Leave Your Message

In the construction and heavy lifting industries, safety and efficiency are paramount. Recent studies highlight the critical role that advanced materials play in enhancing operational performance. One such innovation is "High Tensile Crane Rope," which has been shown to significantly increase load capacity while minimizing the risk of accidents. According to a report by the International Association of Crane Operators, utilizing high tensile materials can reduce the incidence of crane failures by up to 30%, leading to safer work environments. Furthermore, high tensile crane ropes exhibit superior tensile strength, which not only allows for handling heavier loads but also extends the lifespan of lifting equipment. As the demand for safety and efficiency in heavy lifting continues to grow, the adoption of high tensile crane ropes represents a strategic advancement in the industry, promising enhanced productivity and risk management.

High tensile crane rope offers significant benefits when it comes to enhancing workplace safety. One of the most critical aspects of safety in any lifting operation is the strength of the equipment being used. High tensile crane ropes are engineered to withstand greater loads compared to standard ropes, reducing the risk of breakage under stress. This increased strength means that operators can perform heavy lifts with confidence, thereby minimizing accidents and injuries associated with equipment failure.

High tensile crane rope offers significant benefits when it comes to enhancing workplace safety. One of the most critical aspects of safety in any lifting operation is the strength of the equipment being used. High tensile crane ropes are engineered to withstand greater loads compared to standard ropes, reducing the risk of breakage under stress. This increased strength means that operators can perform heavy lifts with confidence, thereby minimizing accidents and injuries associated with equipment failure.

In addition to their strength, high tensile crane ropes are designed to be more resistant to wear and tear. Their durability ensures that they maintain their integrity over time, even in harsh working environments. This translates to longer service life and less frequent replacements, allowing teams to focus on their tasks without undue interruptions. Furthermore, the lightweight nature of high tensile ropes facilitates easier handling, which is crucial for maintaining safety during rigging and maneuvering operations. By adopting high tensile crane ropes, workplaces can foster a culture of safety while enhancing the efficiency of their operations.

High tensile crane ropes are revolutionizing the lifting industry by significantly enhancing load capacity and overall operational efficiency. According to a recent industry report by the Crane Manufacturers Association of America (CMAA), utilizing high tensile material can increase the breaking strength of crane ropes by up to 30% compared to traditional options. This remarkable improvement allows cranes to lift heavier loads without risking equipment failure, which is crucial in sectors ranging from construction to manufacturing.

Furthermore, the lightweight nature of high tensile crane ropes allows for better maneuverability and reduced wear on rigging components. A study by the International Society of Crane and Lifting Engineers (ISCLE) found that cranes fitted with high tensile ropes experienced 20% less strain on their hoist systems, contributing to longer service life and reduced maintenance costs. By reducing the average weight of rigging while maintaining superior strength, operators can also maximize their lifting capabilities without compromising safety, which is paramount in high-stakes work environments.

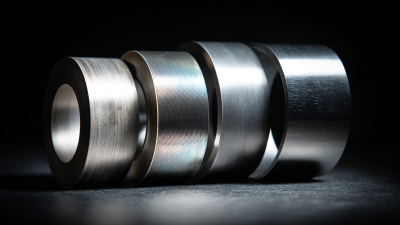

This chart illustrates the advantages of using high tensile crane rope in terms of load capacity, safety factor, weight reduction, and durability, showcasing how it enhances safety and efficiency in lifting operations.

High tensile crane rope is rapidly becoming the preferred choice in lifting operations, not just for its strength but also for its remarkable ability to reduce maintenance costs. Traditional crane ropes often require frequent inspections and replacements due to wear and tear, leading to significant downtime and unnecessary expenses. In contrast, high tensile ropes are designed to withstand greater loads and harsh environmental conditions, allowing them to maintain their integrity for a longer period. This durability translates to less frequent replacements and lower overall maintenance efforts.

Moreover, the improved efficiency that high tensile crane ropes bring to lifting operations directly contributes to decreased maintenance costs. With enhanced load handling capabilities, these ropes minimize the risk of accidental breakage and the consequential damages that might occur. Operators can conduct their tasks with greater confidence, knowing that the equipment is reliable and requires less oversight. As a result, businesses can allocate resources more effectively, focusing on productivity rather than on managing rope-related issues. Investing in high tensile crane rope ultimately leads to not just immediate savings but also long-term operational efficiency.

Advanced rope technology has revolutionized the construction and industrial sectors, significantly improving operational efficiency. High tensile crane ropes, designed with cutting-edge materials and engineering techniques, offer superior strength and reduced weight compared to traditional ropes. This combination allows cranes to lift heavier loads without compromising safety or performance, ultimately streamlining workflows and reducing downtime. Operators can rely on these advanced ropes to perform consistently under the most demanding conditions, enhancing overall productivity.

Furthermore, the durability of high tensile crane ropes reduces wear and tear, diminishing the frequency of replacements and maintenance. This translates to lower operational costs and minimized disruption to projects. The ropes’ enhanced resistance to environmental factors, such as abrasion and corrosion, ensures longevity and reliability, which are crucial in demanding workspaces. By prioritizing advanced rope technology, companies not only bolster safety protocols—reducing the risk of accidents and fostering a secure work environment—but also gain a competitive edge through optimized efficiency and reduced operational expenditures.

When it comes to crane operations, the choice of rope is crucial for ensuring both safety and efficiency. High tensile crane ropes are engineered to endure extreme loads while maintaining their structural integrity. One of the most significant advantages of these ropes is their longer lifespan, which directly impacts safety protocols on sites. With a prolonged operational life, high tensile ropes reduce the frequency of replacements, minimizing the risk of human error during installation and the potential for accidents associated with frayed or weak ropes.

Moreover, a longer lifespan translates to less downtime for equipment maintenance and fewer interruptions in workflow. This efficiency is critical in industrial settings where time is money. By relying on durable high tensile crane ropes, operators can enhance the overall safety of their teams. The reduced likelihood of rope failure means that workers can perform their tasks with greater confidence, knowing they are supported by equipment designed to withstand the rigors of heavy lifting. As a result, companies can achieve not only a safer work environment but also improved productivity, making high tensile crane ropes a smart investment for any operation relying on lifting equipment.