads. However, using a rope with too little capacity could lead to catastrophic failures.

Tip: Always calculate the safety factor. This number is essential for determining how much weight your rope can handle. A common safety factor ranges from five to ten. Knowing your safety factor can prevent overloading and enhance your project's reliability.

You might find yourself in a bind choosing between different materials and constructions. Steel wire rope often offers durability, while synthetic options provide lightweight handling. Reflect on the environment too, as corrosion resistance may be vital. Different settings change how quickly or slowly your rope wears out. Keeping track of these factors can be challenging yet crucial for longevity.

When choosing the right crane hoisting wire rope, environmental conditions play a crucial role. Factors like humidity, temperature, and exposure to chemicals can significantly affect wire rope performance. For instance, high humidity can lead to corrosion, weakening the wire over time. Meanwhile, extreme temperatures might cause the rope to become brittle or too flexible, making it less reliable.

Understanding your project's specific environmental conditions is essential. Examine the site thoroughly. Will the rope be exposed to saltwater or harsh chemicals? Such elements can accelerate degradation. Additionally, consider the frequency of use. A lesser-used rope may endure harsher environments than one subjected to daily stresses.

It's also vital to think about potential wear and tear. If your project involves abrasive materials, the rope's surface may suffer quicker damage. Real-life scenarios often reveal oversights in material selection based on conditions. Each project's unique demands highlight the need for careful evaluation. Taking the time to reflect on these details can enhance safety and performance in the long run.

Regular maintenance of crane hoisting wire ropes is essential for safe operation. Inspecting wire ropes should be done routinely. Look for signs of wear, such as broken wires or corrosion. These can indicate the rope’s remaining strength. A damaged rope can lead to dangerous situations.

Pay attention to the condition of the fittings as well. They may need inspection too. The connection points can wear out, leading to failure. Ensure you replace or repair damaged parts immediately. Record all inspections in a log. This helps track the rope's history and condition over time.

Do not ignore minor issues. They can escalate quickly. Sometimes, equipment operators may overlook small frays. But these can reduce the rope's effectiveness. Require operators to report any irregularities promptly. Creating a safe environment depends on thorough maintenance and inspection practices.

This chart illustrates the specifications for different types of crane hoisting wire ropes and their recommended inspection frequency.