Leave Your Message

Selecting the right Crane Rope Suppliers is crucial for safety in construction and industrial operations. Poor quality crane ropes can lead to catastrophic outcomes, costing organizations both financially and in terms of human safety. According to a report from the Occupational Safety and Health Administration (OSHA), improper rigging and equipment failures contribute to a significant percentage of workplace injuries.

In 2020, there were over 1,000 incidents linked to crane operations. Many of these involved faulty or substandard ropes. This highlights the importance of choosing suppliers who prioritize quality and compliance with industry standards. The risks associated with subpar equipment cannot be overstated, as they directly impact worker safety and operational efficiency.

Moreover, reliable Crane Rope Suppliers invest in rigorous testing and quality assurance. This not only ensures product longevity but also enhances the overall safety of lifting operations. Organizations must reflect on their existing partnerships and assess whether those suppliers meet safety regulations. Seeking out suppliers who uphold high safety standards can prevent potential mishaps and contribute to a safer work environment.

In construction projects, the quality of crane rope is crucial. High-quality ropes ensure safety and enhance efficiency. A recent industry report notes that over 40% of construction-related accidents involve equipment failure linked to inferior lifting materials. This underlines the need for reliable crane ropes.

The composition of crane ropes significantly affects their performance. Ropes made from premium materials can withstand greater loads and resist wear and tear. For example, steel wire ropes can endure 20% more tensile strength than lower-grade alternatives. Yet, not all suppliers meet these standards. Some prioritize cost over quality, leading to risks on site.

Choosing the right suppliers is vital. A poor choice can lead to serious consequences. Some companies overlook certification and testing protocols. This negligence can result in equipment failures and even fatalities. Investing in high-quality crane ropes is a step towards creating a safer work environment in construction, but awareness and diligence in supplier selection are equally important.

When selecting a crane rope supplier, safety is paramount. It is essential to consider various specifications. The quality of materials used is crucial. High-tensile, durable materials can greatly impact the lifespan and functionality of the ropes. Look for suppliers that prioritize these aspects in their offerings. Ropes made from synthetic fibers often provide better performance in various conditions.

Moreover, the testing standards of the ropes should not be overlooked. Ensure the supplier adheres to industry regulations. Third-party testing can also give you peace of mind. A supplier's track record speaks volumes. Consider their experience and customer feedback. Suppliers with a history of meeting safety standards are more reliable.

Don't forget about the range of products offered. A reputable supplier will have different options to match various applications. This helps in making informed decisions. However, it's important to stay vigilant and not rush into a choice. Sometimes, even the most reputed suppliers can have faults. Critical evaluation ensures a safer work environment.

| Specification | Importance | Recommended Standards |

|---|---|---|

| Material Quality | Ensures durability and resistance to wear and tear. | ISO 9001 Certification |

| Breaking Strength | Critical for load safety and operational efficiency. | Minimum 5:1 Safety Factor |

| Flexibility | Allows for easy handling and installation. | ASTM D3950 |

| Resistance to Environmental Factors | Prevents degradation in harsh conditions. | ASTM G154 for UV Resistance |

| Manufacturer Reputation | Indicators of quality and reliability. | Industry reviews and testimonials |

