Leave Your Message

When it comes to the safety and efficiency of vertical transportation systems, selecting the right Elevator Rope is paramount. Research indicates that a significant portion of elevator-related accidents can be attributed to the failure of load-bearing components, including ropes. According to the Elevator Industry Work Safety Initiative, improper rope selection can jeopardize both performance and safety, underscoring the necessity for meticulous evaluation during this selection process. With various materials, designs, and strengths available in the market, understanding the specific needs of your elevator system has become increasingly pivotal. This blog will delve into seven essential tips that will guide you in making an informed choice when it comes to selecting the best Elevator Rope suited for your requirements, ensuring not only compliance with industry standards but also the preservation of passenger safety and travel reliability.

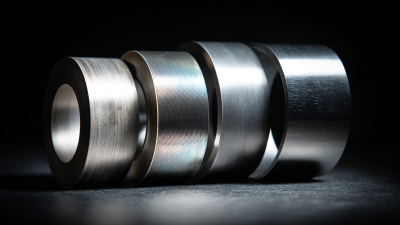

When it comes to selecting the best elevator rope, understanding the different types available and their specific applications is crucial. There are primarily two types of elevator ropes: wire ropes and synthetic ropes. According to a report by the International Association of Elevator Engineers, wire ropes dominate the market due to their durability and load-bearing capacity, making them suitable for high-rise buildings where safety and reliability are paramount. Typically, these ropes can handle loads ranging from 1,000 to 20,000 pounds, providing the necessary strength for efficiently moving elevators in skyscrapers.

On the other hand, synthetic ropes, particularly those made from materials like aramid fibers, are increasingly popular in modern elevator systems. A study conducted by the Elevator Research Consortium highlighted that these ropes offer significant advantages in weight reduction, which can improve energy efficiency in elevator operations. With a tensile strength that can reach up to 30% more than traditional wire ropes, synthetic options are ideal for applications requiring lighter systems, such as residential buildings or low-rise commercial structures. Understanding these distinctions allows builders and engineers to make informed decisions tailored to their specific elevator needs.

This chart illustrates the various types of elevator ropes and their applications in different settings. Understanding the strengths and weaknesses of each type can help in making an informed decision.

When selecting the best elevator rope materials, several key factors come into play that ensure safety, reliability, and efficiency. One of the most critical considerations is the tensile strength of the rope. A report from the American Society of Mechanical Engineers (ASME) highlights that the minimum tensile strength should exceed 32,000 psi for standard elevator applications. This high tensile strength ensures that the ropes can handle the dynamic loads imposed during operation, thereby enhancing overall safety.

Additionally, the type of material used in the construction of the elevator rope can significantly affect its performance and lifespan. According to a study by the International Association of Elevator Engineers (IAEE), steel ropes tend to last longer and provide better resistance to wear and tear compared to synthetic alternatives. However, advancements in composite materials mean that options like wire-rope strands with polyamide coatings can offer both flexibility and durability. The right choice depends on various factors, including the elevator's design, load capacity, and the environmental conditions in which the elevator operates, making thorough material evaluation essential for optimal selection.

When selecting the best elevator rope for your needs, it is crucial to assess the weight capacity and load requirements. According to industry standards, the maximum load capacity for elevator ropes varies based on material and design. For instance, steel ropes typically have a higher tensile strength, making them suitable for heavy loads, whereas synthetic options may be preferred for lighter weights. The importance of understanding your specific load requirements cannot be overstated, especially in scenarios where bariatric transport is necessary. Coordinating with specialized lifting agencies may be essential to ensure safe handling of heavier loads, particularly when considering the unique dynamics of bariatric patients.

Recent studies highlight the significance of safety in load management. For example, proof load testing has become vital for assessing the structural integrity of infrastructure such as bridges and elevators. The National Highways' assessment of the M48 Severn Bridge's main cable demonstrates the need for stringent weight restrictions based on capacity evaluations. Such assessments provide critical data that aid in making informed decisions about load limits for various lifting devices. Additionally, research on the modeling and simulation of elevator systems indicates that thorough design processes enhance operational safety and effectiveness, ensuring that your selected rope can safely handle the required capacities.

| Rope Type | Weight Capacity (lbs) | Load Requirements | Recommended Use | Material |

|---|---|---|---|---|

| Steel Wire Rope | 4500 | Heavy-duty elevators | Freight Elevators | Steel |

| Synthetic Rope | 2000 | Medium load capacity | Passenger Elevators | Polyester |

| Braided Rope | 3000 | General-purpose elevators | Service Elevators | Nylon |

| High-Performance Rope | 5000 | High-speed elevators | Luxury Elevators | Aramid Fiber |

When selecting the best elevator rope, durability and maintenance needs are paramount. High-quality elevator ropes must withstand significant wear and tear, particularly in high-traffic environments. Look for materials that are designed to resist corrosion and fatigue, ensuring longevity and reliable performance. Steel wires, for instance, are commonly used for their strength, but modern synthetic options could provide enhanced durability while being lighter and easier to manage.

Regular maintenance is essential for ensuring the longevity and safety of elevator ropes. Schedule routine inspections to assess wear and tear, as well as to check for any lubricant degradation. Also, keep an eye on the alignment of the ropes; misalignment can lead to uneven wear and potentially catastrophic failure. Consider tips such as investing in ropes with a maintenance-friendly design, which allows for easy access for inspection and replacement. Choosing the right materials and adhering to a strict maintenance schedule will help avert costly downtime and ensure smooth elevator operation.

When selecting elevator rope, balancing cost and quality is crucial for long-term performance and safety. According to a report by the National Elevator Industry, the average lifespan of elevator ropes is approximately 10 to 15 years, depending on their usage and maintenance. Investing in high-quality materials can significantly extend this lifespan, minimizing operational disruptions and replacement costs. For instance, fiber ropes, which offer lighter weights and higher flexibility, can be more expensive upfront but may reduce energy costs by up to 20% over time due to their efficiency.

When selecting elevator rope, balancing cost and quality is crucial for long-term performance and safety. According to a report by the National Elevator Industry, the average lifespan of elevator ropes is approximately 10 to 15 years, depending on their usage and maintenance. Investing in high-quality materials can significantly extend this lifespan, minimizing operational disruptions and replacement costs. For instance, fiber ropes, which offer lighter weights and higher flexibility, can be more expensive upfront but may reduce energy costs by up to 20% over time due to their efficiency.

Moreover, understanding the nuances between different rope materials is essential in making the right investment. A study by the International Organization for Standardization (ISO) indicates that elevator ropes made from high-strength steel cables can withstand greater loads and stresses compared to their synthetic counterparts. While these steel cables might present a higher initial purchase price, their durability and reduced need for replacements can lead to substantial savings over the rope’s lifecycle. Thus, focusing on quality, rather than solely on initial cost, will yield greater value and safety in the long run.