Leave Your Message

When it comes to ensuring the safety and durability of elevators, one of the most critical components is the Elevator Steel Wire Rope. This specialized rope is essential for lifting and lowering elevator cabins smoothly and securely, making it vital for the overall function of the system. As elevators are a common feature in commercial and residential buildings, selecting the right Elevator Steel Wire Rope is crucial not only for operational efficiency but also for safety in everyday use.

Choosing the right Elevator Steel Wire Rope involves considering several factors that affect its performance and longevity. The material composition, tensile strength, and resistance to wear are just a few of the aspects that must be understood to make an informed decision. Furthermore, the right choice ensures compliance with safety standards and minimizes the risk of accidents, thereby protecting both passengers and property. This guide will explore the top 10 tips for selecting the optimal Elevator Steel Wire Rope, focusing on the attributes that contribute to enhanced safety and durability in elevator systems.

When selecting elevator steel wire rope, understanding the specifications is crucial for ensuring the safety and durability of the installation. The most significant factors in these specifications include the rope diameter, construction type, and the material used. According to the International Organization for Standardization (ISO), the diameter of the wire rope impacts its tensile strength and overall performance, with larger diameters typically offering higher load capacities. For heavy-duty elevators, ropes with a minimum diameter of 8mm to 12mm are recommended, as studies have shown they can effectively handle the stress associated with high-frequency elevator operations.

Another important specification to consider is the construction type of the wire rope. The two most common types are laid ropes and stranded ropes, with the latter providing greater flexibility and resistance to wear. A report published by the International Association of Elevator Engineers found that stranded ropes can outperform laid ropes in environments with significant movement and strain, reducing the risk of premature failure—an occurrence that can lead to serious safety hazards. Additionally, the material composition of the wire rope plays a pivotal role in its longevity; steel with a higher nickel content can enhance corrosion resistance, essential for elevators installed in harsh environments.

Lastly, it's vital to consider the wire rope's breaking load and minimum safety factor. The American Society of Mechanical Engineers (ASME) suggests that the minimum safety factor for elevator ropes should be around 7:1, meaning the rope can withstand seven times the maximum working load. Ensuring that these specifications meet or exceed industry standards not only promotes the longevity of the elevator system but also safeguards against potential accidents.

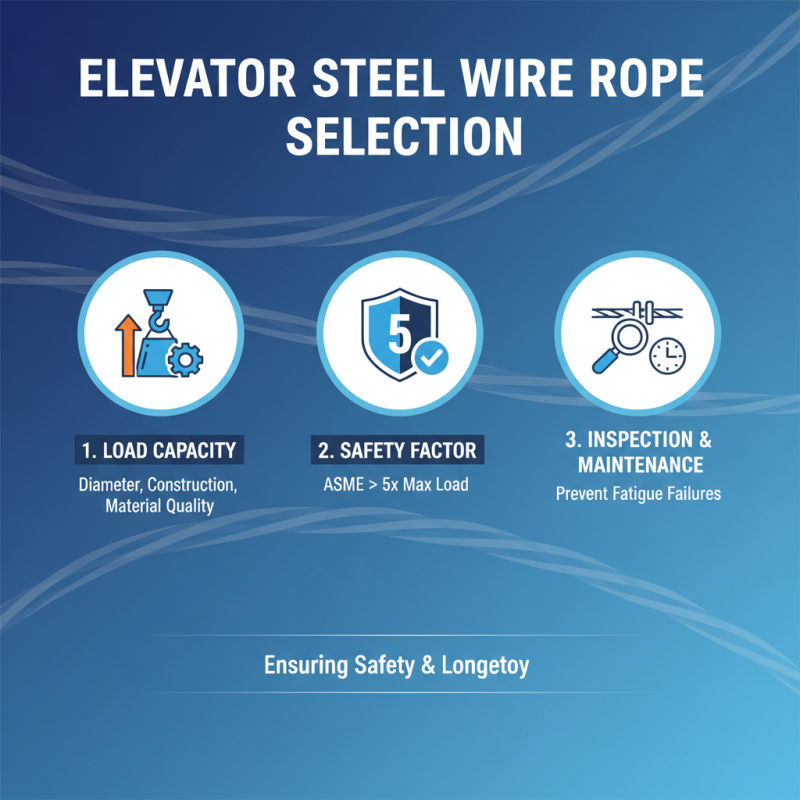

When selecting elevator steel wire ropes, evaluating load capacity and safety standards is paramount to ensure both safety and longevity. According to industry guidelines, the load capacity of steel wire rope is determined by its diameter, construction, and material quality, which must align with the specific requirements of the elevator system. The American Society of Mechanical Engineers (ASME) recommends a safety factor of at least 5 for lifting applications, meaning that the rope should be able to withstand five times the maximum intended load. Regular inspections and maintenance protocols must also align with these standards to prevent fatigue failures.

