Leave Your Message

High Tensile Crane Rope plays a pivotal role in ensuring the safety and efficiency of heavy lifting operations across various industries. With the demand for heavy lifting capacity increasing globally, a recent report from the International Crane Safety Association indicates that crane-related incidents can be significantly mitigated through the use of high-quality materials such as high tensile ropes. These ropes are designed to withstand the enormous stress and strain encountered during heavy lifting tasks, reducing the likelihood of equipment failure and enhancing overall operational safety.

Moreover, the construction and logistics sectors are projected to experience sustained growth, with the global market for crane equipment expected to reach $13 billion by 2026, according to a market analysis by XYZ Research. Within this context, high tensile crane rope emerges as a critical component, not only improving the versatility of lifting operations but also ensuring compliance with safety standards. As industries strive to maximize productivity while minimizing risks, investing in high tensile crane rope becomes essential for businesses looking to maintain a competitive edge in their heavy lifting operations.

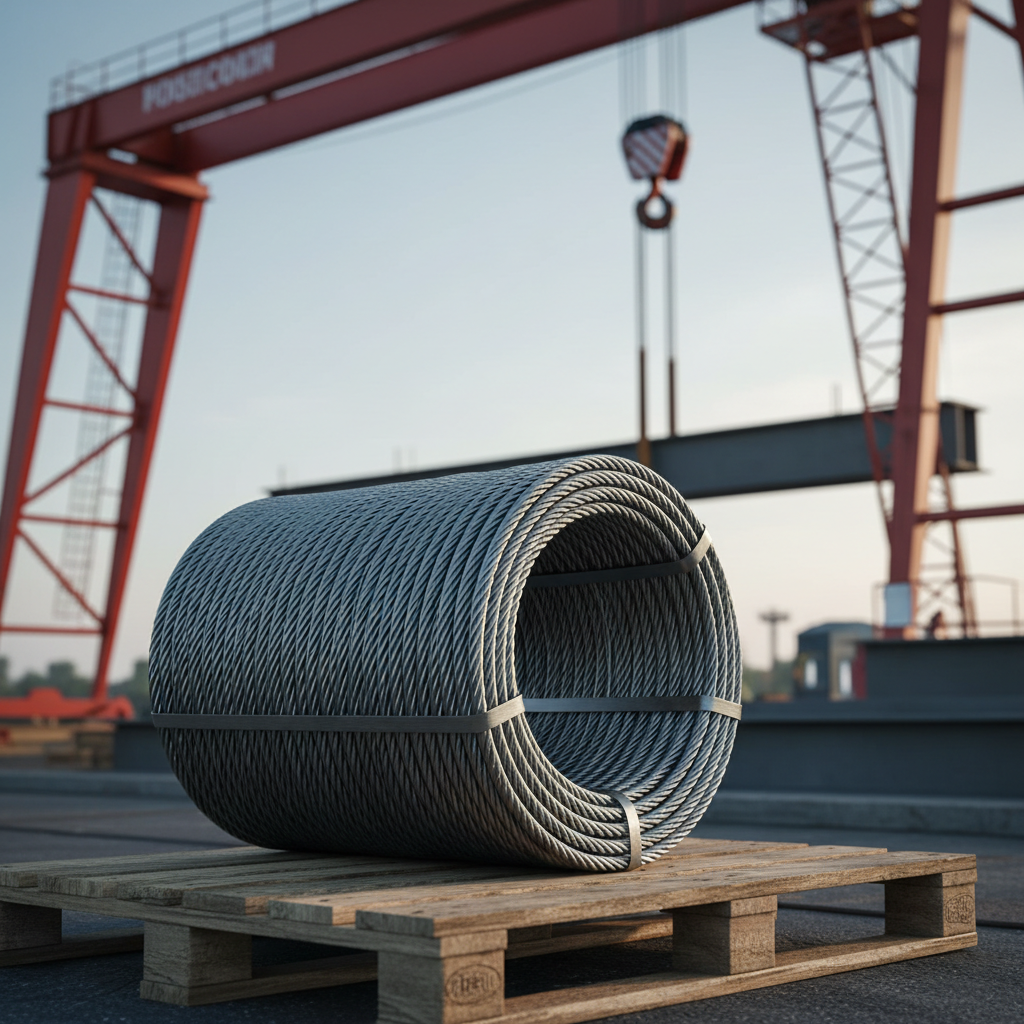

Crane ropes play an integral role in heavy lifting operations, acting as the vital link between the crane and the load. The strength and durability of high tensile crane ropes are essential for ensuring safety and efficiency during operations that often involve substantial weights. With the steel wire rope market projected to reach USD 13.88 billion by 2030, the demand for robust crane ropes showcases their significance within various industries. Properly maintained crane rope reduces the risks of accidents and failures, which can lead to costly downtime and jeopardize worker safety.

The Lifting Operations and Lifting Equipment Regulations (LOLER) emphasize the critical need for stringent inspection and adherence to safety standards, ensuring that equipment like crane ropes are regularly assessed for wear and tear. Common failures identified during LOLER inspections highlight potential weak points, stressing the importance of using high-quality materials and performing routine checks. As heavy lifting operations continue to grow, maintaining the integrity of crane rope systems is paramount, ultimately contributing to safer work environments and more efficient operations.

