Leave Your Message

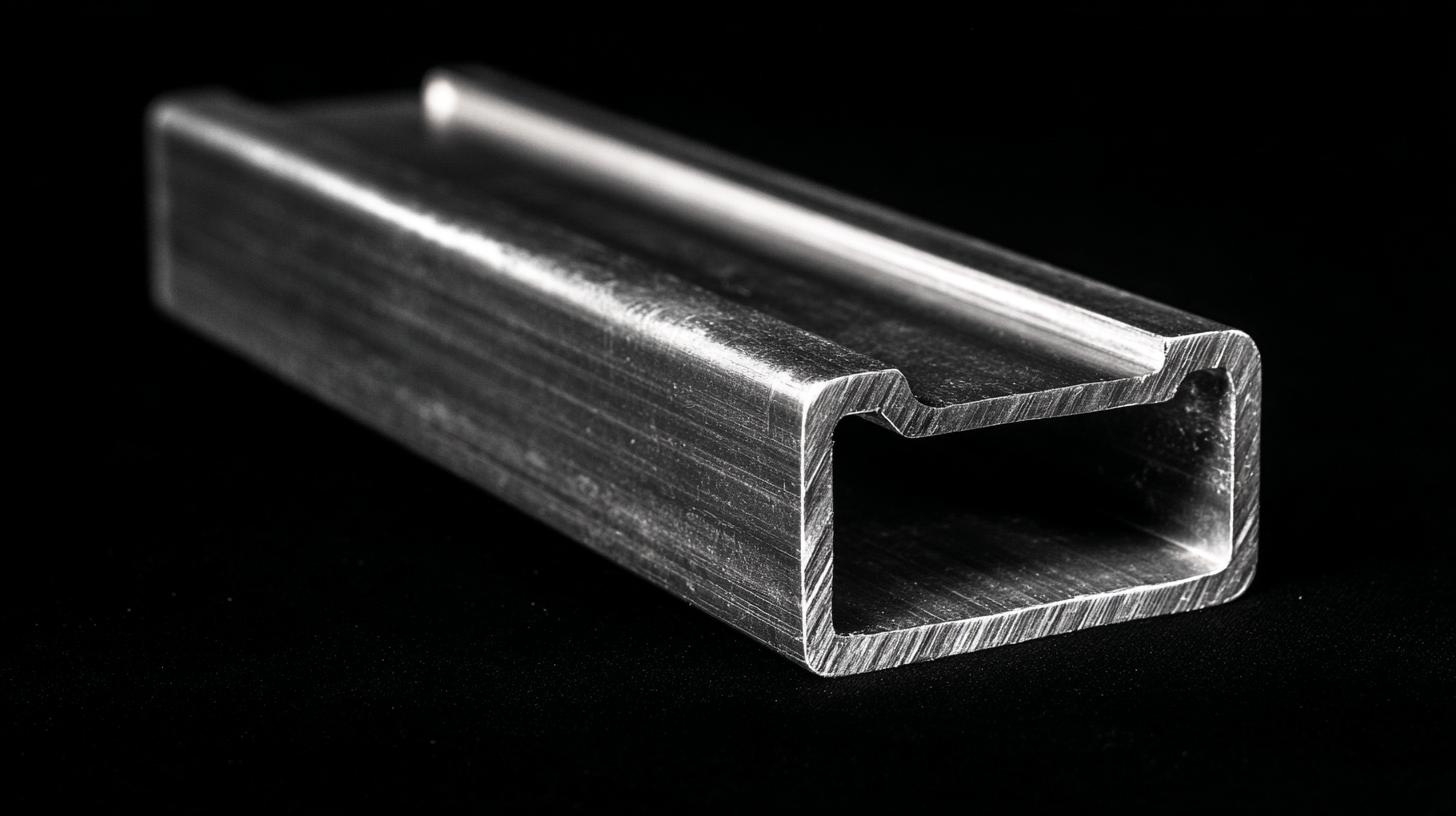

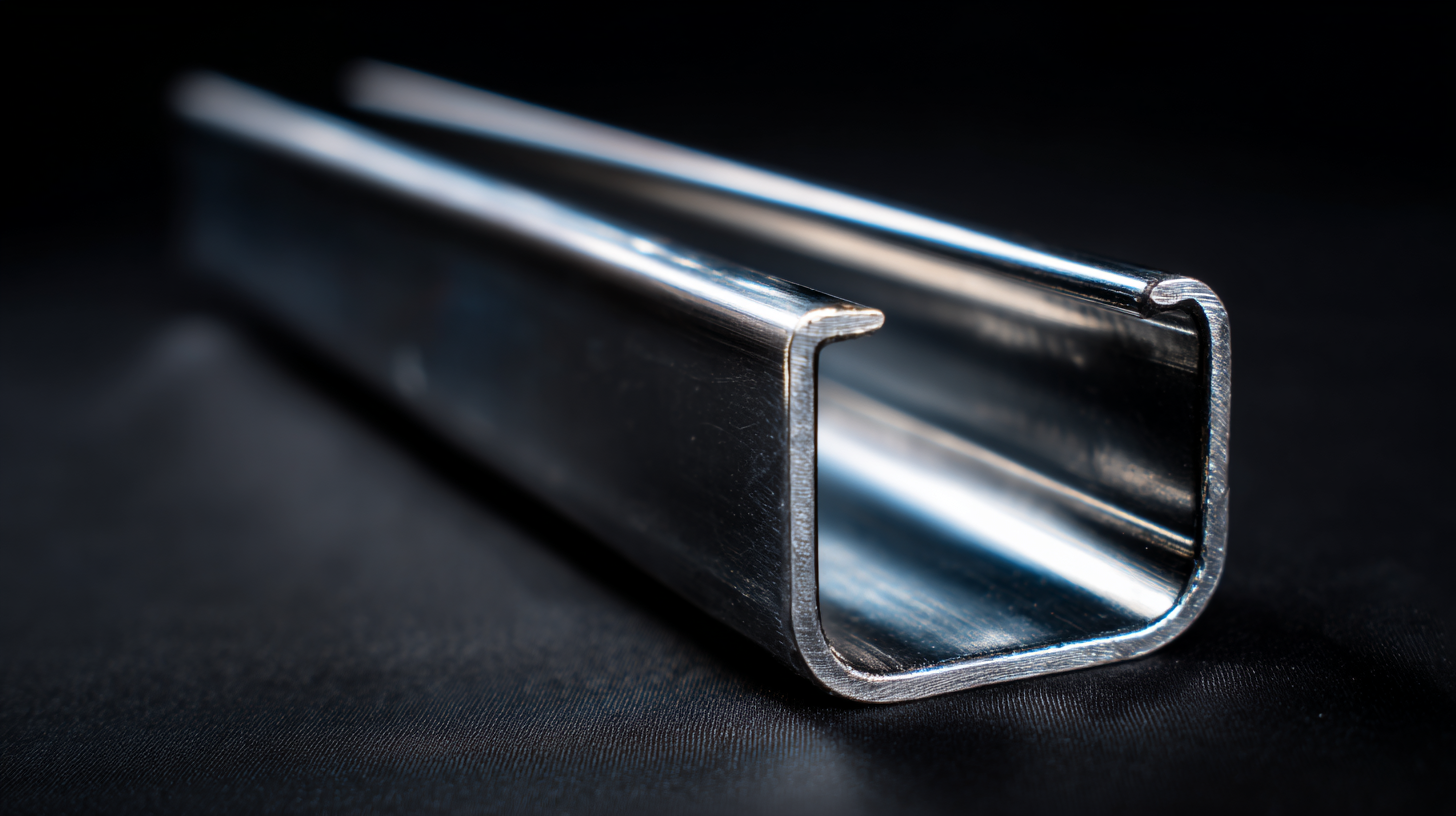

In the ever-evolving landscape of manufacturing and construction, the demand for high-quality materials is paramount to ensure longevity and reliability. Among the myriad options available, the 316 Stainless Steel Channel has emerged as a premier choice, known for its exceptional corrosion resistance and strength. As we look towards the technological advancements anticipated in 2025, it becomes essential for businesses to not only invest in superior materials like the 316 Stainless Steel Channel but also in robust after-sales support. This combination not only maximizes investment returns but also enhances overall project efficiency and sustainability. Understanding the trends in technology development and how they can impact the utilization and maintenance of stainless steel products will be crucial for industry players aiming to stay ahead in a competitive market.

The production and technology of 316 stainless steel channels is poised for transformation as we approach 2025, driven by increasing demand across various sectors such as construction, automotive, and energy. A recent report by Mordor Intelligence highlights a projected growth in the stainless steel market, expecting a compound annual growth rate (CAGR) of 5.3% from 2020 to 2025. This surge is largely attributed to the material's superior corrosion resistance and durability, making it an ideal choice in environments exposed to harsh chemicals and extreme temperatures.

