Leave Your Message

In the realm of construction and heavy lifting, understanding Lifting Crane Rope is vital. Industry expert John Smith emphasizes, “Choosing the right type of lifting rope ensures safety and efficiency.” Different rope types play specific roles in lifting operations. Their features dictate how they perform under varying loads and conditions.

Material matters. Steel wire ropes are strong but heavy. They can withstand high tension and wear. Synthetic ropes, on the other hand, are lightweight and flexible, which makes them easy to handle. However, these ropes may require more care and careful inspection due to potential wear.

Navigating the vast selection of Lifting Crane Rope can be daunting. Each option has its strengths and weaknesses. Reflecting on these choices is essential. Selecting the ideal rope not only impacts project efficiency—it also affects safety on site. Every lift needs to be executed with precision, and the right rope is at the heart of that equation.

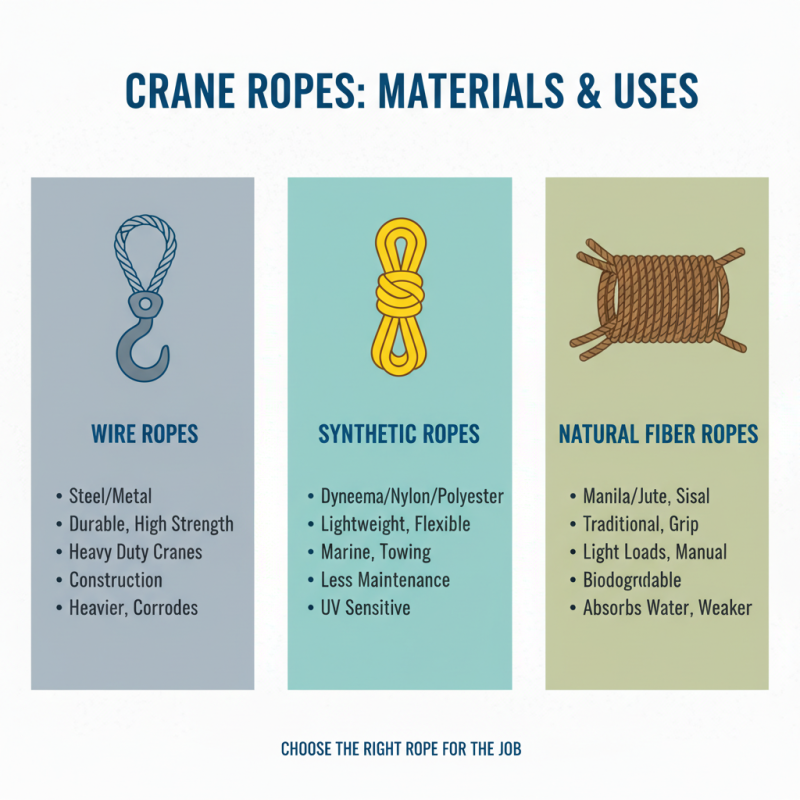

Crane ropes come in various materials, each suited for specific tasks. The most common types include wire ropes, synthetic ropes, and natural fiber ropes. Wire ropes are durable and provide high tensile strength. They are often used in heavy-duty cranes and construction sites. However, they can be heavy and require regular maintenance to prevent corrosion.

Synthetic ropes, such as those made from nylon or polyester, are lighter and more flexible. These ropes resist abrasion and can handle heavy loads efficiently. They are less likely to kink, making them user-friendly. A downside is that they may not perform well in extremely high temperatures. Natural fiber ropes, like manila, are eco-friendly but less durable. They tend to absorb moisture, leading to decay over time.

Choosing the right rope is critical. Each type has its advantages and drawbacks. Sometimes, operators may overlook maintenance. This can lead to safety hazards. It's essential to assess the operating environment and load conditions before making a decision. Ignoring such details can be costly.

Steel wire ropes are essential in lifting applications due to their strength and durability. These ropes consist of multiple individual strands, twisted together to enhance tensile strength. They are designed to withstand heavy loads, making them ideal for cranes and hoisting systems.

The applications of steel wire ropes are diverse. They are commonly used in construction sites, shipping docks, and mining operations. In each setting, safety is a primary concern. A faulty wire rope can lead to accidents and significant losses. Regular inspections and maintenance are crucial. Over time, wear and tear can affect the rope's integrity. Operators often overlook this aspect, leading to potential hazards.

Steel wire ropes come in various configurations. Some have a higher resistance to abrasion, while others focus on flexibility. Choosing the right type is vital but often complicated. It’s important to balance strength, flexibility, and the specific task at hand. Many users may not fully understand the implications of their choices. Each application poses unique challenges, and failing to recognize these can lead to costly mistakes.

| Rope Type | Material | Strength (kN) | Durability | Common Applications |

|---|---|---|---|---|

| Steel Wire Rope | Steel | 2000 | High | Construction, Shipping |

| Synthetic Rope | Nylon/Polyester | 1500 | Moderate | Maritime, Recreational |

| Compacted Steel Wire Rope | Steel | 2500 | Very High | Mining, Heavy Lifting |

| Flexible Wire Rope | Steel | 1700 | High | Cranes, Lifting |

| Wire Rope with Coating | Steel with Plastic Coating | 1800 | High | Construction, Marine |

Synthetic ropes offer significant advantages in lifting operations. They are lightweight yet strong, providing excellent tensile strength. A report from the American Society of Civil Engineers highlights that synthetic ropes can be up to 50% lighter than steel counterparts. This lightweight nature can improve handling and reduce wear on lifting equipment.

The flexibility of synthetic ropes is yet another benefit. They can adapt to various load shapes without losing strength. This adaptability is particularly useful in confined spaces or when lifting irregularly shaped loads. Synthetic ropes also have lower stretch compared to traditional materials, ensuring precise load control during lifting tasks.

However, synthetic ropes do have some limitations. They can be susceptible to damage from UV light and certain chemicals. The durability may not match that of steel in harsh environments. Regular inspections and proper storage are essential. Operators should remain aware of these factors to maximize safety and efficiency.

When selecting crane ropes for specialized applications, several detailed features play a significant role. These ropes must meet specific lifting requirements. For instance, wire ropes excel in heavy-duty lifting. They offer high tensile strength and resistance to wear. This durability is crucial for construction sites where heavy loads are frequent.

Synthetic ropes, on the other hand, can be lighter and easier to handle. They are often used in marine environments due to their resistance to corrosion. Their flexibility allows for easier knotting and splicing, which can improve usability. However, these ropes may lack the same load-bearing capacity as wire ropes, raising questions about their reliability under heavy loads.

It is essential to reflect on each rope's limitations. For example, while synthetic ropes provide safety in certain contexts, they can degrade under UV exposure. This could lead to unexpected failures. Always consider the lifting environment and the type of loads involved. Balancing these needs is crucial for operational safety and efficiency.

Proper maintenance of lifting crane ropes is critical for safety.

Regular inspections help identify wear and tear. Look for fraying, kinks, or broken strands.

These signs indicate that the rope may fail under load. Even small damage can lead to accidents.

Lubrication is essential for the longevity of crane ropes.

Use the right type of lubricant specified for the rope material. Too much lubricant can attract dirt and debris, while too little can lead to corrosion.

Balance is key here.

Storing ropes correctly also matters. Keep them in a dry, cool place to prevent moisture damage.

Bending the ropes too sharply can weaken them. Take time to reevaluate your storage methods and ensure they are effective.

Regular maintenance checks and careful storage can significantly improve safety and operational efficiency.