Leave Your Message

In the realm of industrial lifting and material handling, selecting the appropriate Hoist Steel Wire Rope is critical to ensuring both safety and efficiency. According to the Global Wire Rope Market report by Research and Markets, the demand for wire ropes is projected to grow significantly, with an expected compound annual growth rate (CAGR) of 5.2% from 2021 to 2026. This underscores the importance of choosing the right material and specifications to meet the unique needs of various applications. With factors such as diameter, construction type, and environmental conditions influencing performance, understanding how to navigate these considerations can make a substantial difference in operational effectiveness. This guide aims to provide a comprehensive overview of the factors to consider when selecting Hoist Steel Wire Rope, helping you make informed decisions that promote safety and productivity in your operations.

When it comes to selecting the right hoist steel wire rope, understanding the basic types and their applications is paramount. Different environments, particularly in mining, impose varied demands on wire ropes. For instance, wire ropes in coal mines face unique challenges due to wear caused by multi-layer winding systems. This kind of application highlights the importance of rigorous wear assessments to ensure miner safety. As ropes wear, their carrying capacity decreases, making it essential to monitor their condition through advanced methods like nondestructive testing using magnetic sensors.

Moreover, the mechanical response and fracture behavior of steel wire ropes under different levels of surface wear significantly influence their performance. Research shows that surface wear is a primary factor in breaking failures, which poses serious hazards in mining operations. It is critical for operators to pay attention to the strand lay direction and crossing angle, as these factors also affect the tribological behavior of the winding ropes. By understanding these intricacies, engineers can make informed choices to enhance safety and efficiency in heavy lifting applications.

When selecting the right hoist steel wire rope, several key factors should be considered to ensure safety and efficiency in lifting operations. First and foremost, the load capacity of the wire rope must match or exceed the requirements of your specific application. It’s essential to evaluate the working load limit (WLL) and factor in any potential overload situations to avoid accidents. The diameter of the wire rope also directly influences its strength, so choosing the correct size for your hoisting equipment is crucial.

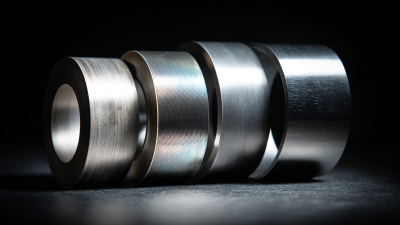

Another significant factor is the construction and material properties of the wire rope. Different types of wire ropes, such as those made from stainless steel or galvanized steel, offer varying resistance to corrosion and wear, which is vital in diverse working environments. Additionally, consider the design features, such as the number of strands and the configuration of the wires, which can impact flexibility and fatigue resistance. Furthermore, always account for adverse weather conditions, as they can critically affect both the operation and lifespan of lifting equipment. By carefully assessing these factors, you can ensure that you choose the most suitable hoist steel wire rope for your needs.

When selecting the right hoist steel wire rope, it’s essential to consider the various materials available. Each material comes with its own set of advantages and disadvantages that can significantly influence the performance and longevity of the wire rope in your application. Steel wire ropes, for instance, are known for their high tensile strength and durability, making them the go-to choice for heavy lifting. However, they come with added weight and can be prone to corrosion if not properly maintained.

On the other hand, synthetic ropes have become increasingly popular for certain applications due to their lightweight nature and resistance to environmental factors. They are easier to handle and can float on water, which is advantageous in marine settings. However, they may lack the same level of durability as steel ropes when subjected to extreme loads or heavy wear and tear. By weighing the pros and cons of each material, you can choose the hoist steel wire rope that best meets your specific needs and enhances the efficiency of your operations.

When choosing the right hoist steel wire rope, one of the most crucial aspects to consider is adhering to essential safety standards and codes. Safety regulations are put in place to ensure that the wire rope can withstand the required loads and operate effectively within its specified limits. It is imperative to consult local and international standards, such as those from the American National Standards Institute (ANSI) or the Occupational Safety and Health Administration (OSHA), to guarantee compliance and enhance workplace safety.

Tips: Always verify that the hoist wire rope is rated for the specific type of load it will be lifting. Inspect the rope regularly for any signs of wear, fraying, or damage, which could compromise safety. Additionally, make sure that the rope is properly stored and maintained following the manufacturer’s guidelines to extend its lifespan and reliability.

Recent events underscore the importance of safety in construction projects, as demonstrated by the specialized safety competition held in Shaoxing. This initiative, aimed at enhancing safety management in the transportation construction sector, highlights the necessity for rigorous safety protocols. Choosing the right hoist equipment that meets safety standards can significantly reduce the risk of accidents and ensure compliance with regulations in various projects.

| Rope Type | Diameter (mm) | Breaking Strength (kN) | Construction | Safety Standards |

|---|---|---|---|---|

| 6 x 19 | 8 | 34.4 | IWRC | ISO 4309 |

| 8 x 19 | 10 | 57.8 | IWRC | EN 12385-4 |

| 7 x 37 | 12 | 61.5 | IWRC | AS/NZS 4024.1 |

| 6 x 36 | 13 | 73.2 | IWRC | BS 302:1987 |

| 8 x 36 | 15 | 103.1 | IWRC | ISO 10425 |

When it comes to ensuring the longevity of your hoist steel wire rope, proper maintenance is key. Regular inspections should be a fundamental part of your maintenance routine. Look for signs of wear, such as fraying or kinking, which can compromise the rope's strength. Additionally, check for corrosion, especially in environments exposed to moisture or chemicals. Implement a timely replacement strategy based on the rope's condition, usage frequency, and manufacturer's guidelines to prevent unexpected failures.

When it comes to ensuring the longevity of your hoist steel wire rope, proper maintenance is key. Regular inspections should be a fundamental part of your maintenance routine. Look for signs of wear, such as fraying or kinking, which can compromise the rope's strength. Additionally, check for corrosion, especially in environments exposed to moisture or chemicals. Implement a timely replacement strategy based on the rope's condition, usage frequency, and manufacturer's guidelines to prevent unexpected failures.

Lubrication is another critical aspect of maintenance. Appropriate lubrication reduces friction between wires, minimizing wear and tear. Choose a lubricant specifically designed for wire ropes, and ensure it penetrates thoroughly to reach all areas of the rope. Remember to clean the rope before lubrication to remove any dirt or rust that could hinder its protective qualities. By establishing a routine that combines regular inspections and proper lubrication, you can significantly extend the lifespan of your hoist steel wire rope and ensure safe and efficient operation.