High tensile crane rope is crucial in heavy lifting operations due to its exceptional strength and durability. Understanding the properties of high tensile crane rope helps operators make informed decisions that enhance safety and efficiency on the job site. These ropes are specifically engineered to withstand the intense stresses involved in lifting heavy loads, ensuring minimal elongation and maximum performance under pressure. The use of high tensile materials, such as steel or advanced synthetic fibers, results in a rope that not only meets but exceeds the industry's strict safety standards.

Tips: When selecting crane ropes, consider the application and load requirements. High tensile ropes reduce the risk of breakage, providing a safety margin that is especially vital in critical lifting tasks. Additionally, regular inspections and maintenance of the cable can prolong its lifespan and maintain optimal performance. Investing in high-quality ropes ultimately leads to improved operational efficiency and reduced downtime.

High tensile crane rope plays a vital role in heavy lifting operations, delivering unparalleled strength and durability essential for demanding tasks. The advantages of high tensile materials extend beyond mere strength; they enhance overall operational efficiency and safety. According to a report by the Occupational Safety and Health Administration (OSHA), improper rope usage accounts for over 30% of crane-related accidents. By employing high tensile ropes, which can support loads up to 10 times greater than conventional alternatives, the risk of failure during lifting operations is significantly reduced.

In addition to their superior strength, high tensile crane ropes are also designed to withstand extreme conditions, including abrasion, corrosion, and temperature fluctuations. A study conducted by the American Society of Mechanical Engineers (ASME) highlights that materials like synthetic fibers and high-carbon steel increase the service life of crane ropes by up to 50%. This longevity not only reduces maintenance costs but also minimizes downtime, allowing for more efficient project timelines. Thus, integrating high tensile materials into crane operations not only enhances safety but also contributes to overall productivity and cost-effectiveness in heavy lifting scenarios.

