Load Limits and Practical Safety Guidelines for Wire Rope Slings

In the field of heavy lifting, the line between safe operation and major accidents is often very thin.

This difference depends not only on the quality of the equipment but also on the operator's deep understanding of the working load limit (WLL).

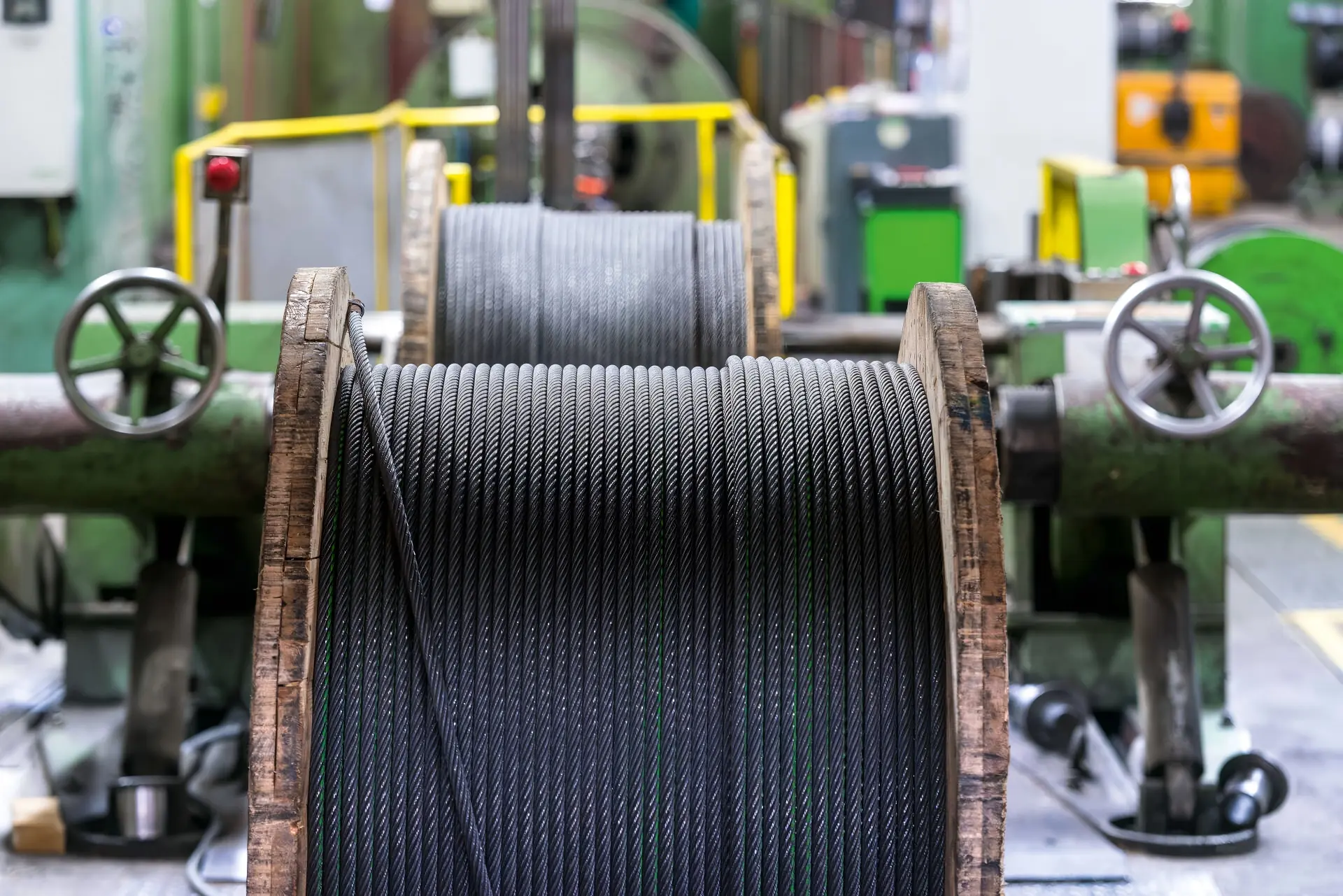

As a core tool in industrial lifting, wire rope slings, while powerful, can easily lead to catastrophic consequences if improperly selected or overloaded.

As a Supplier of high-performance wire rope solutions,Meishen Wire Rope understands that even the strongest slings can become safety hazards if used improperly.

This guide will help you build a comprehensive lifting safety system by analyzing load factors, environmental impacts, and practical techniques.

I. Core Concepts: Load Limits and the Essence of WLL

In the rigging field, there are two crucial parameters:

(1) Minimum Breaking Strength (MBS): This is the limit value at which a sling will completely break under laboratory conditions.

(2) Working Load Limit (WLL): This is the absolute safety red line that must not be crossed in actual operations.

Calculation Logic:

WLL = MBS / Safety Factor SF

Typically, the standard safety factor for industrial hoisting is set at 5:1. This means that if the breaking force of a sling is 50 tons, its rated load is only 10 tons.

This extra four times the capacity is to withstand impact loads, material fatigue, and unpredictable dynamic tension.

II. Five Key Variables Determining Load Capacity

Even with the same specifications, slings perform very differently in different scenarios. The following factors directly determine the actual strength of the sling:

(1) Internal structural differences: For example, 6x19 or 6x36 structures. Slings designed with compacted struts have a larger metal cross-sectional area and therefore stronger load capacity;

while multi-layer anti-rotation structures are more suitable for long-distance hoisting at high altitudes.

(2) Hoisting geometry: This is the most easily overlooked killer. When the angle between the two legs increases, the tension on each leg increases exponentially.

When the included angle reaches 120°, the tension on the sling equals the total load weight, and the safety margin is quickly exhausted.

(3) Load Shape and Protection: Sharp edges create a "shear effect," instantly damaging the steel wire fibers. Using sling protectors or sleeves is a mandatory requirement for extending sling life.

(4) Environmental Corrosion: Extreme high temperatures, acid and alkali corrosion, or high-salt spray marine environments can alter the molecular properties of steel.

In these environments, galvanized or stainless steel materials must be selected, and the WLL (weightless lay length) should be appropriately reduced.

III. Safety Inspection and Maintenance in Practice

"One-minute checks before lifting" can save countless lives. According to ASME and ANSI standards, the following signs mean the sling must be scrapped immediately:

(1) Visible Broken Wires: The number of broken wires within one lay exceeds the standard limit.

(2) Geometric Deformation: Kinking, flattening, or cage-like distortion occurs.

(3) Diameter Reduction: Wear causes a diameter reduction exceeding 7% of the nominal value.

(4) End Damage: Cracks appear in the pressed joint, or the wire rope shows signs of slippage at the eyelet.

IV. Expert Recommendations for Maintaining Work Capacity

Scientific Storage: Avoid direct contact with the ground; store in a dry, well-ventilated place to prevent internal corrosion.

Regular Lubrication: Use professional wire rope lubricant to reduce inter-strand friction.

Mandatory Disposal System: Establish a ledger to destroy slings that have reached their fatigue cycle, preventing them from re-entering the work site.

Summary

Mastering Working Load Capacity (WLL) is not a simple mathematical problem, but the cornerstone of safe production.

Meishen Wire Rope not only provides top-notch products but is also committed to providing you with professional engineering support.