Leave Your Message

Elevator Steel Wire Rope is crucial in the lift industry. It ensures safety and efficiency. According to a report by the International Organization for Standardization (ISO), over 20 million elevators rely on steel wire ropes globally. David Miller, a renowned expert in the field, stated, “The reliability of Elevator Steel Wire Rope is fundamental for modern vertical transport.”

These ropes are made from high-strength steel, which contributes to their durability. They can withstand heavy loads and harsh conditions. Regular maintenance is essential. Inadequate care can lead to wear and potential failures. The expected lifespan of these ropes can vary significantly due to environmental factors and load application.

However, challenges remain in this sector. Not all providers adhere to the same quality standards. This inconsistency poses risks for elevator operation. Education and awareness about the importance of quality Elevator Steel Wire Ropes are necessary. A failure to prioritize this can have serious consequences for safety and efficiency in the lift industry.

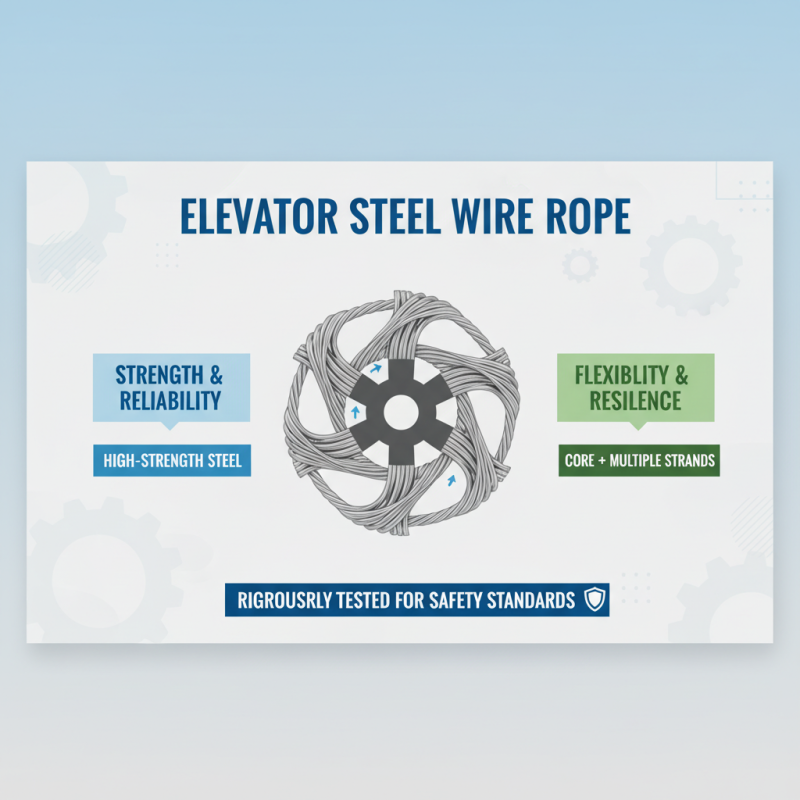

Elevator steel wire rope is a crucial component in modern lifts, providing safety and reliability. These ropes are typically made from high-strength steel, ensuring they can bear heavy loads. Their design features a core structure wrapped in multiple strands, contributing to flexibility and resilience. Often, these ropes are subjected to rigorous tests to meet safety standards.

The application of elevator steel wire rope goes beyond just lifting. They also offer excellent durability under various conditions. However, the wear and tear from daily usage can pose challenges. Regular maintenance is vital to ensure their lifespan. Over time, corrosion may occur, reducing strength. This highlights the need for inspections and timely replacements. The balance between reliability and routine upkeep can often be a point of concern for operators.