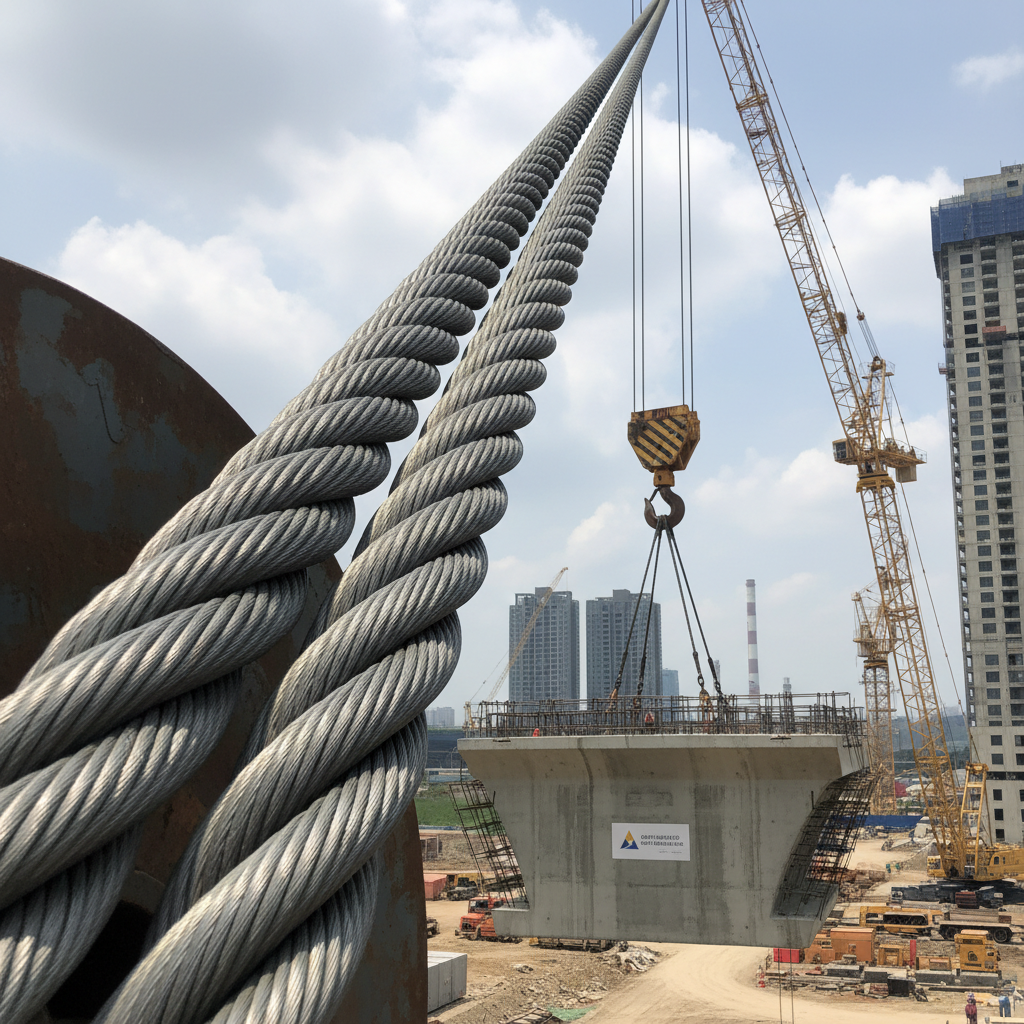

High tensile crane rope plays a pivotal role in heavy lifting operations across various industries, serving as a vital component in crane systems due to its enhanced strength and durability. In construction, for example, high tensile ropes facilitate the safe lifting of immense loads, thanks to their ability to withstand high stress and dynamic loads. The global steel wire rope market is projected to reach USD 13.88 billion by 2030, underscoring the increasing demand for robust lifting solutions in sectors that require precision and reliability.

Additionally, high tensile crane ropes find applications in industries such as marine and offshore, where they are essential for hoisting equipment and anchors securely. The synthetic rope market is also set to experience significant growth, projected to expand from USD 1.77 billion in 2025 to USD 3.04 billion by 2033. This trend reflects a growing preference for lightweight and corrosion-resistant materials that can enhance operational efficiency. The robust features of high tensile ropes contribute to safety and productivity, ensuring that heavy lifting operations can be conducted with confidence across diverse industrial environments.

When it comes to heavy lifting operations, using high tensile crane rope is paramount for ensuring safety. The structural integrity and strength of high tensile wire ropes allow them to handle substantial weights while minimizing the risk of snapping or failure during operations. This is essential in environments where large loads are constantly lifted and moved, such as construction sites, shipyards, and offshore platforms. The market for steel wire ropes is projected to grow significantly, highlighting the increasing demand for reliable and durable lifting equipment.

Safety considerations extend beyond merely selecting the right rope; they encompass rigorous monitoring and maintenance protocols. Heavy lift operations demand constant vigilance over both the equipment and the environment. Regular inspections for wear, corrosion, and other potential failures are necessary to prevent accidents. Furthermore, understanding the limitations of the crane rope, such as its maximum load capacity and environmental factors that might weaken its performance, is crucial. As the heavy lifting industry expands, prioritizing safety through high tensile crane ropes will remain a critical focus to protect both personnel and cargo.