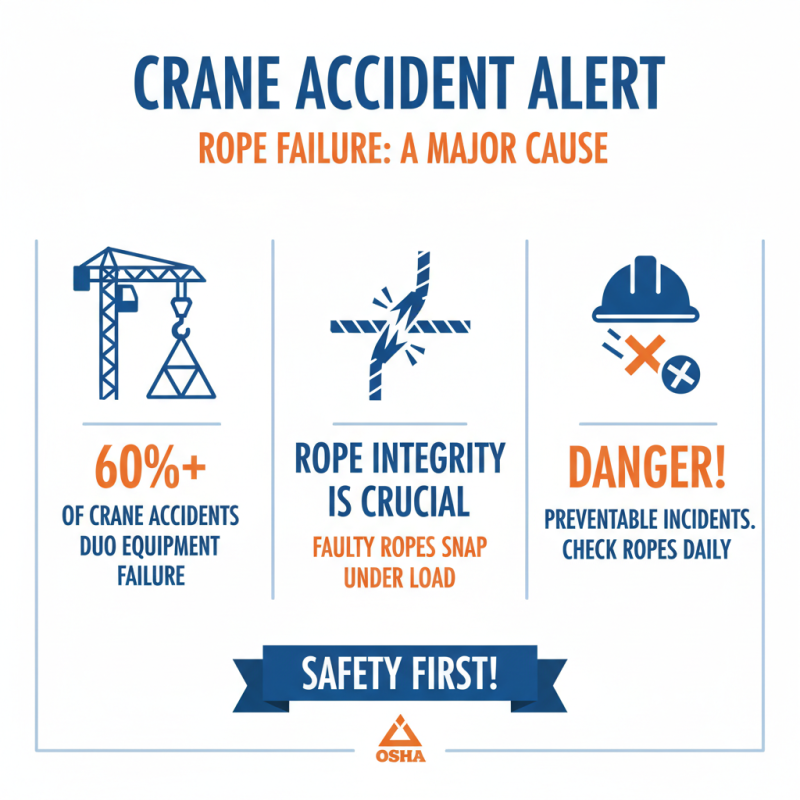

Crane accidents are alarming and often linked to rope failures. According to the Occupational Safety and Health Administration (OSHA), over 60% of crane accidents result from equipment failure. Rope integrity is crucial. Faulty or low-quality ropes can snap under load, creating dangerous situations.

In 2020, the Bureau of Labor Statistics reported that nearly 70 deaths occurred due to crane-related incidents. A significant portion of these fatalities involved rope failure. Inspecting and maintaining crane ropes can make a difference. Properly trained personnel should regularly check for wear and tear. Statistics show that more than 30% of crane accidents could be prevented with better equipment inspections and supplier reliability.

Choosing the right suppliers is essential. Not every rope is suitable for all applications. The materials used, strength ratings, and durability differ widely. A poorly chosen rope can fail unexpectedly. This leads to unnecessary risks. Investing time in selecting quality suppliers can enhance safety, reduce accidents, and save lives.

Choosing the right materials for crane ropes affects safety directly. Different ropes are made from various materials, impacting durability and performance. Many operators overlook this aspect. They may focus on cost rather than quality.

Material standards play a vital role in ensuring safety. Quality ropes need to withstand heavy loads and harsh conditions. For instance, synthetic fibers, while lightweight, may not resist abrasion as well as steel. Regular inspections are crucial. A worn-out rope can lead to catastrophic failures.

Many suppliers claim to meet certain standards. However, not all adhere strictly to safety regulations. Some materials may pass initial tests but degrade over time. Operators must ask questions. Do their ropes meet recognized safety standards? Proper research can prevent dangerous incidents. Real lives depend on these decisions.

In the crane industry, choosing the right rope suppliers is critical for safety. The qualifications and certifications of these suppliers can significantly influence operational safety. Detailed compliance with international standards, such as ISO 9001, ensures that suppliers maintain high-quality production processes. Companies adhering to such certifications report safety-related incidents 30% lower than their non-compliant counterparts.

Regular audits and assessments are vital. Research shows that 75% of crane accidents stem from equipment failure. Properly certified suppliers often implement more rigorous testing protocols. For instance, tensile strength tests can prevent catastrophic failures. However, not all suppliers invest in these crucial procedures. This raises concerns over the reliability of the ropes used, especially in high-stress environments.

Evaluating certifications is just one part of the equation. It’s essential to consider the history and reputation of the supplier. For instance, a supplier with numerous complaints may hint at compromised standards. Taking shortcuts in supplier evaluation can lead to severe ramifications. Actively seeking out suppliers with proven safety records will enhance overall operational safety.