Leave Your Message

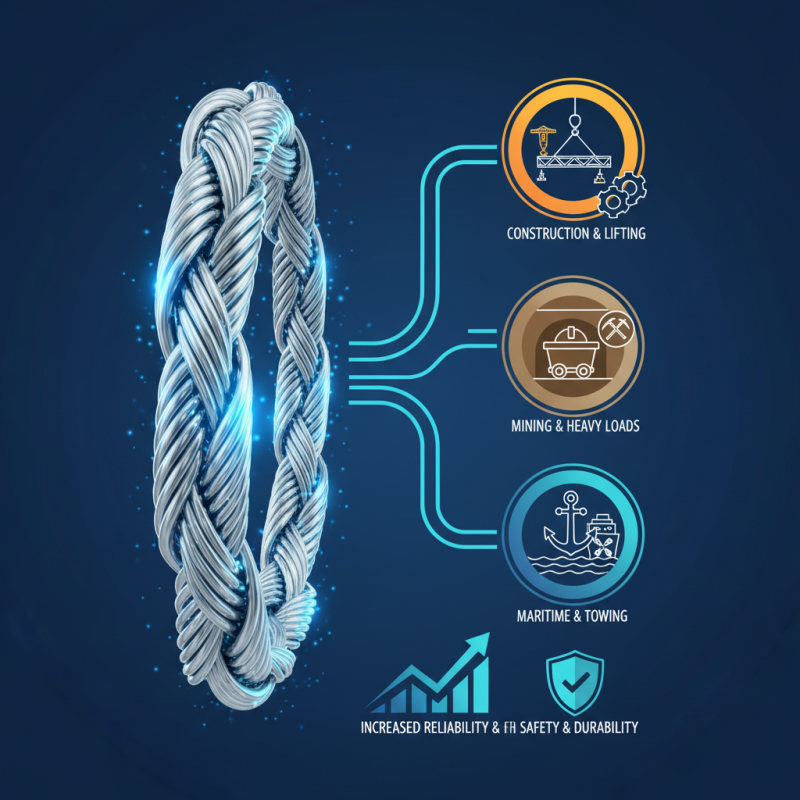

In the realm of heavy-duty applications, the choice of materials often dictates the success of operations in industries such as construction, mining, and maritime activities. Among these essential materials, High Performance Wire Ropes stand out as a pivotal component that significantly enhances the reliability and efficiency of various heavy-duty endeavors. Designed to endure extreme conditions and heavy loads, these wire ropes provide unparalleled strength, flexibility, and resistance to wear and tear.

The importance of High Performance Wire Ropes cannot be overstated; their advanced construction techniques and superior materials make them indispensable for ensuring safety and operational effectiveness in challenging environments. These wire ropes not only contribute to the structural integrity of lifting and towing systems but also minimize the risk of failure that could lead to catastrophic incidents. As industries continue to push the limits of performance, the demand for reliable and robust solutions like High Performance Wire Ropes is expected to grow, making them a fundamental aspect of modern engineering and construction projects.

Ultimately, understanding the role of High Performance Wire Ropes in heavy-duty applications is crucial for industry professionals seeking to enhance productivity while prioritizing safety and reliability. As technology advances, the development of even more resilient wire ropes will undoubtedly play a key role in shaping the future of heavy-duty operations.

High-performance wire ropes are critical components in heavy-duty applications across various industries, including construction, mining, and offshore operations. According to a report by the International Association of Oil & Gas Producers, more than 50% of offshore lifting incidents are linked to equipment failure, often involving substandard wire ropes. This highlights the importance of utilizing wire ropes that are engineered to withstand extreme stress and environmental conditions. High-performance wire ropes are designed with specific materials and construction techniques that enhance their strength, durability, and resistance to wear, allowing them to perform reliably under immense loads.

The American Society for Testing and Materials (ASTM) underscores that heavy-duty operations often require wire ropes that can maintain their integrity under cyclic loading and harsh conditions. Precision manufacturing processes have led to advancements in wire rope technology, enabling them to achieve higher tensile strengths—some reaching up to 2000 MPa. This capability is essential not just for safety, but also for operational efficiency, as downtime caused by equipment failure can result in significant financial losses, often estimated at over $200,000 per hour in major industrial settings. Therefore, investing in high-performance wire ropes is not just a matter of compliance; it’s a strategic decision that can enhance productivity while minimizing risks in heavy-duty applications.

| Application | Wire Rope Type | Diameter (mm) | Breaking Load (kN) | Uses |

|---|---|---|---|---|

| Construction | 6x19 | 16 | 80 | Lifting, Hoisting |

| Mining | 6x36 | 24 | 200 | Material Handling |

| Marine | 7x19 | 20 | 150 | Mooring, Towing |

| Industrial | Single Rope | 15 | 110 | Crane Operations |

| Forestry | 8x19 | 18 | 95 | Logging, Lifting |

High performance wire ropes are crucial for heavy-duty applications due to their unique properties that enable them to withstand extreme conditions. One of the primary characteristics that set these ropes apart is their high tensile strength, which is essential for lifting and hoisting heavy loads. According to the International Organization for Standardization (ISO), high-performance wire ropes can achieve tensile strengths exceeding 2000 MPa, significantly outperforming standard ropes.

