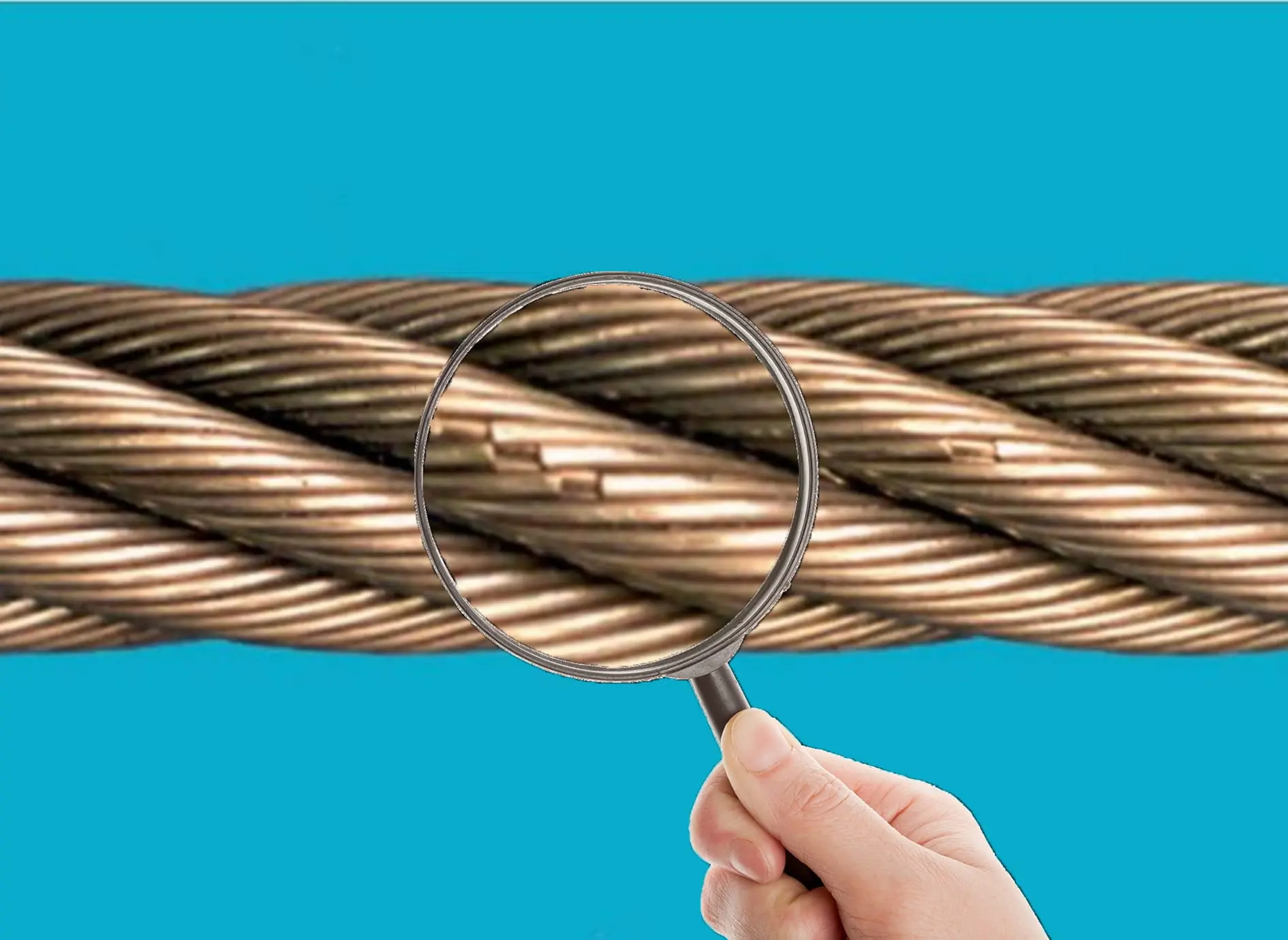

How to choose between hot-dip galvanized steel wire rope and electro-galvanized steel wire rope?

The choice between hot-dip Galvanized Steel Wire Rope and electro-galvanized steel wire rope depends on many factors, including the use environment, expected life, budget, and required mechanical properties. The following is a detailed comparison of the two types of steel wire ropes to help you make a more appropriate choice:

1. Galvanizing process

-Hot-dip galvanizing:

The steel wire rope is immersed in molten zinc liquid to form a thicker zinc layer.

An alloy layer is formed between the zinc layer and the steel matrix, and the adhesion is strong.

-Electro-galvanizing:

A layer of zinc is deposited on the surface of the steel wire rope by electrochemical method.

The zinc layer is relatively thin and the adhesion is not as good as hot-dip galvanizing.

2. Corrosion resistance

-Hot-dip galvanizing:

The zinc layer is thick and has strong corrosion resistance, especially in harsh environments such as humidity and salt spray.

Long service life.

-Electro-galvanizing:

The zinc layer is thin and the corrosion resistance is relatively poor.

Suitable for mildly corrosive environments.

3. Mechanical properties

-Hot-dip galvanizing:

High-temperature galvanizing may have a certain impact on the strength and toughness of the wire rope.

But the impact is usually within an acceptable range.

-Electrogalvanizing:

It has little impact on the mechanical properties of the wire rope.

Usually, the strength of the electrogalvanized wire rope is higher than that of the hot-dip galvanized wire rope.

4. Appearance difference

-Hot-dip galvanizing:

The surface is relatively rough and the color is dark.

-Electrogalvanizing:

The surface is smooth and the gloss is high.

5. Cost

-Hot-dip galvanizing:

The production cost is high.

-Electrogalvanizing:

The production cost is low.

6. Application scenarios

-Hot-dip galvanizing:

Suitable for highly corrosive environments such as outdoor, marine, and chemical industries.

Such as bridges, ships, mines, electricity, etc.

-Electrogalvanizing:

Suitable for mildly corrosive environments such as indoor and dry environments.

Such as construction, machinery, agriculture, etc.

Summary:

If high corrosion resistance and long life are required, choose hot-dip galvanized wire rope.

If you have requirements for appearance and the use environment is not highly corrosive, choose electro-galvanized steel wire rope.

If you have high requirements for strength, choose electro-galvanized steel wire rope.

When choosing, you should also consider factors such as the diameter, structure, and strength of the steel wire rope, and refer to relevant standards and specifications.