Emerging technological advancements also play a critical role in this evolution. Innovations in manufacturing processes, such as automated laser cutting and advanced welding techniques, are not only enhancing production efficiency but also improving the structural integrity of 316 stainless steel channels. Moreover, the integration of Industry 4.0 practices—including IoT and AI—into steel production promises to streamline operations and reduce waste, ultimately fortifying supply chain resiliency. As manufacturers adapt to these trends, they are expected to offer superior after-sales support, ensuring that clients receive comprehensive service and product reliability that maximize their investment.

Investing in high-quality 316 stainless steel channels offers numerous benefits that can significantly enhance project outcomes. First and foremost, 316 stainless steel is renowned for its excellent corrosion resistance, making it ideal for applications in harsh environments, such as marine and chemical industries. This inherent durability leads to longer product lifespans and reduced maintenance costs, ensuring that projects remain on budget over time. When you invest in high-quality materials, you not only save money in the long run but also improve the overall integrity of your structures.

Another key advantage of high-quality 316 stainless steel channels is their superior structural strength. These channels provide excellent load-bearing capabilities, which is essential for various construction projects. When designed to withstand heavy loads and stresses, this steel type significantly reduces the risk of failure or structural compromise. Moreover, with access to superior after-sales support, customers can benefit from tailored advice and services, ensuring their specific needs are met. This comprehensive support system reinforces the value of your investment, making it easier to address any concerns and optimize the use of your stainless steel channels in diverse applications.

When investing in the best 316 stainless steel channels, assessing after-sales support can significantly impact your overall satisfaction and long-term value. Here’s an essential checklist to ensure you receive top-notch support for your investment.

First, verify the availability of customer service representatives. A reliable supplier should offer multiple channels of communication, such as phone, email, or live chat. Quick response times can prevent minor issues from escalating and ensure that your projects progress smoothly.

Secondly, evaluate the warranty and return policies presented by the manufacturer. A robust warranty indicates the confidence a company has in its products. Ensuring that you have the option to return or exchange defective items is crucial for maintaining your project’s integrity and minimizing potential losses.

Lastly, consider the training and technical support that accompanies your investment. Suppliers that offer guidance on installation and maintenance can help you maximize the performance of your stainless steel channels. This not only enhances your product's longevity but also empowers you and your team with the knowledge required for optimal utilization.

When considering stainless steel alloys, 316 stainless steel stands out due to its superior corrosion resistance and durability, particularly in harsh environments. It contains molybdenum, which enhances its resistance to pitting and crevice corrosion, making it the preferred choice for marine applications and chemical processing. In contrast, other stainless steel alloys, such as 304, may not withstand exposure to chlorides or saline conditions as effectively, potentially leading to premature failure.

**Tip:** When selecting the right alloy for your project, assess the specific environmental conditions the material will face. If you're working near saltwater or in chemically aggressive settings, 316 stainless steel's properties can provide long-term economic benefits.

Moreover, the versatility of 316 stainless steel expands beyond just structural integrity; its aesthetic appeal makes it a suitable option for architectural applications as well. By utilizing 316 alloys in your designs, you can prevent the need for frequent replacements or maintenance associated with inferior materials.

**Tip:** Always consult with suppliers to ensure you’re getting high-quality 316 stainless steel. Take note of after-sales support as it can be crucial for addressing any installation or product issues down the line.

In today's competitive market, nurturing strong business relationships through superior after-sales support is essential for maximizing investments in products like 316 stainless steel channels. A strategic approach to enhancing customer relationship management (CRM) can lead to significant improvements in customer satisfaction and retention. According to recent studies, companies that implement comprehensive CRM systems see a 30% increase in customer retention rates, which directly correlates to a boost in profitability. Fostering a culture focused on customer experience not only helps businesses stand apart but also amplifies brand loyalty.

Moreover, the integration of AI-enabled customer service tools can greatly enhance engagement and address client needs more effectively. Research indicates that businesses leveraging advanced technologies see a 20% increase in overall customer satisfaction. By actively listening to customer feedback through various channels, companies can refine their services, ensuring they meet evolving expectations. In an environment where experiences drive purchases, providing exceptional after-sales support becomes a key differentiator, allowing businesses to not only retain existing clients but also attract new ones through positive word-of-mouth and referrals.

| Dimension | Weight per Foot (lbs) | Common Applications | After Sales Support Rating |

|---|---|---|---|

| 1 x 1 x 0.086 inch | 0.72 | Frames, Railing | 4.5/5 |

| 1.5 x 1.5 x 0.090 inch | 1.06 | Supports, Bracing | 4.7/5 |

| 2 x 2 x 0.100 inch | 1.39 | Construction, Machinery | 4.6/5 |

| 3 x 3 x 0.120 inch | 1.78 | Marine Applications, Structural | 4.8/5 |