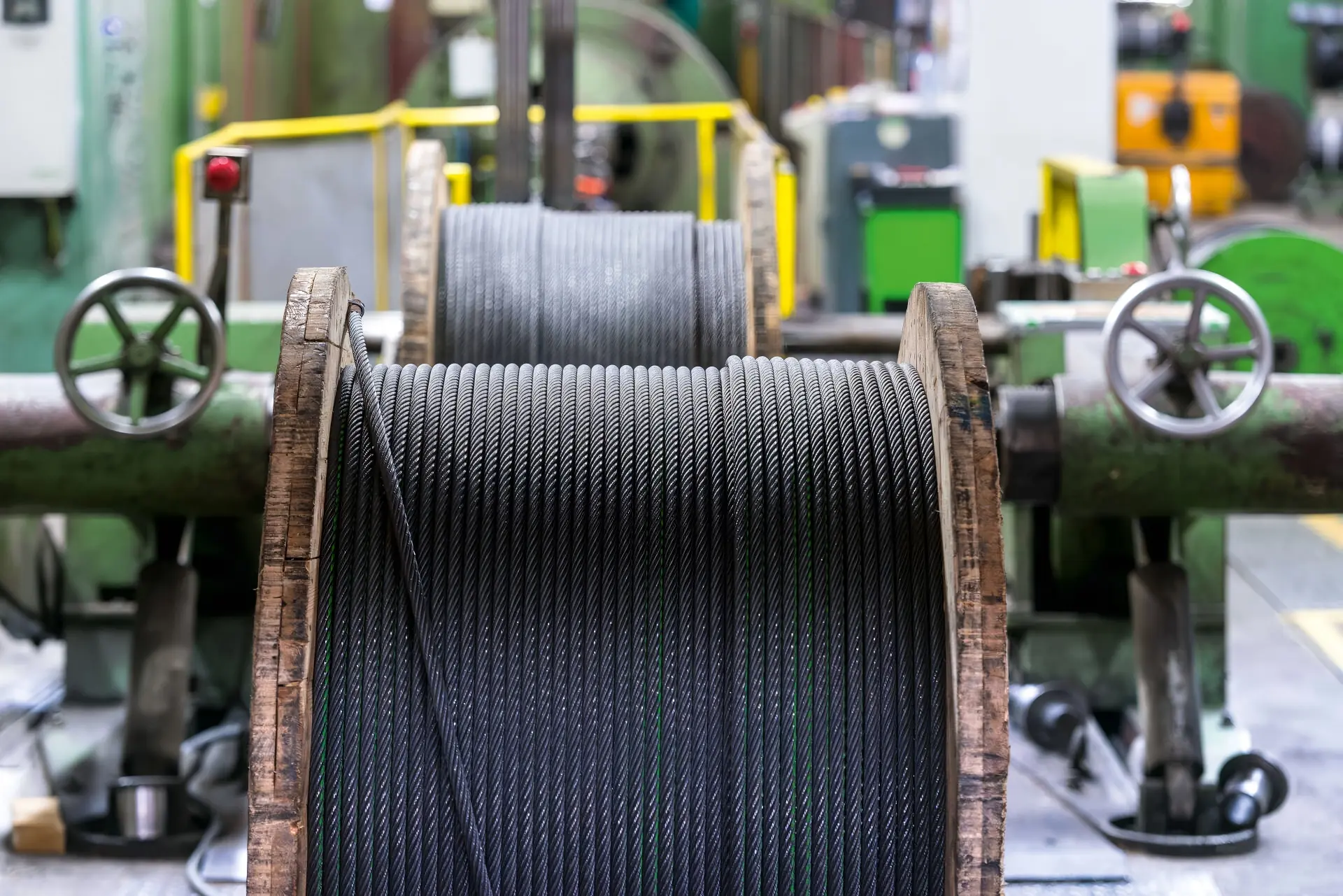

2026 Global Steel Wire Rope Industry White Paper

Low-Carbon Intelligent Manufacturing and Deep-Sea Strategy Lead Industry Reshaping.