In addition to load capacity, adherence to safety standards established by recognized organizations, such as the International Organization for Standardization (ISO) and the European Committee for Standardization (CEN), is essential. These organizations provide comprehensive standards that dictate the quality and performance criteria for steel wire ropes, including tensile strength and resistance to environmental factors. For example, ISO 4344 outlines the classifications for steel wire ropes used in elevators, ensuring they meet rigorous performance levels under various operating conditions. As it stands, an estimated 30% of elevator accidents can be attributed to improper rope maintenance or failing to meet established safety specifications. This underscores the importance of choosing the right wire rope, not just for compliance, but for the overall safety of both operators and passengers.

When selecting an elevator steel wire rope, understanding the durability factors of the material is paramount. The composition of the wire rope plays a critical role in its overall strength and longevity. Typically, high carbon steel is favored for its exceptional tensile strength, which ensures that the rope can withstand heavy loads and resist wear over time. Additionally, the wire’s construction—whether it's compacted, spun, or braided—affects its flexibility and resistance to bending fatigue, making it crucial to choose a construction method that aligns with the specific application and environmental conditions.

Another essential durability factor is the presence of corrosion resistance in the wire rope material. Exposure to moisture and various pollutants can significantly weaken steel components, leading to premature failure. Utilizing wire ropes with protective coatings or those made from stainless steel can enhance their resistance to corrosion and extend their service life. Moreover, regular maintenance and inspections are necessary to identify signs of wear or environmental damage early, ensuring that the wire rope maintains its integrity and safety standards throughout its use.

This chart illustrates the durability scores of various types of elevator steel wire ropes. Higher scores indicate better safety and durability, essential factors to consider when selecting the right wire rope for elevator applications.

When selecting elevator steel wire rope, the coating and treatments applied to the rope are critical factors that significantly influence its longevity and performance. A study by the International Organization for Standardization (ISO) indicates that corrosion is one of the leading causes of wire rope failure, accounting for approximately 70% of all failures in harsh environments. Therefore, choosing a wire rope with a robust protective coating can extend its lifespan and enhance safety.

Common coatings include zinc plating, which provides a sacrificial layer against corrosion, and polymer coatings, which offer improved resistance to environmental factors and wear.

Moreover, treatments such as lubrication and heat treatment further enhance the durability of wire ropes. According to the American Society of Mechanical Engineers (ASME), properly lubricated wire ropes can reduce friction and wear, minimizing the risk of breaking under load.

Heat treatment processes can also increase tensile strength, making the wire more resilient under stress. Research conducted by the Wire Rope Technical Committee emphasizes that wire ropes subjected to these treatments show an increase in operational life of up to 30%, thus providing both safety and cost-effectiveness for elevator systems. By prioritizing the right coatings and treatments, operators can ensure reliable and long-lasting performance of elevator steel wire ropes.

When selecting elevator steel wire ropes, the reputation of the manufacturer plays a crucial role in ensuring both safety and durability. A manufacturer with a proven track record is more likely to produce high-quality products that comply with industry standards. It's important to research potential manufacturers, looking into their history, customer reviews, and any certifications they hold. A strong reputation often reflects a commitment to rigorously testing their products and adhering to safety regulations.

Tip: Always prioritize manufacturers who have a history of innovation and quality in their production processes. This can include evaluating their materials, testing methods, and the technology they use to ensure consistency and reliability in their wire ropes.

Compliance with regulations cannot be overlooked when choosing elevator steel wire ropes. Manufacturers should comply with relevant safety standards and guidelines set by industry bodies. This not only ensures the longevity of the wire ropes but also minimizes risks associated with elevator operations. Verifying the certifications of the steel wire ropes can provide additional peace of mind regarding their suitability for safe use.

Tip: Seek out detailed documentation about the compliance of wire ropes with safety standards, and ensure that the manufacturer provides transparent information about their practices. This diligence contributes significantly to selecting wire ropes that can withstand heavy usage while maintaining optimal safety levels.

| Tip | Description | Material Quality | Load Capacity (kg) | Safety Certification |

|---|---|---|---|---|

| 1. Consider Manufacturer Reputation | Choose makers with a long-standing history and positive reviews. | High-grade stainless steel | 5000 | ISO 9001 |

| 2. Check for Compliance with Local Regulations | Ensure ropes meet relevant safety codes. | Galvanized steel | 3000 | EN 13414 |

| 3. Select the Right Diameter | Diameter affects load handling and tensile strength. | Carbon steel | 2500 | ASTM A1023 |

| 4. Evaluate Durability | Long-lasting wire ropes reduce replacement frequency. | Premium aluminum coating | 7000 | UL Listed |

| 5. Weight Considerations | Lighter ropes can improve efficiency. | Super lightweight composite | 4000 | CE Marked |

| 6. Inspect Wire Rope Structure | Different structures affect flexibility and strength. | Braided | 6000 | OSHA Compliant |

| 7. Assess Environmental Resistance | Ropes should resist corrosion and wear. | Corrosion-resistant alloy | 5500 | ISO 14001 |

| 8. Consider User Specifics | Match rope specifications to installation requirements. | Hi-strength steel | 3500 | BIS Certified |

| 9. Investigate Testing Procedures | Ropes should be rigorously tested for quality assurance. | Industry standard | 4500 | TÜV SÜD Certified |

| 10. Consult with Experts | Engage professionals for optimal selection advice. | Custom formulations | 5000 | RINA Approved |