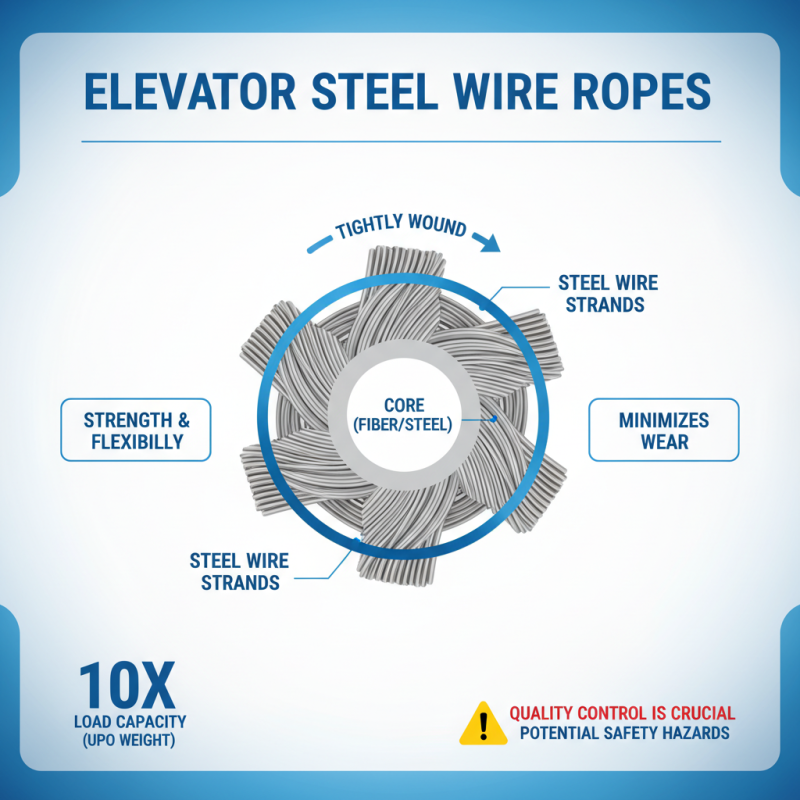

Elevator steel wire ropes are crucial components in modern lift systems. Their construction involves a core, usually made of fibers or steel, surrounded by tightly wound steel wire strands. This design enhances strength and flexibility while minimizing wear and tear. According to industry reports, a properly designed wire rope can support loads of up to 10 times its weight. However, quality control during manufacturing can vary, leading to potential safety hazards.

The design aspects of these wire ropes often highlight the need for precise engineering. Rope diameter and strand construction impact load handling significantly. For example, a thicker rope may carry heavier loads but could increase the overall weight of the lift. This weight is a critical factor in energy efficiency. Interestingly, many lift manufacturers often overlook maintenance schedules for these ropes, leading to premature failure. Regular inspections and adherence to recommended practices can mitigate these risks significantly.

Despite advancements in materials and design, the industry still faces challenges with fatigue and corrosion in wire ropes. It’s essential to note that even minor flaws in manufacturing can lead to severe consequences. Continuous research and development are necessary to improve the longevity and safety of elevator steel wire ropes. Ultimately, embracing innovation in design can revolutionize this sector while ensuring user safety remains paramount.

Elevator steel wire ropes are crucial components in lift systems. These ropes are designed to handle heavy loads and ensure safety. There are various types of steel wire ropes, each with unique specifications. A common type is the 6x19 rope, made with a total of 19 wires in six strands. It offers excellent flexibility and strength, making it popular in many elevators.

Another type is the 8x19 rope, known for its high resistance to wear. This rope supports smoother operations and can reduce maintenance needs. Steel wire ropes may come with different coatings, enhancing their durability against environmental factors. However, it’s essential to track wear over time. Regular inspections are necessary to ensure safety and performance.

Beyond these, there's the rotation-resistant rope, designed to minimize twisting. This feature is vital, especially in high-speed elevators. Yet, selecting the right type requires careful consideration of lift specifications and usage patterns. Mistakes in choosing the wrong rope can lead to performance issues. Thus, understanding each type’s advantages and limitations is critical for optimal application.

Elevator steel wire rope is essential in modern lift systems. This high-strength material offers durability and reliability. Its design typically involves multiple strands of steel wires, twisted together for enhanced strength. This construction allows the rope to withstand heavy loads and stresses during operation.

In elevators, the wire rope serves as a vital component. It connects the lift car to the hoisting mechanism. As the motor operates, the rope moves up and down, carrying passengers safely between floors. The flexibility of the wire rope allows smooth movements, which is crucial for user comfort. However, factors like wear and tear can affect its lifespan. Regular inspections are necessary to ensure safety.

Another application is in freight elevators, where the load capacities are higher. The steel wire ropes must handle larger weights without breaking. Ensuring the correct specifications is crucial here. If the rope is too weak, it can lead to accidents. All these details highlight the importance of quality materials in lift design. The balance of strength and flexibility remains a challenge in elevator engineering.

This chart illustrates the various applications of elevator steel wire rope in modern lifts, highlighting its significant roles in different lifting mechanisms.

Maintaining elevator wire ropes is crucial for safe operations. Regular inspections help detect wear and corrosion. Even small issues can lead to serious failures. Operators must check the sheaves and pulleys too. These components work closely with the wire ropes. Any misalignment can cause uneven wear.

Lubrication is often overlooked. Proper lubrication reduces friction and wear. However, too much lubricant can attract dirt. This dirt can damage the wire ropes over time. It’s important to find the right balance.

Monitoring load limits is another key factor. Overloading can compromise the integrity of the wire rope. This not only shortens its lifespan but also poses safety risks. Establishing clear weight limits is essential. Operators should also keep records of maintenance activities. These practices help ensure a safer lift environment.

| Dimension | Specification | Material | Application | Maintenance Considerations | Safety Considerations |

|---|---|---|---|---|---|

| Diameter | 6 - 20 mm | Steel | Elevator Systems | Regular inspection for wear | Load testing every year |

| Breaking Load | Up to 30 tons | Galvanized Steel | Freight Lifts | Lubrication of individual ropes | Inspect for signs of corrosion |

| Construction Type | 6x19 or 6x37 construction | Stainless Steel | Residential Elevators | Check for strand breaking | Training for elevator operators |

| Weight | 0.3 - 1.0 kg/m | High Carbon Steel | Observation Lifts | Replace every 5-10 years | Emergency stop systems |