[Industry Outlook - London/Beijing/Houston]

As we enter 2026, the global wire rope industry is experiencing its most transformative decade since industrialization. With the digital restart of global supply chains and the stringent constraints of carbon tax policies, the traditional metal products processing industry is undergoing a remarkable transformation towards precision engineering services.

I. Zero-Carbon Supply Chain: Green Premium Reconstructs Trade Barriers

With the deepening implementation of the European Green Trade and national carbon neutrality roadmaps, the core competition in the steel wire rope industry in 2026 has shifted from simply "breaking strength" to "carbon footprint density."

- Deep Application of Green Hydrogen Steel: Industry leaders have begun large-scale procurement of low-carbon hot-rolled wire rods refined from hydrogen energy as raw materials. Data shows that in the first quarter of 2026, the market share of such "green hydrogen steel wire ropes" in the North Sea wind farm construction had climbed to 35%.

- Full Life Cycle Recycling Mechanism:** Leading manufacturers such as Bridon-Bekaert have launched a "closed-loop recycling solution," which achieves efficient identification and secondary refining of waste ropes by embedding special chemical tracking tags in products. This "trade-in" service model not only reduces waste but also saves downstream customers approximately 8% in compliance costs through carbon credits.

II. Internet of Things Empowerment: Wire Ropes Enter the Era of "Digital Twins"

By 2026, wire rope safety assessment had completely moved beyond relying on visual inspection and experience, advancing towards proactive, all-time-domain defense.

- Embedded Intelligent Sensing Technology: The latest "smart wire ropes" incorporate fiber optic sensors or electromagnetic induction cores precisely during the twisting process. This allows the rope to perceive stress distribution, internal wire breakage, and localized corrosion in real time.

- Predictive Maintenance (PdM): Combined with AI algorithms, current digital lifting systems can accurately calculate the "remaining safe life" of wire ropes based on historical load data. After introducing this technology, a large deep-water port reduced its unexpected downtime for maintenance by 42%. This shift from "periodic rope replacement" to "condition-based rope replacement" significantly optimized the company's operational leverage.

III. Offshore Engineering and Extreme Environments: The Technological Battle in the Deep Blue

In 2026, with the global commercialization of deep-sea mineral resource extraction (such as polymetallic nodules), the technical specifications of special steel wire ropes were once again refreshed.

- Ultra-Deep-Sea Lifting Technology: To meet the needs of operations at depths above 6,000 meters, the new "hybrid structure compensation rope," launched in 2026, employs a composite twisting process of high-strength steel wire and synthetic fibers.

- Technical Highlights: This design solves the problem of "self-weight collapse" of steel wire ropes over ultra-long distances. While maintaining extremely high axial strength, it reduces the self-weight in water by 30%, making operations at depths of 10,000 meters possible.

- Breakthrough in Corrosion-Resistant Coating: New nano-polymer coating technology not only enhances the rope's wear resistance but also prevents seawater from seeping into the core under extreme high-pressure environments in the deep sea, extending the replacement cycle of offshore crane steel wire ropes from an average of 18 months to 36 months.

IV. Market Landscape: From "Selling Products" to "Selling Reliability"

The market competition in 2026 exhibited a clear "polarization":

- High-end Servitization: Top manufacturers no longer simply quote prices per ton, but offer comprehensive contracting solutions based on "capacity per million tons." This model deeply links manufacturing profits with customer production efficiency.

- Supply Chain Resilience Restructuring: Affected by geopolitical fluctuations, a significant "nearshore outsourcing" trend emerged in the industry in 2026. Large groups established highly automated micro-factories at key global nodes (such as Southeast Asia, Mexico, and the Middle East) to achieve customized responses within 48 hours, replacing the previous weeks-long sea freight delivery.

Conclusion:

In 2026, the wire rope industry was no longer seen as a sunset industry, but rather an indispensable "neural network" in the digital transformation of infrastructure, energy, and mining. Innovation, low carbon, and intelligence have become the new genes of this ancient industry in the digital age.