Leave Your Message

In the ever-evolving landscape of heavy lifting solutions, the role of Hoisting Wire Rope has become increasingly crucial. As industries worldwide seek to enhance operational efficiency and safety, innovative technologies in hoisting equipment are paving the way for significant advancements. The year 2025 promises to showcase groundbreaking innovations that not only improve the functionality of Hoisting Wire Rope but also revolutionize the way heavy loads are lifted and managed across various sectors.

Amidst this technological revolution, we will explore the top five innovations set to redefine the standards of heavy lifting. These advancements not only address the challenges faced by engineers and operators but also integrate modern digital solutions that ensure precision, reliability, and safety. By leveraging state-of-the-art materials and smart technologies, these innovations hold the potential to transform traditional lifting practices, offering enhanced durability and performance in demanding environments. As we delve into each of these game-changing developments, it becomes clear that the future of Hoisting Wire Rope is not just about lifting heavier; it’s about lifting smarter.

Innovative materials are transforming the hoisting wire rope industry, driving significant enhancements in strength and durability. The demand for advanced solutions such as plastic-coated wire ropes is rising, driven by their ability to withstand harsh environmental conditions while maintaining superior performance. According to recent market analysis, the global steel wire rope market is projected to reach approximately $13.88 billion by 2030, highlighting the increasing importance of high-quality materials in heavy lifting applications.

The synthetic ropes market is also experiencing notable growth, with a projected CAGR of 7.0% over the coming years. This surge is propelled by advancements in rope technology and materials like polypropylene, polyester, and nylon, which provide exceptional tensile strength and resistance to abrasion. Innovations such as the Konecranes next-generation S-series crane, which incorporates synthetic rope, demonstrate how technological advancements are setting new benchmarks for efficiency and safety in industrial lifting operations. As these materials continue to evolve, their role in modern hoisting solutions becomes ever more critical, promising a future of enhanced durability and reliability for heavy lifting equipment.

This chart illustrates the performance improvements achieved by recent innovations in hoisting wire ropes, focusing on enhanced strength and durability.

The integration of smart sensors into heavy lifting solutions is transforming the landscape of hoisting technologies.

These advanced sensors enable real-time monitoring of crucial parameters such as load weight, environmental conditions, and equipment fatigue.

By leveraging data analytics and artificial intelligence, these innovations significantly enhance operational safety and efficiency.

Operators can receive instant alerts about potential issues, allowing for prompt corrective actions and minimizing the risk of accidents during heavy lifting operations.

As industries push towards more connected and intelligent systems, the demand for cutting-edge sensor technology continues to grow.

The automation of monitoring processes fosters not only safety but also streamlines operations, leading to cost savings and improved productivity.

With the ability to gather and analyze vast amounts of data, these sensors pave the way for smarter decision-making in hoisting applications, ultimately revolutionizing heavy lifting solutions for the future.

The evolution of hoisting wire rope technology is paving the way for eco-friendly solutions within the heavy lifting industry. As demand for sustainable practices grows, manufacturers are increasingly turning to innovative materials and processes. According to a report by Grand View Research, the global wire rope market is expected to grow significantly, reaching USD 2.6 billion by 2025, largely driven by advancements in environmentally responsible manufacturing techniques.

One remarkable innovation includes the use of high-performance synthetic fibers, which not only enhance strength but also reduce environmental impact. By replacing traditional steel wire ropes with these materials, companies can decrease energy consumption and minimize the carbon footprint during production. Additionally, employing sustainable sourcing for raw materials ensures that the entire supply chain takes part in this green revolution.

Tips: When considering lifting solutions, prioritize suppliers who offer eco-friendly wire rope options. Look for certifications that indicate sustainable practices, as well as performance data that highlights durability and effectiveness. Moreover, regular maintenance of your existing equipment can extend its lifespan, further contributing to sustainability efforts. Implementing these tips can significantly influence your company's environmental impact while maintaining operational efficiency.

| Innovation | Description | Advantages | Sustainability Features |

|---|---|---|---|

| High-Strength Synthetic Rope | Rope made from advanced synthetic fibers offering high tensile strength and low weight. | Lightweight, corrosion-resistant, and flexible for easier handling. | Made from recycled materials and can be recycled after use. |

| Biodegradable Wire Coatings | Coatings that degrade naturally over time, minimizing environmental impact. | Reduced environmental hazards and improved safety. | Manufactured with plant-based materials. |

| Smart Wire Rope Technology | Incorporates sensors for monitoring tension and wear in real-time. | Improved operational efficiency and safety through predictive maintenance. | Encourages longer life span and reduces waste. |

| Eco-Friendly Alloy Steel | Manufactured using low-impact materials and processes. | High durability and reduced emissions during production. | Developed in compliance with environmental standards. |

| Hybrid Rope Composites | Combination of steel and synthetic materials for optimum performance. | Enhanced strength-to-weight ratio and flexibility. | Minimizes resource use and energy during production. |

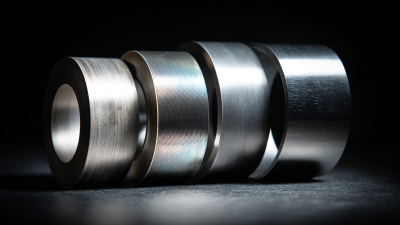

The demand for higher performance in heavy lifting applications has prompted significant innovations in hoisting wire rope, particularly through advanced coating techniques. Recent industry reports indicate that the global wire rope market is projected to grow from $3.5 billion in 2022 to approximately $4.6 billion by 2027, underscoring an increasing need for durability and longevity in lifting solutions. Advanced coatings, such as polymer and ceramic layers, have been developed to enhance wear resistance, significantly extending the operational life of wire ropes used in harsh environments.

These innovative coatings not only resist abrasion but also provide protection against corrosion, which is critical in industries such as construction and marine operations, where environmental factors can lead to equipment degradation. Studies have shown that wire ropes with advanced coatings can offer up to 50% longer service life compared to traditional options, making them a cost-effective choice for businesses looking to reduce maintenance costs and downtime. As a result, companies are increasingly adopting these cutting-edge technologies to optimize their lifting systems and improve overall efficiency.

In recent years, automation has emerged as a cornerstone in enhancing the efficiency of lifting operations, particularly in the hoisting wire rope industry. By integrating advanced control systems, operations are streamlined, reducing the risk of human error and increasing productivity. These innovative technologies enable real-time data monitoring, allowing operators to make informed decisions on-the-fly. Equipment can be programmed for various tasks, ensuring optimal performance across diverse lifting scenarios while minimizing downtime.

Tips for Implementing Automation in Lifting Operations:

These advancements in control systems not only optimize lift operations but also pave the way for future innovations that promise to transform heavy lifting solutions completely.