This level of strength ensures that these ropes remain reliable even in industries such as construction, mining, and marine operations, where safety and durability are of utmost importance.

Another key property of high-performance wire ropes is their resistance to wear and corrosion. Given that many heavy-duty applications occur in harsh environments, such as underwater or in extreme temperatures, these ropes are often manufactured using specialized materials that enhance their durability. For example, studies published in the Journal of Materials Science report that wire ropes with advanced coatings can exhibit up to 300% greater lifespan compared to untreated ropes.

Additionally, high-performance wire ropes often feature improved fatigue resistance, which is vital when dealing with repetitive loads. This combination of strength, wear resistance, and fatigue durability makes high-performance wire ropes indispensable for ensuring the safety and efficiency of heavy-duty applications in challenging conditions.

In heavy-duty applications, the performance of wire ropes is paramount, with industry standards and certifications playing a critical role in ensuring safety and reliability. Organizations such as the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO) set rigorous guidelines for wire rope manufacturing, testing, and performance metrics. For instance, ISO 4309 outlines the requirements for the care and maintenance of wire ropes, emphasizing that proper adherence to these standards can significantly enhance the lifespan and safety features of the wire ropes in demanding environments.

According to a report published by the Wire Rope Technical Board, wire ropes that meet or exceed the specified industry standards show a marked increase in load-bearing capacity, resistance to abrasion, and reduced elongation under load. This performance upgrade is crucial in industries such as construction, mining, and marine, where equipment failures can lead to catastrophic accidents.

Tips: When selecting wire ropes for heavy-duty applications, always check for compliance with relevant industry standards. Regular inspections and maintenance, as outlined in the ANSI/ASME B30.2 standard, can prevent unexpected failures and extend service life. It's essential to keep detailed records of compliance certifications and maintenance logs to ensure ongoing safety and performance efficiency.

When comparing traditional wire ropes to high-performance wire ropes, several critical factors emerge that highlight the advantages of modern technology. Traditional wire ropes, while still commonly used, often fall short in terms of tensile strength, flexibility, and longevity. Made from conventional materials and with traditional manufacturing techniques, they may wear out faster and require more frequent replacements, leading to increased downtime and higher maintenance costs in heavy-duty applications.

In contrast, high-performance wire ropes are engineered with advanced materials and construction methods that enhance their load-carrying capacity and resistance to wear and environmental factors. These ropes often feature improved designs that reduce weight while maintaining strength, allowing for easier handling and installation. Additionally, they offer superior fatigue resistance, making them more suitable for repetitive lifting and pulling tasks typical in industries such as construction, mining, and marine operations. The investment in high-performance wire ropes thus translates into greater operational efficiency, safety, and overall cost savings in the long run, making them an essential choice for demanding applications.

High performance wire ropes are crucial in heavy-duty applications, providing the necessary strength and durability required for demanding environments. Industries such as construction, mining, and transportation rely on these ropes to ensure the safety and efficiency of their operations. According to a report by the International Wire and Cable Partnership, high-performance wire ropes can withstand tensile loads up to 10 times more than traditional ropes, making them indispensable in scenarios where reliability is paramount.

For instance, in the mining sector, a case study involving a major gold mine revealed that utilizing high-performance wire ropes in their hoisting systems reduced operational downtime by 30%. This increase in efficiency correlates directly with the enhanced fatigue resistance of these ropes, which are engineered to endure harsh conditions. Similarly, in construction, one project highlighted the success of wire rope slings in lifting heavy structural components. The use of advanced wire rope technology allowed for safe and precise placement, minimizing the risk of accidents and ensuring compliance with safety regulations.

These real-world applications underscore the importance of high performance wire ropes in handling extreme loads while maintaining operational integrity. Industry data suggests that adopting advanced wire rope solutions can lead to significant cost savings over time, particularly through reduced maintenance and replacement needs, emphasizing the value of investing in superior materials for heavy-duty tasks.